Clean-in-Place (CIP) systems automate cleaning inside equipment without disassembly, ensuring efficient sanitation in food and pharmaceutical industries while minimizing downtime. Clean-out-of-Place (COP) requires manual removal of parts for cleaning, offering thorough cleaning flexibility for complex components but increasing labor and processing time.

Table of Comparison

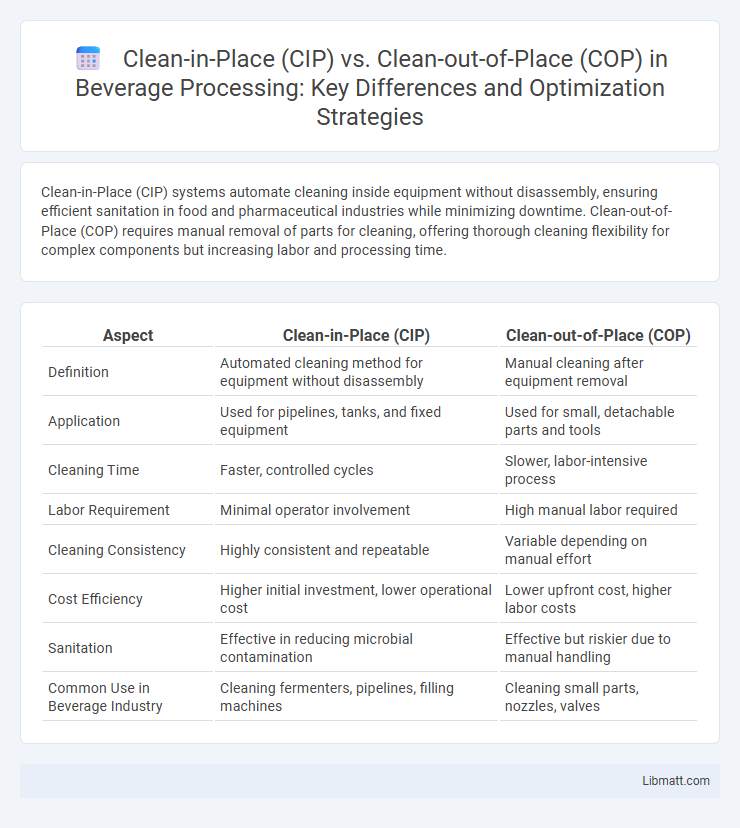

| Aspect | Clean-in-Place (CIP) | Clean-out-of-Place (COP) |

|---|---|---|

| Definition | Automated cleaning method for equipment without disassembly | Manual cleaning after equipment removal |

| Application | Used for pipelines, tanks, and fixed equipment | Used for small, detachable parts and tools |

| Cleaning Time | Faster, controlled cycles | Slower, labor-intensive process |

| Labor Requirement | Minimal operator involvement | High manual labor required |

| Cleaning Consistency | Highly consistent and repeatable | Variable depending on manual effort |

| Cost Efficiency | Higher initial investment, lower operational cost | Lower upfront cost, higher labor costs |

| Sanitation | Effective in reducing microbial contamination | Effective but riskier due to manual handling |

| Common Use in Beverage Industry | Cleaning fermenters, pipelines, filling machines | Cleaning small parts, nozzles, valves |

Introduction to CIP and COP Methods

Clean-in-Place (CIP) and Clean-out-of-Place (COP) are essential sanitation methods in industries such as food, beverage, and pharmaceuticals to ensure equipment hygiene. CIP involves automated cleaning of equipment without disassembly, making it efficient for large-scale continuous processes, while COP requires manual removal of components for thorough cleaning and inspection. Choosing between CIP and COP depends on your specific operational needs, equipment design, and cleanliness standards.

Defining Clean-in-Place (CIP)

Clean-in-Place (CIP) is an automated cleaning method used in food, pharmaceutical, and chemical industries to sanitize equipment without disassembly. CIP systems circulate cleaning solutions through pipes, tanks, and other closed equipment to remove residues and contaminants efficiently. This technique reduces downtime, minimizes manual labor, and ensures consistent hygiene standards in your production processes.

