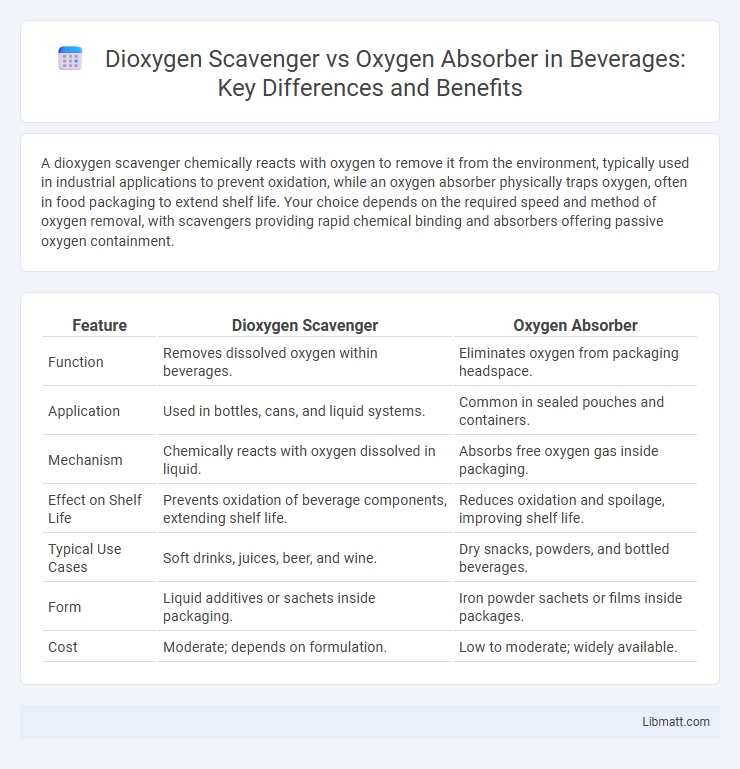

A dioxygen scavenger chemically reacts with oxygen to remove it from the environment, typically used in industrial applications to prevent oxidation, while an oxygen absorber physically traps oxygen, often in food packaging to extend shelf life. Your choice depends on the required speed and method of oxygen removal, with scavengers providing rapid chemical binding and absorbers offering passive oxygen containment.

Table of Comparison

| Feature | Dioxygen Scavenger | Oxygen Absorber |

|---|---|---|

| Function | Removes dissolved oxygen within beverages. | Eliminates oxygen from packaging headspace. |

| Application | Used in bottles, cans, and liquid systems. | Common in sealed pouches and containers. |

| Mechanism | Chemically reacts with oxygen dissolved in liquid. | Absorbs free oxygen gas inside packaging. |

| Effect on Shelf Life | Prevents oxidation of beverage components, extending shelf life. | Reduces oxidation and spoilage, improving shelf life. |

| Typical Use Cases | Soft drinks, juices, beer, and wine. | Dry snacks, powders, and bottled beverages. |

| Form | Liquid additives or sachets inside packaging. | Iron powder sachets or films inside packages. |

| Cost | Moderate; depends on formulation. | Low to moderate; widely available. |

Introduction to Dioxygen Scavengers and Oxygen Absorbers

Dioxygen scavengers are chemical compounds designed to selectively remove oxygen from various environments, protecting products from oxidation and spoilage. Oxygen absorbers function similarly by actively absorbing oxygen within sealed packaging to extend shelf life and maintain product quality. Understanding the difference helps you choose the optimal solution for preserving sensitive goods and ensuring safety.

Chemical Mechanisms: Dioxygen Scavengers vs Oxygen Absorbers

Dioxygen scavengers chemically react with oxygen molecules, typically through oxidation reactions using compounds like iron powder or ascorbic acid, to remove dioxygen (O2) from the environment. Oxygen absorbers often incorporate these scavenger materials but are designed to absorb and reduce oxygen levels through a combination of physical absorption and chemical reaction, ensuring enhanced preservation in packaging. Your choice between the two depends on the specific application and the desired efficiency of oxygen removal.

