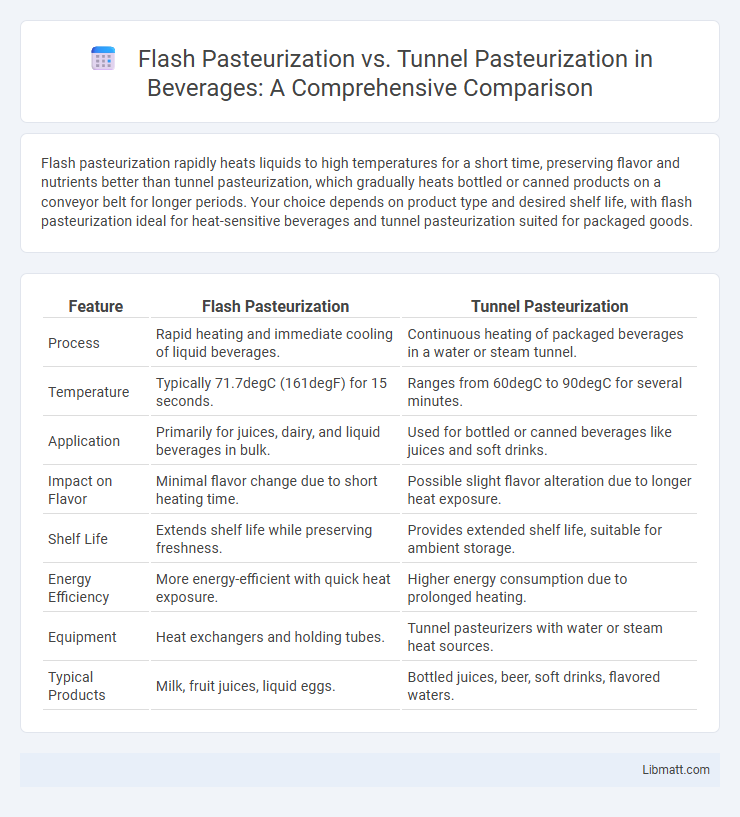

Flash pasteurization rapidly heats liquids to high temperatures for a short time, preserving flavor and nutrients better than tunnel pasteurization, which gradually heats bottled or canned products on a conveyor belt for longer periods. Your choice depends on product type and desired shelf life, with flash pasteurization ideal for heat-sensitive beverages and tunnel pasteurization suited for packaged goods.

Table of Comparison

| Feature | Flash Pasteurization | Tunnel Pasteurization |

|---|---|---|

| Process | Rapid heating and immediate cooling of liquid beverages. | Continuous heating of packaged beverages in a water or steam tunnel. |

| Temperature | Typically 71.7degC (161degF) for 15 seconds. | Ranges from 60degC to 90degC for several minutes. |

| Application | Primarily for juices, dairy, and liquid beverages in bulk. | Used for bottled or canned beverages like juices and soft drinks. |

| Impact on Flavor | Minimal flavor change due to short heating time. | Possible slight flavor alteration due to longer heat exposure. |

| Shelf Life | Extends shelf life while preserving freshness. | Provides extended shelf life, suitable for ambient storage. |

| Energy Efficiency | More energy-efficient with quick heat exposure. | Higher energy consumption due to prolonged heating. |

| Equipment | Heat exchangers and holding tubes. | Tunnel pasteurizers with water or steam heat sources. |

| Typical Products | Milk, fruit juices, liquid eggs. | Bottled juices, beer, soft drinks, flavored waters. |

Introduction to Pasteurization Methods

Flash pasteurization rapidly heats liquids to high temperatures (typically 71.5degC for 15-30 seconds) to kill harmful microorganisms while preserving flavor and nutrients. Tunnel pasteurization gradually heats packaged products through a controlled water bath or steam tunnel, ensuring thorough microbial reduction with minimal packaging damage. Choosing the right pasteurization method depends on your product's sensitivity, shelf-life requirements, and production scale.

What is Flash Pasteurization?

