Condensing boilers extract additional heat from exhaust gases, boosting energy efficiency and lowering fuel costs compared to non-condensing boilers that lose more heat through flue gases. Your choice impacts heating bills and environmental footprint, with condensing models offering advanced technology to maximize energy use.

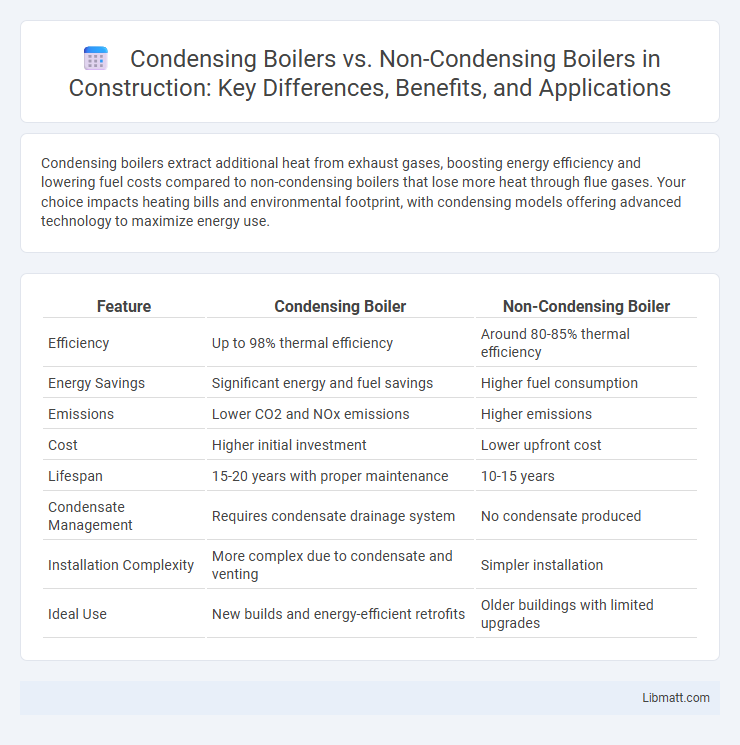

Table of Comparison

| Feature | Condensing Boiler | Non-Condensing Boiler |

|---|---|---|

| Efficiency | Up to 98% thermal efficiency | Around 80-85% thermal efficiency |

| Energy Savings | Significant energy and fuel savings | Higher fuel consumption |

| Emissions | Lower CO2 and NOx emissions | Higher emissions |

| Cost | Higher initial investment | Lower upfront cost |

| Lifespan | 15-20 years with proper maintenance | 10-15 years |

| Condensate Management | Requires condensate drainage system | No condensate produced |

| Installation Complexity | More complex due to condensate and venting | Simpler installation |

| Ideal Use | New builds and energy-efficient retrofits | Older buildings with limited upgrades |

Introduction to Condensing and Non-Condensing Boilers

Condensing boilers maximize energy efficiency by capturing and reusing heat from exhaust gases, leading to lower fuel consumption and reduced emissions compared to non-condensing models. Non-condensing boilers expel hot gases directly through the flue, resulting in higher heat loss and less efficient operation. Your choice between these systems impacts both energy bills and environmental footprint.

How Condensing Boilers Work

Condensing boilers improve efficiency by capturing and reusing heat from exhaust gases that traditional non-condensing boilers release into the atmosphere. They use a secondary heat exchanger to cool flue gases, causing water vapor to condense and release latent heat, which is then transferred back to the heating system. This process can increase fuel efficiency by up to 30%, helping You reduce energy costs and environmental impact.

How Non-Condensing Boilers Operate

Non-condensing boilers operate by heating water through combustion and expelling the hot gases directly through the flue without recovering latent heat from the steam in the exhaust. These boilers maintain higher flue gas temperatures, often above 140degC, which reduces efficiency as heat is lost with the exhaust. Typically, non-condensing boilers have lower initial costs but higher fuel consumption compared to condensing boilers that reclaim heat via condensation.

Key Efficiency Differences

Condensing boilers achieve higher efficiency by capturing and reusing heat from exhaust gases through a secondary heat exchanger, resulting in efficiency rates of up to 98%, compared to non-condensing boilers that typically operate around 70-80%. Non-condensing boilers release hot flue gases directly out of the chimney, wasting latent heat and increasing fuel consumption. The key efficiency difference lies in the ability of condensing boilers to recover latent heat, significantly reducing energy loss and lowering greenhouse gas emissions.

Environmental Impact Comparison

Condensing boilers significantly reduce carbon emissions by extracting additional heat from exhaust gases, achieving efficiency rates up to 98%, compared to non-condensing boilers that typically operate around 70-80% efficiency and release more pollutants. Your choice of a condensing boiler supports lower greenhouse gas emissions and reduced energy consumption, contributing to a greener environment. Non-condensing boilers generate higher CO2 and NOx emissions, intensifying air pollution and environmental degradation.

Installation Requirements and Considerations

Condensing boilers require a condensate drainage system and compatible flue materials to handle the acidic condensation produced during operation, which can increase installation complexity and cost. Non-condensing boilers use standard venting systems without the need for condensate drainage, making installation simpler but less energy-efficient. Your choice should consider available space, venting options, and local regulations to ensure compliance and optimal performance.

Maintenance and Longevity

Condensing boilers require regular maintenance of their heat exchanger and condensate drain to prevent corrosion and blockages, ensuring optimal efficiency and longevity. Non-condensing boilers generally have simpler maintenance needs but may experience shorter lifespan due to higher operating temperatures causing increased wear on components. You can extend the lifespan of either boiler type by scheduling annual professional inspections and prompt servicing.

Cost Analysis: Upfront and Long-Term

Condensing boilers typically have higher upfront costs due to advanced heat exchanger technology but offer significant long-term savings through improved fuel efficiency, often reaching 90-98% efficiency compared to 70-80% for non-condensing models. Your energy bills can decrease substantially with a condensing boiler, offsetting initial expenses within a few years, while non-condensing boilers may incur higher operational costs over time. Maintenance costs for condensing boilers may be slightly higher, but their enhanced performance and reduced carbon footprint make them a cost-effective choice in the long run.

Ideal Applications for Each Boiler Type

Condensing boilers are ideal for modern, energy-efficient homes with high heating demands and low return water temperatures, maximizing energy savings through heat recovery. Non-condensing boilers suit buildings with older piping systems or where lower initial costs and simpler installation are priorities, typically in well-insulated homes with moderate heating needs. Your choice between condensing and non-condensing boilers should consider the home's insulation, existing infrastructure, and long-term energy efficiency goals.

Choosing the Right Boiler for Your Needs

Selecting the right boiler involves comparing condensing and non-condensing models based on efficiency and installation costs. Condensing boilers operate at up to 98% efficiency by reclaiming heat from exhaust gases, lowering energy bills and emissions, while non-condensing boilers typically run around 70-85% efficiency with simpler, less expensive installation. Homeowners prioritizing energy savings and environmental impact benefit from condensing boilers, whereas those with budget constraints or older systems may find non-condensing options more practical.

Condensing boiler vs non-condensing Infographic

libmatt.com

libmatt.com