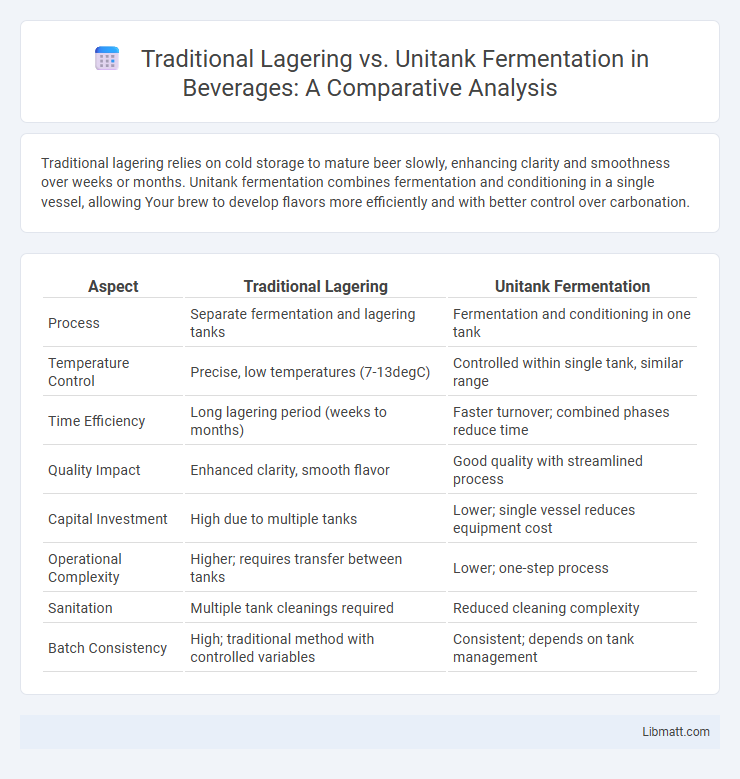

Traditional lagering relies on cold storage to mature beer slowly, enhancing clarity and smoothness over weeks or months. Unitank fermentation combines fermentation and conditioning in a single vessel, allowing Your brew to develop flavors more efficiently and with better control over carbonation.

Table of Comparison

| Aspect | Traditional Lagering | Unitank Fermentation |

|---|---|---|

| Process | Separate fermentation and lagering tanks | Fermentation and conditioning in one tank |

| Temperature Control | Precise, low temperatures (7-13degC) | Controlled within single tank, similar range |

| Time Efficiency | Long lagering period (weeks to months) | Faster turnover; combined phases reduce time |

| Quality Impact | Enhanced clarity, smooth flavor | Good quality with streamlined process |

| Capital Investment | High due to multiple tanks | Lower; single vessel reduces equipment cost |

| Operational Complexity | Higher; requires transfer between tanks | Lower; one-step process |

| Sanitation | Multiple tank cleanings required | Reduced cleaning complexity |

| Batch Consistency | High; traditional method with controlled variables | Consistent; depends on tank management |

Introduction to Beer Fermentation Methods

Traditional lagering utilizes cold fermentation followed by extended aging at low temperatures, which enhances clarity and smoothness in your beer. Unitank fermentation combines fermentation and conditioning in a single vessel, streamlining production and improving flavor consistency. Each method impacts the beer's taste profile and production timeline, influencing your brewing choices.

What is Traditional Lagering?

Traditional lagering is a cold conditioning process where beer is stored at near-freezing temperatures for several weeks to months, allowing flavors to mature and unwanted compounds to settle. This method enhances clarity, smoothness, and crispness in the final beer by promoting slow fermentation and natural carbonation. Your brew benefits from reduced off-flavors and a clean, refined profile thanks to this extended cold storage phase.

Understanding Unitank Fermentation

Unitank fermentation combines fermentation and conditioning in a single vessel, streamlining the brewing process by eliminating the need for separate lagering tanks. Unlike traditional lagering, which requires extended cold storage to mature beer, unitanks maintain precise temperature control to develop flavors efficiently while preserving carbonation. Your brewery can benefit from this method by reducing space requirements and accelerating production cycles without compromising beer quality.

Key Differences Between Lagering and Unitank Approaches

Traditional lagering involves conditioning beer at low temperatures for extended periods, enhancing clarity and smoothness through slow maturation in cold storage. Unitank fermentation combines fermentation and conditioning in a single vessel with controlled temperature zones, allowing precise management and faster production cycles. The key differences lie in temperature control, fermentation duration, and vessel utilization, with lagering emphasizing prolonged cold storage and unitanks offering efficiency through integrated processes.

Impact on Beer Flavor and Quality

Traditional lagering, characterized by extended cold storage, enhances beer flavor by promoting clarity, smoothness, and balanced malt profiles through slow yeast sedimentation and reduction of diacetyl and sulfur compounds. Unitank fermentation integrates fermentation and maturation in a single vessel, offering controlled temperature conditions that preserve fresh hop aromas and subtle ester profiles, resulting in a beer with vibrant flavor and consistent quality. The choice between these processes significantly influences the final beer's sensory attributes, with lagering favoring a cleaner, well-rounded taste, while unitank fermentation emphasizes freshness and aromatic complexity.

Time and Efficiency Considerations

Traditional lagering requires extended cold storage periods ranging from several weeks to months to develop clean and crisp flavor profiles, significantly increasing production time and storage costs. Unitank fermentation combines primary fermentation and maturation within a single vessel, reducing overall brewing time by eliminating the need for transfer and separate lagering phases. This method enhances operational efficiency and accelerates turnarounds, ideal for breweries aiming to optimize production schedules without compromising beer quality.

Equipment and Space Requirements

Traditional lagering requires large, temperature-controlled lagering tanks and dedicated cold storage rooms, demanding significant space for extended maturation periods. Unitank fermentation, combining fermentation and conditioning in one vessel, optimizes brewery footprint by reducing the number of tanks needed, thus saving valuable floor space. Your choice of equipment affects scalability, with unitanks offering streamlined operations while traditional lagering involves more specialized and bulky infrastructure.

Cost Implications for Breweries

Traditional lagering requires extended cold storage times, increasing refrigeration energy costs and tying up valuable tank capacity, which can raise overall production expenses for breweries. Unitank fermentation consolidates fermentation and conditioning processes in a single vessel, reducing the need for additional tanks and shortening production cycles, thereby lowering capital and operational costs. Brewers can optimize cash flow and reduce space requirements by adopting unitank systems, although initial investment in specialized tanks may be higher.

Popularity Trends in Modern Brewing

Traditional lagering remains a favored method among craft brewers seeking classic, clean flavors due to its extended cold maturation process, which enhances clarity and smoothness. In contrast, unitank fermentation gains popularity for its efficiency, enabling simultaneous fermentation and maturation in a single vessel, reducing production time and costs. Your brewery can benefit from unitank setups when targeting fast turnaround without sacrificing the quality associated with traditional lager profiles.

Which Method is Best for Your Brewery?

Traditional lagering offers precise temperature control and extended maturation, producing smooth, clean flavors ideal for classic beers. Unitank fermentation combines fermenting and conditioning in one vessel, reducing equipment costs and speeding up production cycles without compromising quality. Your choice depends on balancing desired beer characteristics, production capacity, and investment in brewing infrastructure.

Traditional lagering vs unitank fermentation Infographic

libmatt.com

libmatt.com