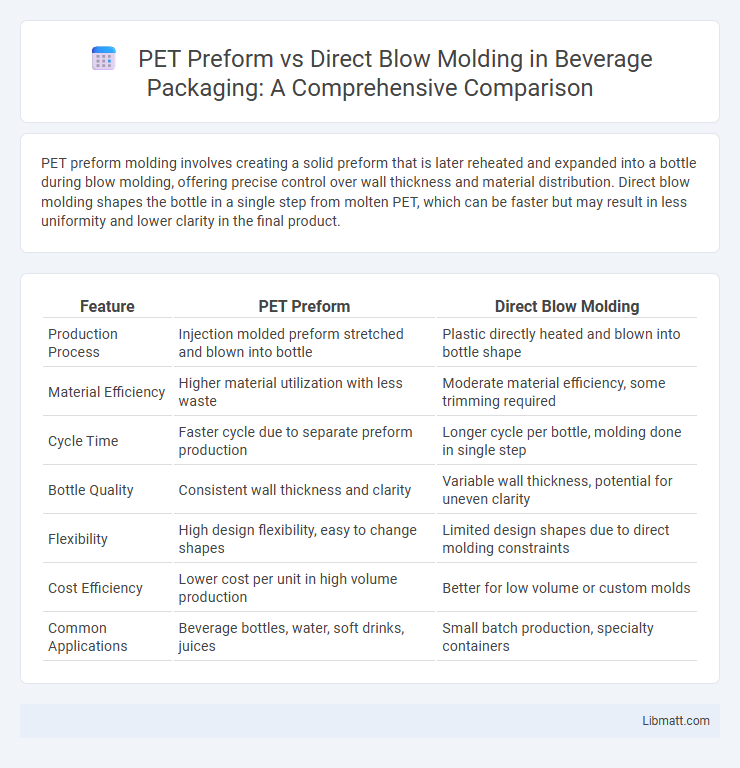

PET preform molding involves creating a solid preform that is later reheated and expanded into a bottle during blow molding, offering precise control over wall thickness and material distribution. Direct blow molding shapes the bottle in a single step from molten PET, which can be faster but may result in less uniformity and lower clarity in the final product.

Table of Comparison

| Feature | PET Preform | Direct Blow Molding |

|---|---|---|

| Production Process | Injection molded preform stretched and blown into bottle | Plastic directly heated and blown into bottle shape |

| Material Efficiency | Higher material utilization with less waste | Moderate material efficiency, some trimming required |

| Cycle Time | Faster cycle due to separate preform production | Longer cycle per bottle, molding done in single step |

| Bottle Quality | Consistent wall thickness and clarity | Variable wall thickness, potential for uneven clarity |

| Flexibility | High design flexibility, easy to change shapes | Limited design shapes due to direct molding constraints |

| Cost Efficiency | Lower cost per unit in high volume production | Better for low volume or custom molds |

| Common Applications | Beverage bottles, water, soft drinks, juices | Small batch production, specialty containers |

Introduction to PET Preform and Direct Blow Molding

PET preform manufacturing involves creating a small, test-tube-shaped piece of polyethylene terephthalate that is later reheated and expanded into bottles using blow molding. Direct blow molding, in contrast, forms PET bottles by directly melting pellets and shaping them into containers in one continuous process, eliminating the preform stage. Your choice between PET preform and direct blow molding impacts production speed, equipment cost, and bottle quality, with preforms offering greater design flexibility and direct blow molding enabling faster cycle times.

Overview of PET Preform Process

The PET preform process involves injection molding molten polyethylene terephthalate into a test-tube shaped intermediate called a preform, which is then reheated and stretched in a blow molding machine to form the final bottle shape. This method offers precise control over material distribution and wall thickness, resulting in consistent, high-quality containers ideal for carbonated beverages and water. The preform process separates the molding and blowing stages, enabling higher production efficiency and flexibility compared to direct blow molding, where the bottle is formed in a single step.

How Direct Blow Molding Works

Direct blow molding involves heating PET resin pellets until they reach a molten state, which is then injected directly into a mold cavity to form the final bottle shape. This process eliminates the need for preform production by combining injection molding and blow molding steps into one continuous operation. The method allows for greater design flexibility and faster cycle times compared to traditional PET preform techniques.

Key Differences Between PET Preform and Direct Blow Molding

PET preform molding involves creating a solid, shaped preform that is later reheated and blown into a bottle in a separate step, while direct blow molding forms the bottle in one continuous process without an intermediate preform. This results in PET preforms offering superior control over thickness distribution and material properties, enhancing bottle strength and clarity. Your choice between these methods depends on production speed requirements, design flexibility, and equipment availability.

Material Efficiency Comparison

PET preform production allows for more precise control over material distribution, minimizing waste compared to direct blow molding, which often results in uneven wall thickness and excess scrap. The preform process optimizes polymer usage by producing standardized shapes that can be reheated and stretched, improving material utilization rates by up to 15%. In contrast, direct blow molding typically requires higher raw material input due to less efficient molding precision and greater trimming losses.

Production Speed and Scalability

PET preform production combined with injection molding offers high production speeds due to rapid cycle times, enabling efficient mass production of uniform preforms. Direct blow molding, while generally slower because of longer cooling periods, simplifies the process by eliminating separate preform manufacturing, which can enhance scalability for lower volume or customized container runs. Industries prioritize preform methods for large-scale operations requiring stringent quality control, whereas direct blow molding suits flexible, moderate-scale applications with faster tool changeovers.

Quality and Consistency of Finished Products

PET preform manufacturing ensures superior quality and consistency in finished plastic containers through precise control over material distribution and molecular orientation during injection molding. This method results in bottles with uniform wall thickness, enhanced clarity, and improved resistance to impact and stress, outperforming direct blow molding's typically less consistent output. Your products benefit from greater reliability and performance when using PET preforms, making them ideal for liquid packaging applications requiring high standards.

Cost Analysis: PET Preform vs Direct Blow Molding

PET preform production generally involves higher initial tooling costs but offers lower per-unit expenses due to economies of scale, making it cost-effective for large production runs. Direct blow molding reduces upfront investments by eliminating the preform step, yet results in higher material waste and slower cycle times, increasing overall costs for high-volume manufacturing. Your choice depends on balancing these cost factors against production volume and product complexity.

Applications and Industry Use Cases

PET preforms are widely used in beverage packaging, including water, soft drinks, and edible oils, allowing manufacturers to achieve high production efficiency and consistent bottle quality. Direct blow molding is favored in industries requiring larger or more complex container shapes, such as automotive fluid containers and pharmaceutical packaging, due to its design flexibility and material uniformity. Your choice between PET preform and direct blow molding depends on the specific application requirements and industry standards for durability, clarity, and production volume.

Choosing the Right Method for Your Packaging Needs

Choosing between PET preform and direct blow molding depends largely on production volume and product design requirements. PET preform molding offers precise control over bottle shape and consistency, ideal for high-volume beverage and packaging manufacturers seeking lightweight and durable containers. Direct blow molding suits smaller production runs or custom shapes, providing flexibility but with less uniformity and efficiency compared to PET preform methods.

PET preform vs direct blow molding Infographic

libmatt.com

libmatt.com