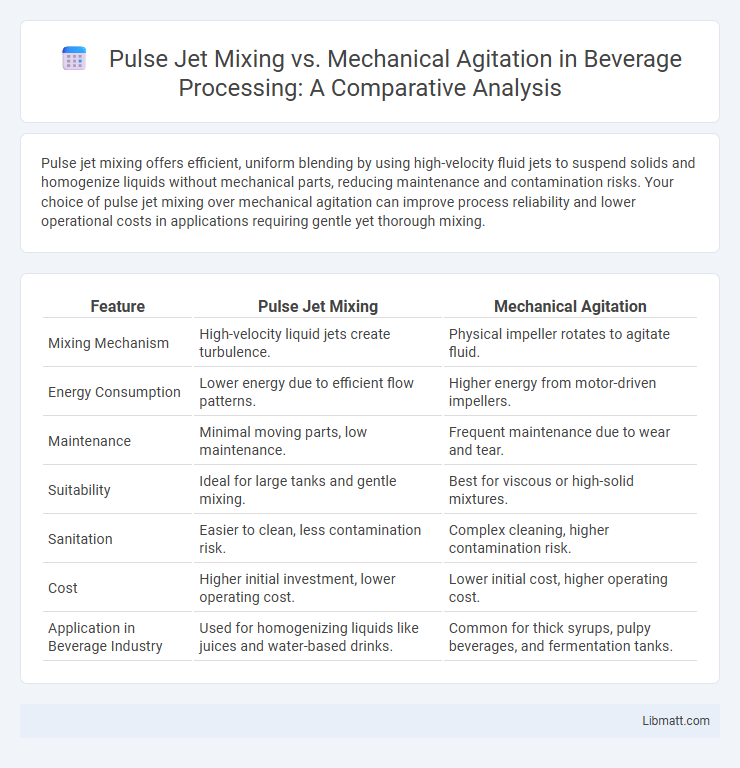

Pulse jet mixing offers efficient, uniform blending by using high-velocity fluid jets to suspend solids and homogenize liquids without mechanical parts, reducing maintenance and contamination risks. Your choice of pulse jet mixing over mechanical agitation can improve process reliability and lower operational costs in applications requiring gentle yet thorough mixing.

Table of Comparison

| Feature | Pulse Jet Mixing | Mechanical Agitation |

|---|---|---|

| Mixing Mechanism | High-velocity liquid jets create turbulence. | Physical impeller rotates to agitate fluid. |

| Energy Consumption | Lower energy due to efficient flow patterns. | Higher energy from motor-driven impellers. |

| Maintenance | Minimal moving parts, low maintenance. | Frequent maintenance due to wear and tear. |

| Suitability | Ideal for large tanks and gentle mixing. | Best for viscous or high-solid mixtures. |

| Sanitation | Easier to clean, less contamination risk. | Complex cleaning, higher contamination risk. |

| Cost | Higher initial investment, lower operating cost. | Lower initial cost, higher operating cost. |

| Application in Beverage Industry | Used for homogenizing liquids like juices and water-based drinks. | Common for thick syrups, pulpy beverages, and fermentation tanks. |

Introduction to Mixing Technologies

Pulse jet mixing employs high-velocity jets of fluid to induce consistent suspension and blending within tanks, enhancing particle suspension without moving parts. Mechanical agitation relies on impellers or agitators, creating turbulence and shear forces to mix components, often requiring maintenance due to rotating equipment. Pulse jet systems offer improved reliability and reduced contamination risk compared to mechanical agitators in applications with sensitive or hazardous materials.

Overview of Pulse Jet Mixing

Pulse jet mixing utilizes high-velocity gas pulses to generate turbulence, promoting efficient suspension of solids in liquids without mechanical moving parts. This method reduces maintenance requirements and minimizes contamination risks compared to mechanical agitation, which relies on rotating impellers. Pulse jet mixers are particularly effective in radioactive waste treatment and large-scale industrial tanks due to their robust, non-intrusive design and energy efficiency.

