Spinning cone column technology enhances separation efficiency by using centrifugal force and low-temperature evaporation, preserving flavor and aroma compounds better than vacuum distillation. Your choice depends on whether you prioritize gentle processing for delicate products or need a versatile method capable of handling a wide range of temperatures and pressures.

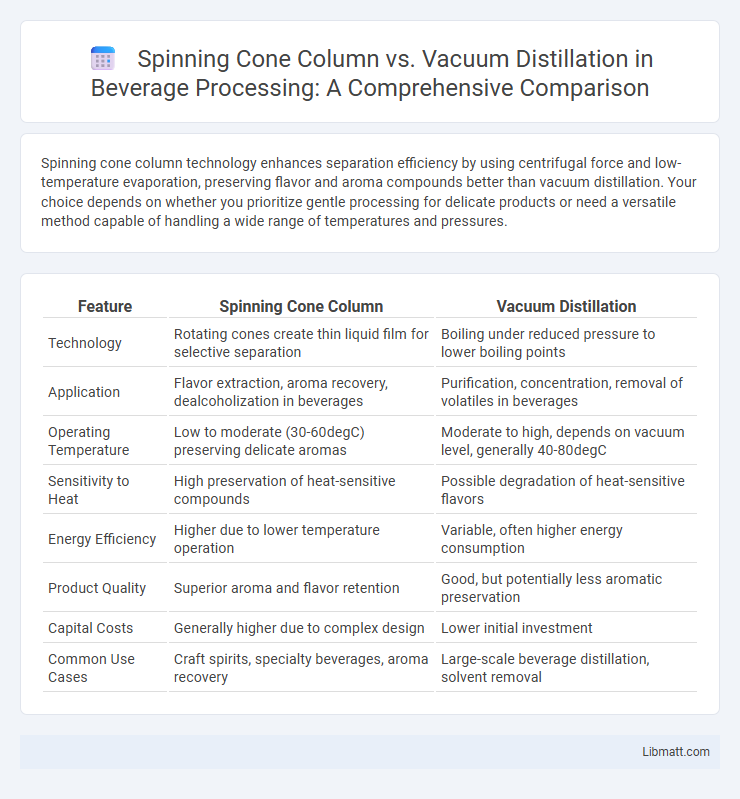

Table of Comparison

| Feature | Spinning Cone Column | Vacuum Distillation |

|---|---|---|

| Technology | Rotating cones create thin liquid film for selective separation | Boiling under reduced pressure to lower boiling points |

| Application | Flavor extraction, aroma recovery, dealcoholization in beverages | Purification, concentration, removal of volatiles in beverages |

| Operating Temperature | Low to moderate (30-60degC) preserving delicate aromas | Moderate to high, depends on vacuum level, generally 40-80degC |

| Sensitivity to Heat | High preservation of heat-sensitive compounds | Possible degradation of heat-sensitive flavors |

| Energy Efficiency | Higher due to lower temperature operation | Variable, often higher energy consumption |

| Product Quality | Superior aroma and flavor retention | Good, but potentially less aromatic preservation |

| Capital Costs | Generally higher due to complex design | Lower initial investment |

| Common Use Cases | Craft spirits, specialty beverages, aroma recovery | Large-scale beverage distillation, solvent removal |

Introduction to Spinning Cone Column and Vacuum Distillation

Spinning cone column technology employs centrifugal force and thin-film evaporation to separate volatile compounds at lower temperatures, preserving the quality of heat-sensitive liquids like wine and juice. Vacuum distillation reduces the boiling points of liquids by lowering the surrounding pressure, enabling efficient separation without thermal degradation. Your choice between these methods depends on the desired product quality, energy efficiency, and sensitivity to heat during the distillation process.

Principles of Operation

Spinning cone columns separate liquids based on volatility differences by using a rotating cone within a vacuum, enhancing mass transfer and allowing gentle separation at lower temperatures. Vacuum distillation lowers the boiling points of components by reducing pressure, enabling the separation of compounds without thermal degradation. You can choose the spinning cone column for heat-sensitive materials requiring precise volatile component removal, while vacuum distillation suits broader separation needs in low-pressure environments.

