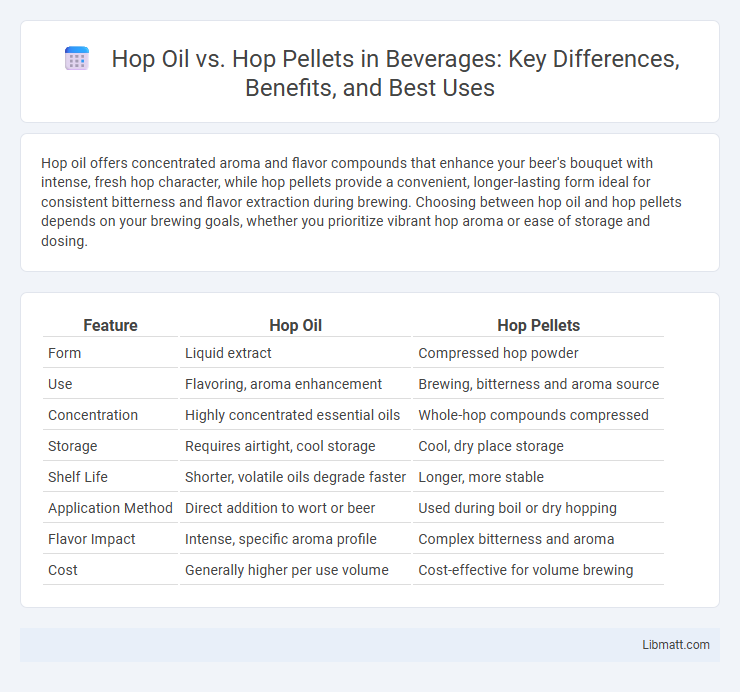

Hop oil offers concentrated aroma and flavor compounds that enhance your beer's bouquet with intense, fresh hop character, while hop pellets provide a convenient, longer-lasting form ideal for consistent bitterness and flavor extraction during brewing. Choosing between hop oil and hop pellets depends on your brewing goals, whether you prioritize vibrant hop aroma or ease of storage and dosing.

Table of Comparison

| Feature | Hop Oil | Hop Pellets |

|---|---|---|

| Form | Liquid extract | Compressed hop powder |

| Use | Flavoring, aroma enhancement | Brewing, bitterness and aroma source |

| Concentration | Highly concentrated essential oils | Whole-hop compounds compressed |

| Storage | Requires airtight, cool storage | Cool, dry place storage |

| Shelf Life | Shorter, volatile oils degrade faster | Longer, more stable |

| Application Method | Direct addition to wort or beer | Used during boil or dry hopping |

| Flavor Impact | Intense, specific aroma profile | Complex bitterness and aroma |

| Cost | Generally higher per use volume | Cost-effective for volume brewing |

Introduction to Hop Oil and Hop Pellets

Hop oil, a concentrated essential oil derived from hops, delivers intense aromatic compounds crucial for brewing distinct beer flavors. Hop pellets are processed hop cones ground into small pellets, preserving the hop's bittering and aromatic properties while offering ease of storage and handling. Your choice between hop oil and hop pellets impacts the flavor profile and brewing efficiency depending on your specific beer recipe and production scale.

What Are Hop Oils?

Hop oils are the essential oils extracted from hops that contribute to the aroma and flavor profile of beer. These volatile compounds are responsible for various sensory notes such as citrus, pine, floral, and spicy characteristics. Understanding hop oils allows brewers to optimize your beer's taste by selecting either whole hop oils for intense aroma or hop pellets for consistency and ease of use.

What Are Hop Pellets?

Hop pellets are compressed granules made from ground hop cones, designed to maximize hop storage and brewing efficiency. They contain the essential oils and resins responsible for hop aroma, flavor, and bitterness, preserved through a drying and pelletizing process that extends shelf life. Brewers prefer hop pellets for their consistent quality, ease of measurement, and reduced volume compared to whole leaf hops.

Extraction and Production Processes

Hop oil is extracted through steam distillation or CO2 extraction, capturing volatile aromatic compounds directly from fresh hops, preserving delicate flavors and essential oils. Hop pellets are produced by grinding whole hops into a powder and compressing them, which retains alpha acids and resins but can lead to the loss of some volatile oils during processing. Your choice between hop oil and hop pellets affects the intensity and profile of hop-derived aromas and bitterness in brewing or flavoring applications.

Key Differences in Usage

Hop oil offers a concentrated, aromatic profile ideal for precise flavor adjustments during brewing, while hop pellets provide convenience, longer shelf life, and consistent bitterness levels. You can enhance your brew's aroma with hop oil by controlling the amounts more accurately, whereas hop pellets are better suited for general bitterness and ease of storage. Understanding these key differences helps optimize hop utilization based on your brewing goals and recipe requirements.

Flavor and Aroma Impact

Hop oil delivers a more intense and vibrant aroma compared to hop pellets, as it contains concentrated essential oils responsible for hop's characteristic fragrances. Hop pellets, while providing consistent alpha acids for bitterness, often result in a more subdued and less complex flavor profile due to partial loss of volatile compounds during processing. Breweries seeking robust hop aroma and flavor typically prefer hop oil for dry hopping and late additions in brewing.

Dosage and Efficiency

Hop pellets generally require lower dosage compared to whole hop oil due to their concentrated alpha acids and essential oils, leading to efficient utilization in brewing. Hop oil provides intense aroma and flavor, often used in smaller quantities to maximize impact without overwhelming the beer. Efficiency in hop pellets ensures consistent bitterness and aroma extraction, while hop oil offers targeted flavor enhancement with minimal utilization.

Storage and Shelf Life

Hop oil is more volatile and requires airtight, dark storage at low temperatures to preserve its aromatic compounds and extend shelf life up to 6 months. Hop pellets have a longer shelf life, often lasting 1 to 2 years when stored in vacuum-sealed bags away from heat, light, and oxygen. You can maintain optimal freshness by prioritizing proper storage methods specific to each form, ensuring maximum flavor retention in brewing.

Cost and Availability Comparison

Hop pellets generally offer a more cost-effective option due to their concentrated form, which reduces shipping and storage expenses compared to whole hop oil. Availability of hop pellets is typically higher throughout the year because they have a longer shelf life and are less susceptible to spoilage. You can often find hop pellets more easily in bulk quantities, making them a practical choice for brewers managing budget and inventory.

Choosing the Right Option for Your Brew

Hop oil offers concentrated aroma and flavor characteristics ideal for enhancing craft brews with intense hop profiles, while hop pellets provide ease of storage, consistent bitterness, and extended shelf life, making them suitable for large-scale or homebrewing. Brewers seeking precise control over hop utilization and aroma may prefer hop pellets for their predictable alpha acid content, whereas hop oil is favored for imparting unique essential oils that contribute complexity. Selecting between hop oil and hop pellets depends on the desired flavor intensity, brewing scale, and process control to achieve optimal hop expression in the final product.

Hop oil vs hop pellets Infographic

libmatt.com

libmatt.com