Fundamentals of Mechanical Agitation

Mechanical agitation relies on rotational motion using impellers or paddles to induce fluid flow and enhance mixing efficiency by creating shear and turbulence within the vessel. It operates based on principles of fluid dynamics, where torque applied to the impeller shaft is converted into kinetic energy, promoting homogeneous blending of materials. This method is widely used in industries requiring precise control over mixing speed, shear rate, and energy input to achieve uniform dispersion and avoid phase separation.

Key Operational Differences

Pulse jet mixing uses high-velocity fluid pulses to create turbulent flow, eliminating moving parts and reducing maintenance, whereas mechanical agitation relies on rotating impellers to physically stir the liquid. Mechanical agitators provide direct shear forces and are effective in blending viscous materials, while pulse jet mixers offer uniform mixing and improved solids suspension with lower energy consumption. You can choose pulse jet mixing for systems requiring minimal downtime and enhanced homogenization, whereas mechanical agitation suits applications needing precise shear control.

Energy Efficiency Comparison

Pulse jet mixing consumes significantly less energy compared to mechanical agitation by utilizing compressed air pulses to induce fluid motion, reducing the need for continuous motor-driven operation. Mechanical agitation relies on rotating impellers that require constant high power, leading to higher energy consumption and operational costs. Studies indicate pulse jet systems can achieve up to 40-60% energy savings in industrial mixing applications due to intermittent rather than continuous energy input.

Mixing Effectiveness and Homogeneity

Pulse jet mixing enhances mixing effectiveness and homogeneity by creating high-velocity jets that induce thorough fluid movement and minimize dead zones, resulting in uniform suspension of solids and improved mass transfer. Mechanical agitation relies on impellers to generate shear and turbulence, which can cause uneven mixing and may leave localized gradients or stagnant areas, especially in large tanks. For your process, pulse jet mixing often delivers superior homogeneity and consistent mixing performance, particularly in applications with high solid concentrations or sensitive materials.

Maintenance and Equipment Longevity

Pulse jet mixing systems reduce maintenance needs due to fewer moving parts and less mechanical wear compared to mechanical agitators, which require regular inspection and replacement of bearings, seals, and impellers. The absence of submerged rotating components in pulse jet mixers minimizes equipment failure and extends operational life, enhancing overall process reliability. Mechanical agitators, prone to corrosion and fatigue from constant motion, generally have shorter equipment longevity and higher maintenance costs over time.

Applications in Industry

Pulse jet mixing offers superior efficiency in handling highly viscous or non-Newtonian fluids, making it ideal for industries like chemical processing, wastewater treatment, and food production. Mechanical agitation remains prevalent in pharmaceutical manufacturing and conventional mixing tasks due to its reliable shear control and adaptability to various tank sizes. The selection between pulse jet mixing and mechanical agitation depends on specific application requirements such as fluid properties, energy consumption, and contamination risks.

Cost Considerations

Pulse jet mixing generally offers lower operational and maintenance costs compared to mechanical agitation due to fewer moving parts and reduced energy consumption. Mechanical agitators often require frequent repairs and higher energy input, especially in large-scale applications, increasing overall expenses. You can optimize budget efficiency by selecting pulse jet systems for processes demanding continuous, robust mixing with minimal downtime.

Selecting the Right Mixing Technique

Pulse jet mixing offers superior efficiency for large-scale industrial tanks by generating high-velocity fluid pulses that minimize energy consumption and reduce maintenance compared to mechanical agitation. Mechanical agitation suits applications requiring precise shear control and is effective in smaller volumes with viscous or shear-sensitive fluids. Choosing the right mixing technique depends on factors such as tank size, fluid properties, energy efficiency, and maintenance requirements to optimize process performance.

Pulse jet mixing vs mechanical agitation Infographic

libmatt.com

libmatt.com