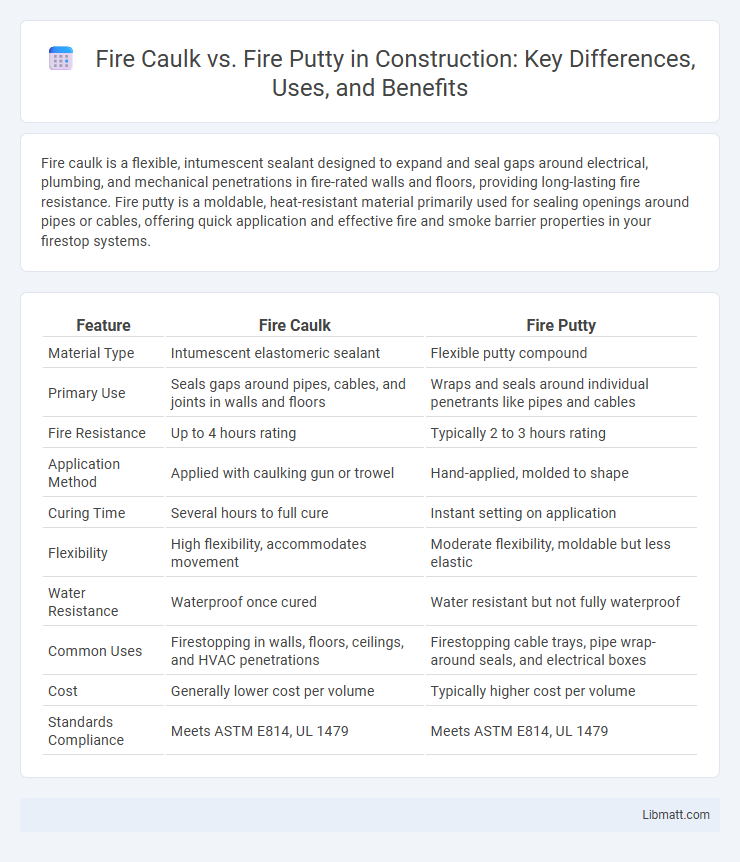

Fire caulk is a flexible, intumescent sealant designed to expand and seal gaps around electrical, plumbing, and mechanical penetrations in fire-rated walls and floors, providing long-lasting fire resistance. Fire putty is a moldable, heat-resistant material primarily used for sealing openings around pipes or cables, offering quick application and effective fire and smoke barrier properties in your firestop systems.

Table of Comparison

| Feature | Fire Caulk | Fire Putty |

|---|---|---|

| Material Type | Intumescent elastomeric sealant | Flexible putty compound |

| Primary Use | Seals gaps around pipes, cables, and joints in walls and floors | Wraps and seals around individual penetrants like pipes and cables |

| Fire Resistance | Up to 4 hours rating | Typically 2 to 3 hours rating |

| Application Method | Applied with caulking gun or trowel | Hand-applied, molded to shape |

| Curing Time | Several hours to full cure | Instant setting on application |

| Flexibility | High flexibility, accommodates movement | Moderate flexibility, moldable but less elastic |

| Water Resistance | Waterproof once cured | Water resistant but not fully waterproof |

| Common Uses | Firestopping in walls, floors, ceilings, and HVAC penetrations | Firestopping cable trays, pipe wrap-around seals, and electrical boxes |

| Cost | Generally lower cost per volume | Typically higher cost per volume |

| Standards Compliance | Meets ASTM E814, UL 1479 | Meets ASTM E814, UL 1479 |

Introduction to Fire Caulk and Fire Putty

Fire caulk and fire putty are essential materials designed to seal gaps and prevent the spread of fire, smoke, and heat in buildings. Fire caulk is a flexible, intumescent sealant that expands when exposed to high temperatures, commonly used around pipes and cables, while fire putty is a moldable compound ideal for filling irregular gaps and penetrating seal applications. Understanding the specific functions of fire caulk and fire putty helps you choose the right solution for maintaining fire-rated assemblies and enhancing building safety.

What is Fire Caulk?