Key Differences Between the Two Technologies

Spinning cone column uses centrifugal force and low-pressure steam to separate volatile compounds at lower temperatures, preserving delicate flavors and aromas, whereas vacuum distillation operates by reducing pressure to lower boiling points for thermal-sensitive materials. Spinning cone columns offer faster processing and higher selectivity for aroma recovery, while vacuum distillation excels in separating mixtures with closer boiling points and higher purity requirements. Your choice depends on the desired product quality, processing time, and thermal sensitivity of the feedstock.

Applications in the Food and Beverage Industry

Spinning cone columns are widely used in the food and beverage industry for gentle aroma recovery and flavor enhancement, preserving volatile compounds during processes like flavor extraction and de-alcoholization. Vacuum distillation, by contrast, excels in separating heat-sensitive ingredients under reduced pressure, effectively concentrating flavors or removing impurities without degrading quality. Your choice between these technologies depends on the desired balance between aroma retention and process efficiency in products such as wines, spirits, and essential oils.

Efficiency and Energy Consumption

Spinning cone columns offer higher separation efficiency compared to vacuum distillation by utilizing thin film evaporation and multi-stage condensation, resulting in better preservation of heat-sensitive components. Energy consumption in spinning cone columns is generally lower due to shorter residence times and the ability to operate at lower temperatures, reducing thermal degradation and operational costs. Your choice between the two methods will depend on the specific application, but spinning cone columns typically provide more efficient and energy-saving solutions for complex separations.

Impact on Flavor and Aroma Retention

Spinning cone columns excel in preserving delicate flavor and aroma compounds due to their low-temperature, short-residence-time processing, minimizing thermal degradation. Vacuum distillation also reduces thermal impact by operating under reduced pressure, but longer exposure to heat may lead to greater volatility loss and flavor alteration. Consequently, spinning cone technology is preferred for high-quality product applications where maintaining the natural sensory profile is critical.

Scalability and Industrial Adaptation

Spinning cone columns offer superior scalability for processing heat-sensitive and high-value liquids, enabling precise flavor and aroma recovery in large-scale beverage and food production. Vacuum distillation excels in industrial adaptation by efficiently separating high-boiling point compounds under reduced pressure, ideal for chemical and pharmaceutical manufacturing. Your choice depends on the specific process requirements, with spinning cone columns favored for delicate separations and vacuum distillation suited for high-volume, thermal-sensitive operations.

Cost Considerations and Maintenance

Spinning cone columns generally incur higher initial costs due to advanced technology and more intricate design compared to vacuum distillation systems, which tend to be more economically accessible. Maintenance expenses for spinning cone columns are often elevated because of their complex rotating components requiring specialized servicing and regular calibration, whereas vacuum distillation units benefit from simpler mechanical parts and lower maintenance frequency. Cost optimization strategies must consider these differences, balancing capital investment against operational efficiency and downtime impacts.

Environmental and Safety Aspects

Spinning cone columns operate at lower temperatures and reduced pressure, minimizing thermal degradation and energy consumption, which significantly lowers the environmental impact compared to vacuum distillation. The vacuum distillation process requires extensive energy input to maintain high vacuum and temperature conditions, potentially increasing greenhouse gas emissions and operational hazards. Spinning cone technology also reduces the risk of solvent losses and exposure, enhancing workplace safety by limiting volatile organic compound emissions and fire hazards.

Choosing the Right Technology for Your Process

Spinning cone column and vacuum distillation offer distinct advantages for separating heat-sensitive compounds in food and beverage processing, with the spinning cone column excelling in gentle, low-temperature evaporation to preserve flavor and aroma. Vacuum distillation provides efficient separation by lowering boiling points through reduced pressure, making it ideal for high-purity recovery but potentially less effective with delicate substances. Selecting the right technology depends on the product's thermal sensitivity, desired purity levels, and process scalability to optimize yield and quality.

Spinning cone column vs vacuum distillation Infographic

libmatt.com

libmatt.com