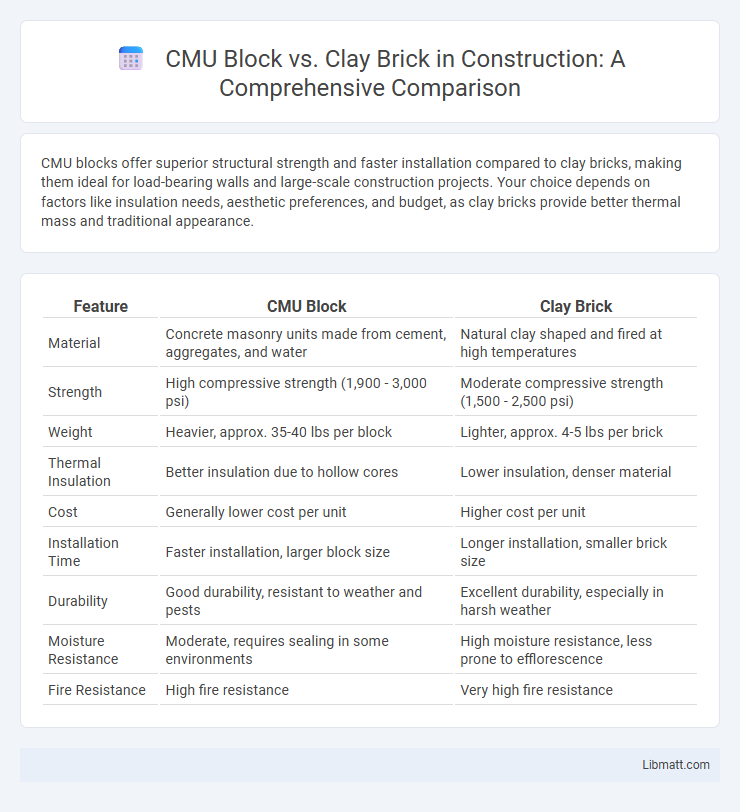

CMU blocks offer superior structural strength and faster installation compared to clay bricks, making them ideal for load-bearing walls and large-scale construction projects. Your choice depends on factors like insulation needs, aesthetic preferences, and budget, as clay bricks provide better thermal mass and traditional appearance.

Table of Comparison

| Feature | CMU Block | Clay Brick |

|---|---|---|

| Material | Concrete masonry units made from cement, aggregates, and water | Natural clay shaped and fired at high temperatures |

| Strength | High compressive strength (1,900 - 3,000 psi) | Moderate compressive strength (1,500 - 2,500 psi) |

| Weight | Heavier, approx. 35-40 lbs per block | Lighter, approx. 4-5 lbs per brick |

| Thermal Insulation | Better insulation due to hollow cores | Lower insulation, denser material |

| Cost | Generally lower cost per unit | Higher cost per unit |

| Installation Time | Faster installation, larger block size | Longer installation, smaller brick size |

| Durability | Good durability, resistant to weather and pests | Excellent durability, especially in harsh weather |

| Moisture Resistance | Moderate, requires sealing in some environments | High moisture resistance, less prone to efflorescence |

| Fire Resistance | High fire resistance | Very high fire resistance |

Introduction to CMU Block and Clay Brick

CMU blocks, or concrete masonry units, are manufactured from concrete and aggregates, offering high compressive strength and excellent durability for building applications. Clay bricks are fired clay units known for their natural thermal insulation, aesthetic appeal, and long-lasting weather resistance. Both materials are fundamental in construction, with CMU blocks favored for structural efficiency and cost-effectiveness, while clay bricks are preferred for their classic appearance and superior thermal properties.

Composition and Manufacturing Process

CMU blocks are primarily composed of cement, water, and aggregates such as sand or gravel, produced through a molding and curing process that involves hydraulic pressing or vibration to enhance density and strength. In contrast, clay bricks are made from natural clay materials, shaped through extrusion or hand-molding, then fired at high temperatures in kilns to achieve hardness and durability. The manufacturing process of CMU blocks is typically faster and allows for larger unit sizes compared to the traditional firing process required for clay bricks.

Physical Properties and Strength

CMU blocks typically have lower density and porosity compared to clay bricks, resulting in improved thermal insulation and reduced water absorption. In terms of strength, CMU blocks exhibit a compressive strength range of 1,500 to 3,000 psi, while clay bricks often achieve higher compressive strength between 3,000 and 5,000 psi. The physical properties of CMU blocks make them suitable for large-scale construction with faster assembly, whereas clay bricks offer superior durability and resistance to weathering.

Thermal Insulation and Energy Efficiency

CMU blocks offer moderate thermal insulation but typically have higher thermal conductivity than clay bricks, resulting in greater heat transfer and less energy efficiency in building envelopes. Clay bricks possess better thermal mass, absorbing and slowly releasing heat, which helps maintain balanced indoor temperatures and reduces heating and cooling demands. Incorporating insulation materials with CMUs enhances energy efficiency, yet clay bricks remain a preferred choice for passive thermal regulation in construction.

Cost Comparison and Affordability

CMU blocks generally offer a more cost-effective solution compared to clay bricks due to lower material and labor expenses. Clay bricks tend to be pricier because of their manufacturing process and installation time, impacting your overall construction budget. Evaluating your project's scale and long-term maintenance needs can help determine the most affordable option for durable building materials.

Durability and Lifespan

CMU blocks offer superior durability due to their density and resistance to weathering, often lasting over 50 years with minimal maintenance. Clay bricks also provide excellent lifespan, typically exceeding 75 years, benefiting from natural fire resistance and low water absorption. Your choice between CMU blocks and clay bricks depends on specific project requirements related to environmental exposure and structural demands.

Environmental Impact and Sustainability

CMU blocks have a lower environmental impact than traditional clay bricks due to their use of industrial by-products and reduced energy consumption during manufacturing. Clay bricks require high-temperature kilns that release significant CO2 emissions, while CMU blocks often incorporate recycled materials, enhancing sustainability. Furthermore, CMU blocks offer better thermal insulation, reducing energy needs for heating and cooling in buildings, thereby promoting eco-friendly construction practices.

Construction Speed and Ease of Installation

CMU blocks offer faster construction speed compared to clay bricks due to their larger size and uniform shape, reducing the number of units needed and allowing quicker laying. The ease of installation of CMU blocks is enhanced by their modular design and lighter weight, which simplifies handling and alignment. In contrast, clay bricks require more precise mortar application and more units per wall area, resulting in longer installation times.

Aesthetic Qualities and Design Flexibility

CMU blocks offer a utilitarian aesthetic with a more industrial look, commonly used in structural applications where functionality takes precedence over design intricacy. Clay bricks provide a warm, timeless appearance with rich color variations and intricate textures, enhancing architectural detail and curb appeal. Your design freedom expands with clay bricks due to their smaller size and variety of finishes, allowing for complex patterns and creative masonry work not easily achieved with CMU blocks.

Choosing the Right Material for Your Project

CMU blocks offer superior structural strength and fire resistance compared to traditional clay bricks, making them ideal for load-bearing walls and large-scale construction projects. Clay bricks excel in aesthetic appeal and thermal insulation, which suits residential or decorative applications where visual texture and energy efficiency are priorities. Evaluating project requirements such as durability, cost, insulation, and design preferences ensures the right material choice between CMU blocks and clay bricks for optimal performance and longevity.

CMU block vs clay brick Infographic

libmatt.com

libmatt.com