Fire caulk is a specialized sealant designed to prevent the spread of fire, smoke, and toxic gases through joints and openings in walls, ceilings, and floors. Made from intumescent materials, fire caulk expands when exposed to high temperatures, creating a fire-resistant barrier that maintains the integrity of fire-rated assemblies. It is commonly used around pipes, cables, and other penetrations to enhance passive fire protection in buildings.

What is Fire Putty?

Fire putty is a heat-resistant sealing compound designed to fill gaps and seal penetrations around pipes, cables, and ducts in fire-rated walls and floors, preventing the spread of flames and smoke. It remains flexible under high temperatures, providing a reliable barrier in firestop applications where movement or vibration occurs. Fire putty is commonly applied by hand, curing quickly to form a durable, fire-resistant seal that accommodates thermal expansion and contraction.

Key Differences Between Fire Caulk and Fire Putty

Fire caulk is a flexible, intumescent sealant designed to expand and fill gaps during a fire, preventing the spread of flames and smoke through joints in walls, floors, and ceilings. Fire putty is a malleable, moldable material typically used for sealing around pipes and electrical conduits, providing a fire-resistant barrier by hardening upon exposure to heat. Your choice between the two depends on the application area and the type of firestop required, with fire caulk suited for dynamic joints and fire putty for irregular openings.

Fire Resistance Ratings and Standards

Fire caulk typically offers superior fire resistance ratings, often tested to meet ASTM E119 or UL 1479 standards for up to four hours of fire protection in joints and penetrations. Fire putty, while effective for minor sealing around electrical outlets and small gaps, generally has lower fire resistance ratings and complies with standards like UL 1479 for shorter durations, often under one hour. Understanding these distinctions ensures your firestopping materials meet the required fire resistance standards for your specific building code applications.

Application Areas: Where to Use Fire Caulk vs Fire Putty

Fire caulk is ideal for sealing gaps around electrical wires, pipes, and ducts in walls and floors to prevent the spread of fire and smoke. Fire putty is primarily used to seal penetrations in fire-resistant glass, such as glazing systems, providing flexibility and maintaining the fire rating. Both materials are essential in firestopping systems but are applied based on the specific construction element and fire resistance requirements.

Installation Process and Ease of Use

Fire caulk typically requires a precise application using a caulking gun, with careful tooling to ensure a proper seal around joints, making it ideal for narrow gaps and linear joints. Fire putty, on the other hand, is applied by hand as a malleable compound that can be pressed into irregular openings and around cables or pipes, providing versatility in complex or curved areas. The ease of use depends on the specific project: fire caulk offers cleaner lines for defined seams, while fire putty excels in filling uneven spaces without specialized tools.

Cost Comparison: Fire Caulk vs Fire Putty

Fire caulk typically costs between $8 to $15 per tube, offering an affordable solution for sealing gaps around pipes and electrical conduits with fire-resistant material. Fire putty ranges from $10 to $20 per container, generally used for penetrating firestopping in larger gaps and irregular spaces. The cost difference depends on application requirements, with fire caulk being more economical for smaller cracks and fire putty preferred for intricate or heavy-duty fire barrier needs.

Durability and Maintenance Considerations

Fire caulk offers superior durability compared to fire putty, maintaining its integrity under prolonged exposure to heat and environmental stress without frequent reapplication. Fire putty, while easier to apply for temporary seals, typically requires more regular maintenance to ensure ongoing fire resistance and proper sealing. Your choice hinges on long-term durability needs and maintenance capabilities in fire protection applications.

Choosing the Right Solution for Your Project

Fire caulk offers superior flexibility and durability for sealing large gaps around pipes and joints, making it ideal for structural firestopping in commercial and residential buildings. Fire putty, characterized by its moldable consistency, provides quick, effective sealing for smaller penetrations and can be easily applied to irregular surfaces or electrical conduit openings. Selecting between fire caulk and fire putty depends on the specific fire-resistance rating required, the size and type of the opening, and compliance with local building codes and fire safety standards.

Fire caulk vs Fire putty Infographic

libmatt.com

libmatt.com