Flash pasteurization, also known as high-temperature short-time (HTST) pasteurization, involves rapidly heating a liquid to around 71.5degC (160degF) for 15 to 30 seconds before quickly cooling it to preserve flavor and nutritional quality. This method is commonly used in the beverage industry for products like fruit juices, milk, and liquid eggs, providing effective microbial control with minimal thermal damage. Flash pasteurization offers energy efficiency and maintains product freshness compared to traditional tunnel pasteurization, which uses longer heating times.

What is Tunnel Pasteurization?

Tunnel pasteurization is a continuous thermal process used primarily in the beverage and food packaging industries to eliminate microbial contamination and extend product shelf life. Products, typically sealed in bottles or cans, pass through a temperature-controlled water bath where they are gradually heated to a specific pasteurization temperature and then cooled. This method ensures uniform heat treatment, preserving flavor and nutritional quality while preventing spoilage and ensuring food safety.

Key Differences Between Flash and Tunnel Pasteurization

Flash pasteurization rapidly heats liquid products to high temperatures for a short time, preserving flavor and nutrients, while tunnel pasteurization slowly heats packaged products by passing them through a water bath. Flash pasteurization suits liquids like juices and milk, ensuring microbial safety with minimal thermal damage, whereas tunnel pasteurization is ideal for solid or bottled goods requiring uniform heat exposure. Your choice depends on product type, packaging, and desired shelf life, with flash offering efficiency and tunnel providing thorough, batch-consistent pasteurization.

Advantages of Flash Pasteurization

Flash pasteurization offers significant advantages over tunnel pasteurization, including shorter processing times that preserve the fresh flavor, color, and nutritional content of beverages. This method uses high temperatures for a brief period, enabling improved microbial safety with minimal thermal impact. Enhanced efficiency and energy savings also contribute to lower operational costs, making flash pasteurization ideal for heat-sensitive products like juices and dairy.

Advantages of Tunnel Pasteurization

Tunnel pasteurization offers precise temperature control, ensuring uniform heat distribution that effectively preserves product quality and extends shelf life. This method reduces risk of contamination by maintaining a continuous closed system, enhancing food safety for your products. Its compatibility with various packaging types, including glass, plastic, and cans, supports versatile production lines and higher throughput efficiency.

Application Areas: Flash vs Tunnel Pasteurization

Flash pasteurization is commonly applied in the beverage industry, especially for juices, milk, and liquid egg products requiring rapid heating and cooling to preserve flavor and nutrients. Tunnel pasteurization is predominantly used for packaged foods such as canned or bottled products, providing gradual and uniform heat treatment to extend shelf life. Your choice depends on the product form and processing speed, with flash suited for liquid products and tunnel for packaged goods.

Impact on Beverage Quality and Shelf Life

Flash pasteurization rapidly heats beverages to high temperatures for a short time, effectively preserving fresh flavor and nutritional content while extending shelf life. Tunnel pasteurization uses prolonged heating of bottled products, which can slightly alter taste and reduce some heat-sensitive nutrients but provides a longer shelf life. Both methods ensure microbial safety, with flash pasteurization favored for maintaining quality in delicate beverages and tunnel pasteurization suited for packaged products requiring extended storage.

Cost and Efficiency Comparison

Flash pasteurization offers higher efficiency by rapidly heating and cooling products in seconds, significantly reducing energy consumption and minimizing nutrient loss compared to tunnel pasteurization. Tunnel pasteurization, while involving longer processing times and higher energy use due to gradual heating, is often preferred for packaged goods requiring uniform treatment. Cost-wise, flash pasteurization incurs higher initial equipment expenses but lowers operational costs through faster throughput and reduced thermal damage, whereas tunnel pasteurization demands less upfront investment but results in increased ongoing energy and labor costs.

Choosing the Best Pasteurization Method for Your Process

Flash pasteurization uses high temperature for a short time, preserving flavor and nutrients, making it ideal for beverages like juices and dairy products. Tunnel pasteurization provides gradual heat over a longer period, suitable for packaged goods that require extended shelf life and sterilization, such as canned or bottled foods. Selecting the optimal pasteurization method depends on product type, packaging, desired shelf life, and quality retention requirements.

Flash pasteurization vs tunnel pasteurization Infographic

libmatt.com

libmatt.com