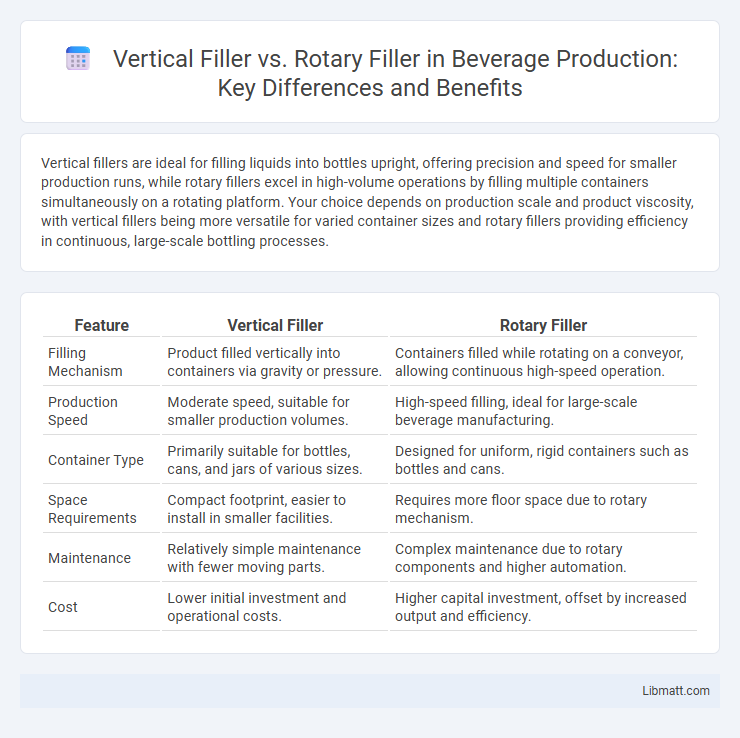

Vertical fillers are ideal for filling liquids into bottles upright, offering precision and speed for smaller production runs, while rotary fillers excel in high-volume operations by filling multiple containers simultaneously on a rotating platform. Your choice depends on production scale and product viscosity, with vertical fillers being more versatile for varied container sizes and rotary fillers providing efficiency in continuous, large-scale bottling processes.

Table of Comparison

| Feature | Vertical Filler | Rotary Filler |

|---|---|---|

| Filling Mechanism | Product filled vertically into containers via gravity or pressure. | Containers filled while rotating on a conveyor, allowing continuous high-speed operation. |

| Production Speed | Moderate speed, suitable for smaller production volumes. | High-speed filling, ideal for large-scale beverage manufacturing. |

| Container Type | Primarily suitable for bottles, cans, and jars of various sizes. | Designed for uniform, rigid containers such as bottles and cans. |

| Space Requirements | Compact footprint, easier to install in smaller facilities. | Requires more floor space due to rotary mechanism. |

| Maintenance | Relatively simple maintenance with fewer moving parts. | Complex maintenance due to rotary components and higher automation. |

| Cost | Lower initial investment and operational costs. | Higher capital investment, offset by increased output and efficiency. |

Introduction to Vertical and Rotary Fillers

Vertical fillers handle liquid and semi-liquid products using a vertical piston or pump system, ideal for filling bottles or containers with precise volumes. Rotary fillers operate with a rotating turret that moves containers through filling stations, offering high-speed accuracy for large-scale production lines. Your choice depends on production speed, container type, and product viscosity for optimal packaging efficiency.

How Vertical Fillers Work

Vertical fillers operate by filling containers in an upright position using gravity and controlled flow mechanisms, ideal for filling liquids, powders, and granules with precision. These machines use a vertical piston or pump system to dispense a measured volume into each container, ensuring consistent fill levels and minimizing spillage. Your production efficiency benefits from the vertical filler's adaptability to different container shapes and sizes, making it a versatile choice for various packaging lines.

How Rotary Fillers Operate

Rotary fillers operate using a continuously rotating turret equipped with multiple filling heads that simultaneously dispense product into containers as they move along a conveyor. The filling process is synchronized with the turret's rotation, enabling high-speed and precise volumetric or gravimetric filling in industries such as pharmaceuticals, food, and cosmetics. This design minimizes product spillage and ensures consistent fill levels across large production volumes.

Key Differences Between Vertical and Rotary Fillers

Vertical fillers use a vertical piston or gravity to fill containers individually, making them ideal for small to medium production volumes and varying container sizes. Rotary fillers operate with a rotating carousel that fills multiple containers simultaneously, providing high-speed, consistent filling for large-scale production lines. Key differences include speed, container compatibility, and scalability, with vertical fillers offering flexibility and rotary fillers maximizing throughput.

Applications of Vertical Fillers

Vertical fillers are widely used in industries such as pharmaceuticals, cosmetics, and food processing for accurately filling powders, granules, and small-sized products into containers. Their compact design and flexibility make them ideal for packaging products like tablets, capsules, and granular food items in bottles, jars, and sachets. Compared to rotary fillers, vertical fillers excel in handling low to medium production volumes with precise dosing capabilities and easy changeover between product types.

Applications of Rotary Fillers

Rotary fillers are widely used in high-speed production lines for packaging liquids, creams, and viscous products in industries like food and beverage, pharmaceuticals, and cosmetics. These fillers excel in applications requiring precise volume control and rapid output, such as filling bottles, jars, and containers with products like sauces, lotions, and syrups. Your choice of a rotary filler enhances efficiency in large-scale operations where consistent fill accuracy and throughput are critical.

Efficiency and Speed Comparison

Vertical fillers typically offer higher speeds for low to medium viscosity products due to faster filling cycles and easier machine access for maintenance, resulting in increased production efficiency. Rotary fillers excel in handling high volumes with consistency by simultaneously filling multiple containers, making them ideal for large-scale operations demanding precision and reduced downtime. Your choice should consider product type, production volume, and desired output rate to optimize efficiency and speed in your filling process.

Cost Considerations: Vertical vs Rotary Fillers

Vertical fillers generally have lower initial costs and are more suitable for small to medium production volumes, offering easier maintenance and less complex machinery. Rotary fillers, although involving higher upfront investment, provide greater efficiency and speed for large-scale production lines, reducing per-unit costs over time. Selecting between vertical and rotary fillers depends on budget constraints, production volume, and long-term operational expenses.

Maintenance and Durability Factors

Vertical fillers typically feature simpler designs with fewer moving parts, leading to easier maintenance and lower downtime compared to rotary fillers, which are more complex and require specialized attention. The durability of rotary fillers is often higher due to robust construction suited for high-speed production, but this comes with increased maintenance demands to sustain optimal performance. Selecting between the two depends on balancing maintenance capabilities with production speed needs in packaging operations.

Choosing the Right Filler for Your Production Line

Vertical fillers excel in handling thick and viscous products with precision, making them ideal for industries like food, pharmaceuticals, and cosmetics. Rotary fillers provide high-speed, continuous filling suitable for large-scale production, ensuring efficiency and minimal downtime. Selecting the right filler depends on your product's viscosity, production volume, and desired speed to optimize your packaging line performance.

Vertical filler vs rotary filler Infographic

libmatt.com

libmatt.com