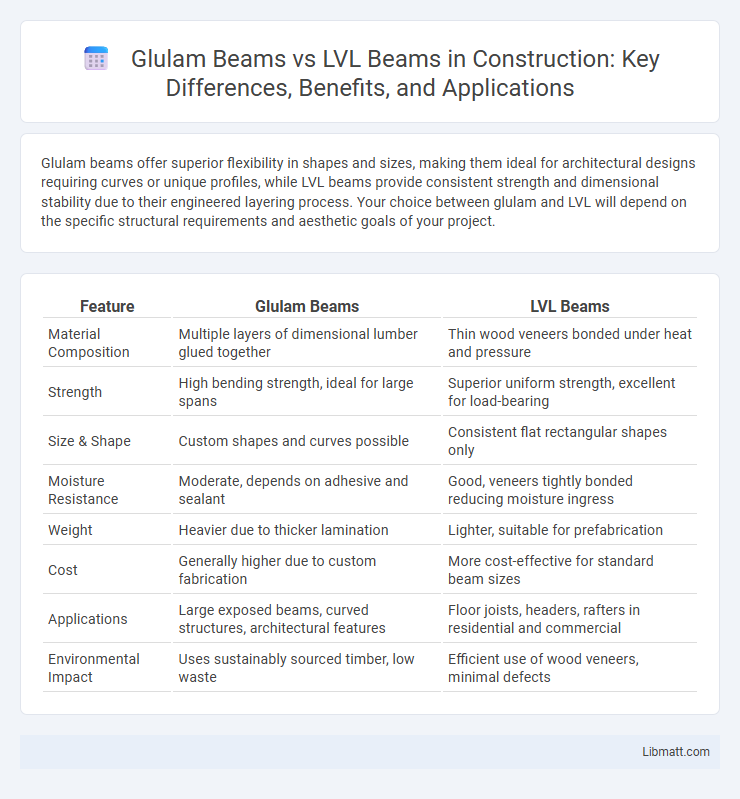

Glulam beams offer superior flexibility in shapes and sizes, making them ideal for architectural designs requiring curves or unique profiles, while LVL beams provide consistent strength and dimensional stability due to their engineered layering process. Your choice between glulam and LVL will depend on the specific structural requirements and aesthetic goals of your project.

Table of Comparison

| Feature | Glulam Beams | LVL Beams |

|---|---|---|

| Material Composition | Multiple layers of dimensional lumber glued together | Thin wood veneers bonded under heat and pressure |

| Strength | High bending strength, ideal for large spans | Superior uniform strength, excellent for load-bearing |

| Size & Shape | Custom shapes and curves possible | Consistent flat rectangular shapes only |

| Moisture Resistance | Moderate, depends on adhesive and sealant | Good, veneers tightly bonded reducing moisture ingress |

| Weight | Heavier due to thicker lamination | Lighter, suitable for prefabrication |

| Cost | Generally higher due to custom fabrication | More cost-effective for standard beam sizes |

| Applications | Large exposed beams, curved structures, architectural features | Floor joists, headers, rafters in residential and commercial |

| Environmental Impact | Uses sustainably sourced timber, low waste | Efficient use of wood veneers, minimal defects |

Introduction to Engineered Wood Beams

Engineered wood beams, such as Glulam and LVL, offer superior strength and stability compared to traditional lumber, making them ideal for modern construction. Glulam beams are composed of multiple layers of dimensioned lumber bonded with durable adhesives, providing exceptional load-bearing capabilities and aesthetic appeal. LVL beams are manufactured from thin wood veneers laminated under heat and pressure, delivering consistent performance and resistance to warping for your structural needs.

What Are Glulam Beams?

Glulam beams, or glued laminated timber beams, consist of multiple layers of dimensional lumber bonded together with strong, moisture-resistant adhesives. These beams offer exceptional strength, flexibility, and design versatility, making them ideal for long spans and architectural applications. You can rely on glulam beams for sustainable construction with enhanced load-bearing capacity and aesthetic appeal.

What Are LVL Beams?

LVL beams, or Laminated Veneer Lumber beams, are engineered wood products made by bonding thin wood veneers together under heat and pressure, producing a strong and uniform structural member. They offer high strength-to-weight ratios and dimensional stability, making them ideal for long spans and heavy loads in residential and commercial construction. You can rely on LVL beams for consistent performance and resistance to warping compared to traditional solid wood beams.

Manufacturing Processes: Glulam vs. LVL

Glulam beams are manufactured by laminating multiple layers of solid wood boards with waterproof adhesives, creating large, strong structural members that can be shaped into curves. LVL (Laminated Veneer Lumber) beams consist of thin wood veneers bonded together under heat and pressure, producing a uniform and stable product with high strength and dimensional consistency. Your choice between Glulam and LVL depends on the specific application, with Glulam offering greater design flexibility and LVL providing enhanced stability and uniformity.

Structural Strength Comparison

Glulam beams offer superior structural strength due to their layered solid wood laminations, enabling them to support heavier loads in longer spans compared to LVL beams, which are made from wood veneers bonded under heat and pressure. LVL beams provide consistent strength and dimensional stability but typically have lower load capacities and flexural strength than Glulam beams. When selecting beams for your construction project, consider Glulam for maximum load-bearing performance and LVL for projects requiring uniform strength with less weight.

Durability and Longevity

Glulam beams exhibit exceptional durability due to their layered construction, which enhances resistance to warping, splitting, and heavy loads over time. LVL beams offer superior uniformity and strength, but may require additional treatment to ensure comparable longevity in high-moisture environments. You can maximize the lifespan of either beam type by choosing appropriate finishes and installation practices tailored to your project's exposure conditions.

Aesthetic Qualities and Applications

Glulam beams offer a warm, natural wood appearance with visible grain patterns, making them ideal for exposed architectural features in residential and commercial spaces. LVL beams have a more uniform, engineered look with consistent color and texture, preferred for structural applications where appearance is secondary. You can choose Glulam for aesthetic appeal in open designs, while LVL is suited for areas requiring strength and precision.

Cost and Availability

Glulam beams generally cost more than LVL beams due to their manufacturing process involving layered timber glued with strong adhesives, but they offer superior aesthetic appeal and customization. LVL beams are widely available and often preferred for budget-sensitive projects as they provide consistent strength and durability at a lower price point. Your choice depends on balancing upfront investment against long-term performance needs in construction.

Environmental Impact and Sustainability

Glulam beams, made from layered solid wood, promote sustainability by utilizing renewable timber resources and often originate from sustainably managed forests, thus reducing carbon footprint and encouraging responsible forestry practices. LVL beams, composed of wood veneers bonded with adhesives, offer efficient use of wood by maximizing smaller or lower-quality timber, minimizing waste and contributing to environmental conservation. Choosing your construction materials with a focus on environmental impact, Glulam beams generally provide a more natural and lower-emission option compared to LVL due to their simpler manufacturing process and higher potential for recycling.

Choosing Between Glulam and LVL Beams

Glulam beams offer superior aesthetic appeal with visible wood grains and can span longer distances with greater design flexibility, making them ideal for architectural projects where visual impact matters. LVL beams provide consistent strength, uniformity, and greater resistance to warping due to their engineered layering, offering reliable structural support for demanding load conditions in your construction. When choosing between glulam and LVL beams, consider the balance between appearance, load requirements, and dimensional stability to select the best fit for your project's specific needs.

Glulam beams vs LVL beams Infographic

libmatt.com

libmatt.com