Key Differences in Functionality

Dioxygen scavengers chemically react with oxygen to remove it from environments by converting O2 into non-reactive compounds, effectively preventing oxidation and spoilage in sealed packages. Oxygen absorbers, typically containing iron powder, physically absorb oxygen by oxidizing the iron, reducing oxygen levels inside containers to extend shelf life and maintain product freshness. The main functional distinction lies in dioxygen scavengers' chemical transformation of oxygen versus oxygen absorbers' reliance on oxidation of embedded materials to achieve deoxygenation.

Common Applications in Various Industries

Dioxygen scavengers are widely utilized in pharmaceutical packaging to prolong shelf life by preventing oxidation of sensitive drugs, while oxygen absorbers find extensive application in food packaging to inhibit spoilage and maintain freshness. In the electronics industry, dioxygen scavengers protect components from corrosion caused by oxygen exposure, whereas oxygen absorbers are employed in metal packaging to prevent rust formation. Both technologies play crucial roles in preserving product integrity across sectors such as chemicals, electronics, pharmaceuticals, and food processing.

Benefits of Using Dioxygen Scavengers

Dioxygen scavengers effectively remove molecular oxygen from packaging environments, significantly extending the shelf life of oxygen-sensitive products by preventing oxidation and spoilage. They offer precise oxygen control without altering humidity levels, making them ideal for pharmaceuticals, food, and electronics preservation. Using dioxygen scavengers reduces the risk of microbial growth and maintains product quality, ensuring safety and consumer satisfaction.

Advantages of Oxygen Absorbers

Oxygen absorbers provide efficient and reliable removal of oxygen from sealed environments, enhancing shelf life and preserving product quality. Their ability to maintain low oxygen levels prevents spoilage, oxidation, and microbial growth without affecting the packaged item. By using oxygen absorbers, you ensure improved freshness, color retention, and extended storage time for food, pharmaceuticals, and sensitive electronics.

Safety and Regulatory Considerations

Dioxygen scavengers typically contain chemical compounds such as iron powder or ascorbic acid, which must comply with food-grade safety standards set by regulatory bodies like the FDA and EFSA to ensure non-toxicity in packaging applications. Oxygen absorbers, often used in modified atmosphere packaging, require strict verification of material safety data sheets (MSDS) and adherence to international regulations including ISO 22000 and HACCP to avoid contamination and ensure consumer protection. Both technologies demand thorough risk assessments and clear labeling to meet industry standards and maintain product integrity throughout shelf life.

Selection Criteria: Choosing the Right Solution

Selection criteria for dioxygen scavengers versus oxygen absorbers depend on factors such as the target oxygen concentration, packaging type, and product sensitivity. Dioxygen scavengers chemically react with oxygen, making them ideal for low-oxygen environments or products requiring extended shelf life. Oxygen absorbers physically adsorb oxygen, offering a cost-effective solution for perishable goods with moderate oxygen sensitivity.

Environmental Impact and Sustainability

Dioxygen scavengers primarily rely on chemical reactions to remove oxygen, often producing minimal waste and making them more environmentally friendly compared to some oxygen absorbers that may contain iron powder or other metals with higher disposal concerns. Oxygen absorbers typically generate solid residues that require proper waste management to prevent soil and water contamination, impacting their sustainability profile negatively. The choice between the two affects packaging sustainability, where dioxygen scavengers support longer shelf life with lower ecological footprints, aligning better with eco-friendly initiatives.

Future Trends in Oxygen Removal Technologies

Future trends in oxygen removal technologies emphasize advancements in dioxygen scavengers and oxygen absorbers to enhance food preservation and industrial processes. Innovations focus on developing eco-friendly, non-toxic materials with higher efficiency and longer activity duration to minimize oxygen-related degradation. Integration of smart packaging systems with real-time oxygen monitoring and controlled oxygen scavenging is expected to redefine preservation capabilities in various sectors.

Dioxygen scavenger vs oxygen absorber Infographic

libmatt.com

libmatt.com