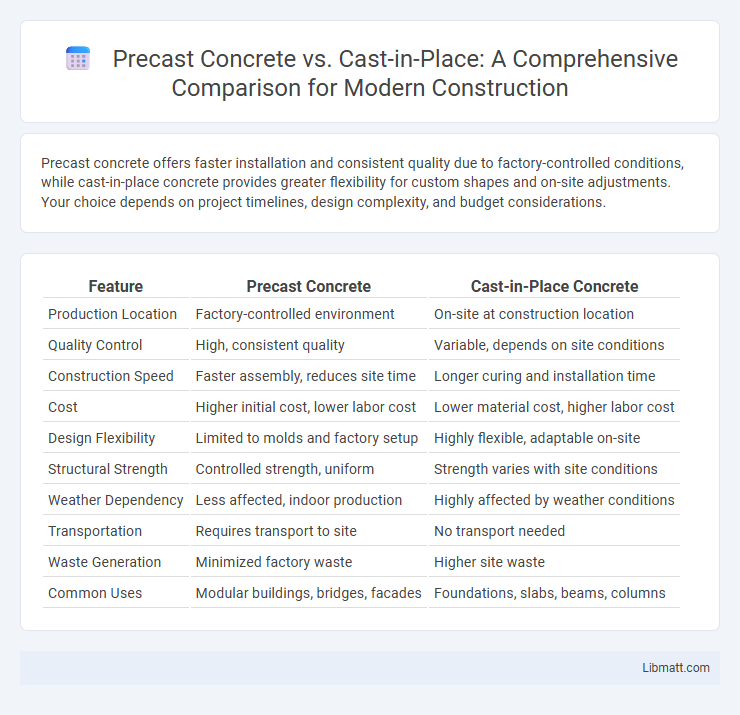

Precast concrete offers faster installation and consistent quality due to factory-controlled conditions, while cast-in-place concrete provides greater flexibility for custom shapes and on-site adjustments. Your choice depends on project timelines, design complexity, and budget considerations.

Table of Comparison

| Feature | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Production Location | Factory-controlled environment | On-site at construction location |

| Quality Control | High, consistent quality | Variable, depends on site conditions |

| Construction Speed | Faster assembly, reduces site time | Longer curing and installation time |

| Cost | Higher initial cost, lower labor cost | Lower material cost, higher labor cost |

| Design Flexibility | Limited to molds and factory setup | Highly flexible, adaptable on-site |

| Structural Strength | Controlled strength, uniform | Strength varies with site conditions |

| Weather Dependency | Less affected, indoor production | Highly affected by weather conditions |

| Transportation | Requires transport to site | No transport needed |

| Waste Generation | Minimized factory waste | Higher site waste |

| Common Uses | Modular buildings, bridges, facades | Foundations, slabs, beams, columns |

Introduction to Precast and Cast-in-Place Concrete

Precast concrete refers to concrete elements that are cast and cured in a controlled factory environment before being transported to the construction site, ensuring consistent quality and faster installation. Cast-in-place concrete is poured directly at the construction site, allowing for versatile design and seamless integration with other structural components. Choosing between precast and cast-in-place concrete depends on project requirements such as time, budget, and structural complexity, affecting your overall construction strategy.

Definition and Key Differences

Precast concrete refers to concrete elements that are cast and cured in a controlled factory environment before being transported to the construction site, while cast-in-place concrete is poured and cured directly at the construction location. Key differences include quality control, with precast offering higher consistency due to factory conditions, and flexibility, as cast-in-place allows for more complex and custom shapes on-site. Precast reduces construction time and labor costs but requires logistics for transportation, whereas cast-in-place supports monolithic structures and eliminates transportation constraints.

Manufacturing and Installation Process

Precast concrete is manufactured in controlled factory environments, ensuring uniform quality and faster curing times, which reduces on-site labor and weather-related delays. Cast-in-place concrete is mixed and poured directly on-site, allowing for greater customization and integration with existing structures but requires longer curing periods and more labor-intensive formwork. Your project timeline and site conditions largely determine whether the precision of precast or the flexibility of cast-in-place concrete is more suitable.

Speed of Construction

Precast concrete significantly accelerates construction speed by allowing components to be manufactured simultaneously off-site while site work progresses, reducing overall project timelines. Cast-in-place concrete requires sequential processes, including formwork assembly, pouring, and curing, which extend the construction period. Your project can benefit from faster assembly and earlier completion by opting for precast concrete elements.

Cost Comparison

Precast concrete typically reduces overall construction costs due to faster installation times and minimized on-site labor, leading to lower project overhead expenses. Cast-in-place concrete often incurs higher labor and formwork costs, with longer curing times impacting project schedules and increasing indirect expenses. Evaluating material, labor, and time efficiencies is crucial for determining the most cost-effective option in various construction projects.

Quality and Precision

Precast concrete offers superior quality and precision due to factory-controlled environments that minimize inconsistencies and defects, ensuring uniformity in dimensions and finishes. Cast-in-place concrete may experience variability caused by site conditions, weather, and onsite workmanship, which can affect the final strength and surface quality. Your project benefits from precast's enhanced accuracy when tight tolerances and consistent material properties are critical.

Structural Performance and Durability

Precast concrete offers superior structural performance due to factory-controlled conditions ensuring consistent quality and high compressive strength, which enhances load-bearing capacity and reduces the likelihood of defects. Cast-in-place concrete provides monolithic continuity with on-site customization, promoting effective load transfer and structural integrity, especially in complex geometries. Durability in precast elements benefits from controlled curing and reduced exposure to environmental factors during production, while cast-in-place concrete relies on proper onsite curing and quality control to resist weathering, chemical attacks, and freeze-thaw cycles.

Design Flexibility

Precast concrete offers limited design flexibility due to factory-controlled production and standardized molds, which can restrict customization of shapes and sizes. Cast-in-place concrete provides superior design versatility, allowing on-site adjustments and complex architectural forms tailored to specific project requirements. Project-specific demands influence the choice, with cast-in-place preferred for intricate designs and precast favored for repetitive, modular components.

Sustainability and Environmental Impact

Precast concrete offers significant sustainability advantages due to its controlled manufacturing environment, which minimizes waste and allows for the recycling of materials, reducing the carbon footprint compared to cast-in-place concrete. Cast-in-place concrete typically involves higher on-site energy consumption and generates greater waste, contributing to increased environmental impact. Optimizing the use of precast elements can lead to lower greenhouse gas emissions and improved resource efficiency in construction projects.

Choosing the Right Method for Your Project

Choosing between precast concrete and cast-in-place depends on project specifics such as timeline, budget, and site conditions. Precast concrete offers faster installation and consistent quality due to factory-controlled environments, ideal for repetitive or large-scale projects. Cast-in-place provides greater flexibility for complex designs and adjustments on-site, making it suitable for custom or irregular structures.

Precast concrete vs cast-in-place Infographic

libmatt.com

libmatt.com