Understanding Clean-out-of-Place (COP)

Clean-out-of-Place (COP) refers to a cleaning process where equipment or components are removed from the production area for thorough cleaning, allowing for detailed inspection and maintenance. COP is essential for items that cannot be effectively cleaned in situ due to design complexity, material sensitivity, or contamination risk, ensuring compliance with hygiene standards in industries like pharmaceuticals and food processing. This method complements Clean-in-Place (CIP) by addressing cleaning challenges that CIP systems cannot handle, thus optimizing overall sanitation procedures.

Key Differences Between CIP and COP

Clean-in-Place (CIP) systems clean equipment without disassembly by circulating cleaning solutions through pipelines and surfaces, while Clean-out-of-Place (COP) involves removing equipment for manual cleaning. CIP offers higher efficiency and reduced contamination risk for fixed installations, whereas COP provides thorough cleaning for portable or complex parts that cannot be cleaned in situ. Your choice between CIP and COP depends on equipment design, cleaning requirements, and operational constraints.

Advantages of Clean-in-Place (CIP)

Clean-in-Place (CIP) systems offer significant advantages such as reducing downtime by enabling automated cleaning without disassembling equipment, which enhances operational efficiency. CIP systems improve hygiene control by ensuring consistent and repeatable cleaning cycles, minimizing contamination risks in food, beverage, and pharmaceutical industries. These systems also optimize water and chemical usage, leading to cost savings and environmental sustainability.

Benefits of Clean-out-of-Place (COP)

Clean-out-of-Place (COP) systems offer enhanced flexibility and thorough cleaning by allowing equipment to be disassembled and cleaned separately, ensuring better access to hard-to-reach areas. COP reduces the risk of cross-contamination by fully isolating components during the cleaning process, making it ideal for industries with stringent hygiene standards like pharmaceuticals and food production. Additionally, COP can extend the lifespan of sensitive equipment since parts are cleaned gently outside the main production line, minimizing exposure to harsh cleaning chemicals and mechanical wear.

Application Areas for CIP and COP

Clean-in-Place (CIP) systems are primarily used in industries requiring frequent cleaning of fixed equipment without disassembly, such as food and beverage processing, pharmaceuticals, and dairy production. Clean-out-of-Place (COP) applies to removable equipment and components, making it ideal for smaller parts in laboratories, medical devices, and manufacturing environments where thorough manual cleaning is necessary. Your choice between CIP and COP depends on the equipment design and the specific hygiene standards of your application area.

Factors to Consider When Choosing a Cleaning Method

When choosing between Clean-in-Place (CIP) and Clean-out-of-Place (COP) cleaning methods, factors such as equipment design, cleaning frequency, and contamination risk must be evaluated. CIP is ideal for complex systems requiring frequent sanitation without disassembly, reducing downtime and labor costs. Your decision should also consider sanitation validation requirements, chemical use, and the potential impact on product quality to ensure effective microbial control and compliance.

Cost and Efficiency Comparison: CIP vs COP

Clean-in-Place (CIP) systems generally offer higher efficiency by automating cleaning processes, reducing labor costs, and minimizing downtime in production lines, which leads to long-term savings despite higher initial investment. Clean-out-of-Place (COP) requires manual disassembly and cleaning of components, increasing labor and operational costs, but offers flexibility for smaller operations and lower upfront expenses. Your choice between CIP and COP should consider the scale of production, frequency of cleaning, and overall cost-effectiveness in your specific facility.

Future Trends in Industrial Cleaning Solutions

Future trends in industrial cleaning solutions emphasize automation and sustainability, with Clean-in-Place (CIP) systems evolving to incorporate real-time monitoring and data analytics for enhanced process control and reduced resource consumption. Clean-out-of-Place (COP) methods are integrating advanced robotics and smart sensors to improve efficiency and minimize human contact in hazardous environments. Both CIP and COP technologies are advancing towards eco-friendly cleaning agents and energy-efficient operations, aligning with industry demands for cleaner production and regulatory compliance.

Clean-in-Place (CIP) vs Clean-out-of-Place (COP) Infographic

libmatt.com

libmatt.com