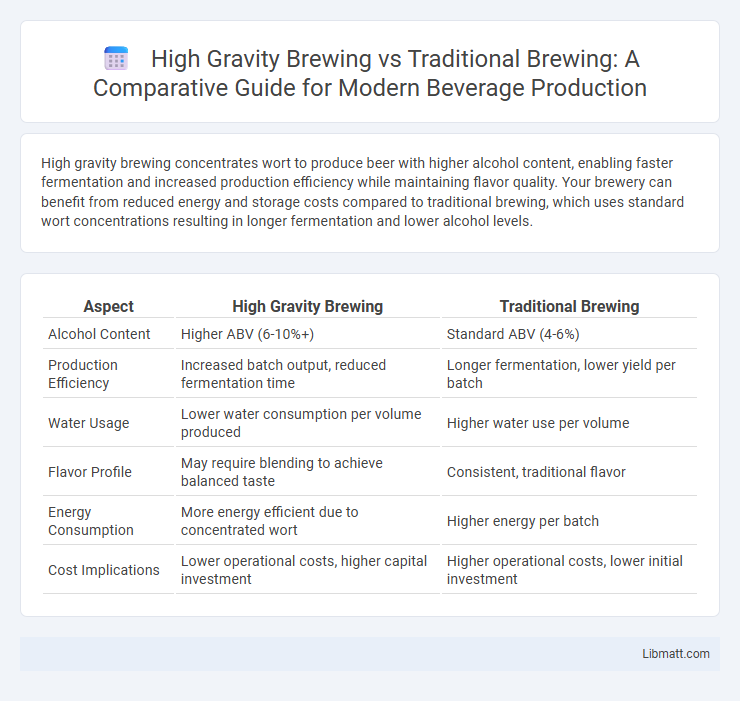

High gravity brewing concentrates wort to produce beer with higher alcohol content, enabling faster fermentation and increased production efficiency while maintaining flavor quality. Your brewery can benefit from reduced energy and storage costs compared to traditional brewing, which uses standard wort concentrations resulting in longer fermentation and lower alcohol levels.

Table of Comparison

| Aspect | High Gravity Brewing | Traditional Brewing |

|---|---|---|

| Alcohol Content | Higher ABV (6-10%+) | Standard ABV (4-6%) |

| Production Efficiency | Increased batch output, reduced fermentation time | Longer fermentation, lower yield per batch |

| Water Usage | Lower water consumption per volume produced | Higher water use per volume |

| Flavor Profile | May require blending to achieve balanced taste | Consistent, traditional flavor |

| Energy Consumption | More energy efficient due to concentrated wort | Higher energy per batch |

| Cost Implications | Lower operational costs, higher capital investment | Higher operational costs, lower initial investment |

Introduction to High Gravity Brewing

High gravity brewing involves producing beer with a higher original gravity, typically above 1.060, allowing brewers to create concentrated wort that can be diluted later to achieve the desired final alcohol content. This method enhances production efficiency by increasing batch size and maximizing brewery capacity while maintaining consistent flavor profiles. Your brewery can benefit from reduced fermentation times and lower energy costs compared to traditional brewing methods.

Overview of Traditional Brewing

Traditional brewing involves fermenting beer at standard wort gravity, typically ranging from 1.040 to 1.060 specific gravity, which influences alcohol content and flavor profile. This method allows for natural yeast activity without the need for post-fermentation dilution, resulting in a stable and consistent quality. The slower fermentation process in traditional brewing often enhances complexity and depth of flavor compared to high gravity brewing techniques.

Key Differences Between High Gravity and Traditional Brewing

High gravity brewing involves fermenting beer at higher original gravities, typically above 1.070 specific gravity, resulting in higher alcohol content and stronger flavors compared to traditional brewing with gravities around 1.040 to 1.060. This method requires precise yeast management and oxygenation to ensure complete fermentation despite the stress of high sugar concentrations. Traditional brewing prioritizes balanced flavor profiles and shorter fermentation times, while high gravity brewing emphasizes efficiency and increased production volume without compromising quality.

Benefits of High Gravity Brewing

High gravity brewing offers significant advantages including increased production efficiency by fermenting wort with higher sugar concentrations, reducing fermentation time and energy consumption. This method enhances yeast health and performance, leading to improved flavor consistency and product stability compared to traditional brewing. Brewers also benefit from reduced packaging and transportation costs due to concentrated beer volume before dilution.

Challenges in High Gravity Brewing

High gravity brewing presents unique challenges, including managing elevated osmotic pressure that stresses yeast, leading to incomplete fermentation and off-flavors. Controlling temperature and oxygen levels becomes critical to ensure yeast health and optimize attenuation in high-gravity worts. Your brewing process must also accommodate longer maturation times to allow flavors to harmonize and reduce potential solvent-like characteristics linked to higher alcohol content.

Equipment and Process Modifications

High gravity brewing requires specialized equipment such as fermenters and conditioning tanks designed to handle higher wort concentrations and increased osmotic pressure. The process modifications include using more robust yeast strains and carefully controlled fermentation parameters to manage elevated alcohol levels and residual sugars. Traditional brewing relies on standard fermentation vessels and less stringent control of gravity, resulting in longer fermentation times and lower initial extract concentrations.

Impact on Beer Flavor and Quality

High gravity brewing intensifies beer flavor by concentrating fermentable sugars, resulting in a richer and more robust taste compared to traditional brewing. This method can enhance mouthfeel and aroma complexity but requires precise fermentation control to avoid off-flavors such as fusel alcohols. Traditional brewing tends to produce lighter, more balanced flavors with consistent quality, benefiting from longer fermentation times and natural attenuation processes.

Cost and Efficiency Considerations

High gravity brewing significantly reduces production and distribution costs by concentrating wort, which decreases transportation volume and increases fermenter utilization rates. Traditional brewing requires larger vessel capacities and more energy for cooling and fermentation, leading to higher operational expenses. The efficiency gains from high gravity methods allow breweries to produce more beer in less time, optimizing resource use and increasing overall profitability.

Environmental Implications

High gravity brewing significantly reduces water and energy consumption by producing a concentrated wort that is diluted later, leading to lower overall resource usage compared to traditional brewing. This method minimizes wastewater and packaging materials, enhancing your brewery's environmental sustainability. Implementing high gravity techniques contributes to a smaller carbon footprint and supports greener brewing operations.

Choosing the Right Brewing Method

Choosing the right brewing method depends on factors like desired production volume, flavor profile, and operational efficiency. High gravity brewing allows for increased fermentation concentrations, reducing water usage and improving energy efficiency while enabling larger batch sizes. Traditional brewing offers more control over subtle flavor development and is often preferred for craft and artisanal beers with complex taste profiles.

High gravity brewing vs traditional brewing Infographic

libmatt.com

libmatt.com