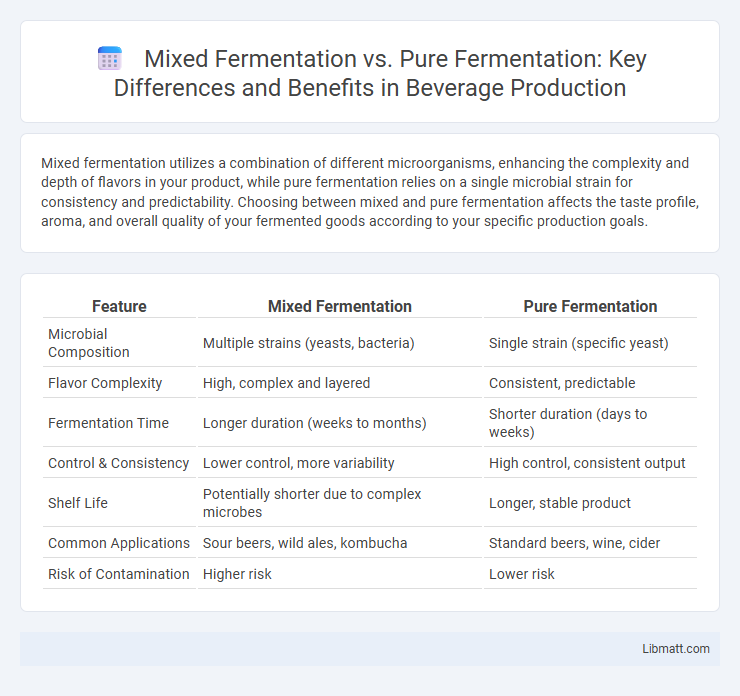

Mixed fermentation utilizes a combination of different microorganisms, enhancing the complexity and depth of flavors in your product, while pure fermentation relies on a single microbial strain for consistency and predictability. Choosing between mixed and pure fermentation affects the taste profile, aroma, and overall quality of your fermented goods according to your specific production goals.

Table of Comparison

| Feature | Mixed Fermentation | Pure Fermentation |

|---|---|---|

| Microbial Composition | Multiple strains (yeasts, bacteria) | Single strain (specific yeast) |

| Flavor Complexity | High, complex and layered | Consistent, predictable |

| Fermentation Time | Longer duration (weeks to months) | Shorter duration (days to weeks) |

| Control & Consistency | Lower control, more variability | High control, consistent output |

| Shelf Life | Potentially shorter due to complex microbes | Longer, stable product |

| Common Applications | Sour beers, wild ales, kombucha | Standard beers, wine, cider |

| Risk of Contamination | Higher risk | Lower risk |

Introduction to Fermentation Processes

Mixed fermentation involves multiple microbial species working simultaneously, enhancing flavor complexity and improving product diversity in food and beverage production. Pure fermentation employs a single, well-characterized microorganism, offering consistent and controlled results ideal for industrial applications like ethanol or yogurt production. Understanding the distinct microbial dynamics and metabolic pathways in each process is crucial for optimizing fermentation efficiency and product quality.

Defining Mixed Fermentation

Mixed fermentation involves using multiple strains of yeast and bacteria simultaneously to produce complex flavors and aromas in beverages like beer and wine. Pure fermentation relies on a single, controlled yeast strain to ensure consistency and predictability in taste and quality. Understanding the role of diverse microorganisms in mixed fermentation can help you craft unique, character-rich products that stand out in the market.

What is Pure Fermentation?

Pure fermentation involves the use of a single, specific microorganism strain to convert sugars into alcohol or other desired products, ensuring consistent and controlled results. This method is commonly employed in industries such as winemaking, brewing, and biotechnology where product purity and predictability are crucial. Your fermentation process can achieve greater precision and fewer byproducts through pure fermentation compared to mixed fermentation.

Microbial Diversity: Mixed vs Pure Fermentation

Mixed fermentation leverages a diverse microbial community, including various yeasts and bacteria, enhancing flavor complexity and increasing metabolic byproducts such as organic acids and esters. Pure fermentation relies on a single microbial strain, offering greater control and consistency but often resulting in a narrower flavor profile. Understanding microbial diversity helps you select the best fermentation method to achieve specific quality and sensory goals.

Flavor Profiles and Sensory Differences

Mixed fermentation produces complex flavor profiles by combining wild yeast and bacteria, resulting in sour, funky, and layered sensory notes that pure fermentation lacks. Pure fermentation, relying on a single yeast strain, offers more predictable and cleaner flavors with crisp and straightforward characteristics. Your choice between mixed and pure fermentation impacts the depth and uniqueness of flavor in your final product.

Applications in Food and Beverage Production

Mixed fermentation enhances complexity and flavor profiles in products like sour beers, naturally leavened breads, and traditional fermented foods by utilizing diverse microbial communities. Pure fermentation, relying on specific, controlled strains such as Saccharomyces cerevisiae, ensures consistency and predictability in beverages like wine, beer, and yogurt production. The choice between mixed and pure fermentation directly impacts product characteristics, production scalability, and consumer acceptance in the food and beverage industry.

Advantages of Mixed Fermentation

Mixed fermentation harnesses diverse microbial communities, enhancing flavor complexity and depth in beverages like beer and wine. This process improves resilience against contaminants and fermentation issues due to competitive microbial interactions. The use of mixed cultures can also reduce fermentation time and increase yield efficiency, providing economic benefits to producers.

Benefits of Pure Fermentation

Pure fermentation offers greater control over microbial strains, resulting in consistent flavor profiles and product quality. It reduces the risk of unwanted microbial contamination, improving safety and reproducibility in beverage and food production. Efficiency in fermentation kinetics often leads to shorter production times and higher yields compared to mixed fermentation processes.

Challenges and Considerations in Each Method

Mixed fermentation involves multiple microbial species, creating complex flavor profiles but posing challenges in maintaining consistency and controlling microbial dominance. Pure fermentation uses a single strain, offering more predictable outcomes and easier quality control, but can lack the depth of flavors found in mixed fermentations. Your choice depends on balancing the desire for unique taste complexity with the need for process stability and reproducibility.

Future Trends in Fermentation Technology

Future trends in fermentation technology highlight a growing preference for mixed fermentation due to its ability to enhance flavor complexity and increase production efficiency through synergistic microbial interactions. Advances in metagenomics and synthetic biology enable precise control and optimization of mixed microbial consortia, fostering sustainable bioprocesses and novel bio-products. Meanwhile, pure fermentation remains vital for producing ultra-pure compounds with consistent quality, especially in pharmaceuticals and specialty chemicals, driving integration of automated monitoring and AI-based process control.

Mixed fermentation vs pure fermentation Infographic

libmatt.com

libmatt.com