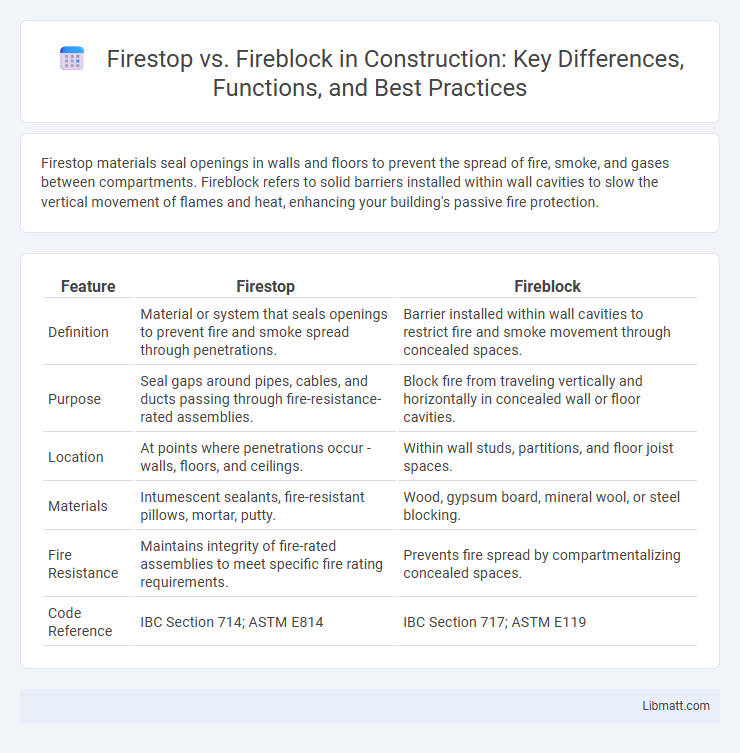

Firestop materials seal openings in walls and floors to prevent the spread of fire, smoke, and gases between compartments. Fireblock refers to solid barriers installed within wall cavities to slow the vertical movement of flames and heat, enhancing your building's passive fire protection.

Table of Comparison

| Feature | Firestop | Fireblock |

|---|---|---|

| Definition | Material or system that seals openings to prevent fire and smoke spread through penetrations. | Barrier installed within wall cavities to restrict fire and smoke movement through concealed spaces. |

| Purpose | Seal gaps around pipes, cables, and ducts passing through fire-resistance-rated assemblies. | Block fire from traveling vertically and horizontally in concealed wall or floor cavities. |

| Location | At points where penetrations occur - walls, floors, and ceilings. | Within wall studs, partitions, and floor joist spaces. |

| Materials | Intumescent sealants, fire-resistant pillows, mortar, putty. | Wood, gypsum board, mineral wool, or steel blocking. |

| Fire Resistance | Maintains integrity of fire-rated assemblies to meet specific fire rating requirements. | Prevents fire spread by compartmentalizing concealed spaces. |

| Code Reference | IBC Section 714; ASTM E814 | IBC Section 717; ASTM E119 |

Understanding Firestop vs Fireblock: Key Differences

Firestop and fireblock serve distinct roles in fire protection within buildings; firestop products seal openings and joints in fire-rated walls and floors to prevent the spread of flames, smoke, and gases, while fireblock materials impede fire movement through concealed spaces like wall cavities. Firestop systems often consist of intumescent sealants, collars, and wraps that expand under heat, ensuring compartmentalization, whereas fireblocking typically involves solid materials such as wood, drywall, or foam installed between framing members. Understanding these key differences is critical for compliance with building codes such as the International Building Code (IBC) and National Fire Protection Association (NFPA) standards.

Firestop and Fireblock: Definitions and Purposes

Firestop refers to materials and systems designed to seal openings and joints in fire-resistance-rated walls and floors, preventing the spread of fire, smoke, and heat between compartments. Fireblock involves materials installed within concealed spaces like wall cavities to restrict the spread of flames and hot gases within the structure. Understanding the distinct roles of firestop and fireblock helps you effectively enhance building fire safety by containing fire in designated areas.

Materials Used in Firestop and Fireblock Systems

Firestop systems primarily utilize materials such as intumescent sealants, fire-resistant foams, mineral wool, and fire-resistant caulks designed to expand when exposed to heat, sealing gaps around penetrations through fire-rated assemblies. Fireblock systems employ solid materials like wood, gypsum board, or metal to obstruct concealed spaces within wall cavities, preventing the spread of flames and smoke through voids. Both systems are essential in fire safety but differ in materials and application, with firestop focusing on sealing penetrations and fireblock on compartmentalizing concealed spaces.

Where Firestop Systems Are Required

Firestop systems are required in areas where fire-rated assemblies are penetrated by electrical cables, plumbing pipes, and HVAC ducts to restore the fire-resistance rating of the wall or floor. You must install firestopping in assembly joints, shaft penetrations, and through-penetrations to prevent the spread of smoke, fire, and heat. Fireblocking, in contrast, is typically used within concealed spaces like wall cavities or attic floors to slow fire movement between building components.

Common Applications for Fireblock Products

Fireblock products are primarily used in residential and commercial construction to prevent the horizontal spread of fire and smoke through concealed spaces such as wall cavities, floor joists, and attic floors. They are commonly applied in areas around plumbing pipes, electrical wiring conduits, and HVAC ducts where openings or voids exist. These fireblock materials ensure compartmentalization, improving overall fire safety by limiting fire movement within building assemblies.

Code Compliance: Firestop vs Fireblock

Firestop systems comply with strict building codes such as UL and ASTM standards, ensuring gaps around penetrations in fire-rated assemblies are sealed to prevent fire and smoke spread. Fireblocks, often required by building codes like the International Residential Code (IRC), are installed within wall cavities to restrict draft and slow fire progression by compartmentalizing concealed spaces. Both methods fulfill specific code requirements, with firestops addressing penetrations and fireblocks focusing on cavity containment for enhanced fire safety.

Installation Methods for Firestop and Fireblock

Firestop installation requires sealing penetrations in fire-rated walls and floors using specialized materials like intumescent sealants, firestop pillows, or collars to maintain fire-resistance ratings. Fireblocking is installed within wall cavities, ceilings, and floors using solid materials such as wood blocks, drywall, or mineral wool to slow the spread of fire through concealed spaces. Your choice between firestop and fireblock depends on the specific building code requirements and the areas needing protection against fire and smoke migration.

Performance Standards and Testing

Firestop systems comply with stringent performance standards such as ASTM E814 and UL 1479, which evaluate their ability to prevent fire and smoke passage through penetrations in walls and floors. Fireblocks, governed primarily by building codes like the International Residential Code (IRC), focus on compartmentalizing concealed spaces to slow fire spread but are not subject to rigorous standardized testing. Independent third-party testing laboratories certify firestops for smoke, heat, and flame resistance, ensuring reliable performance in fire scenarios.

Choosing the Right Solution: Firestop or Fireblock?

Selecting the right fire protection method depends on the application: firestop systems are designed to seal openings and joints in fire-resistance rated walls and floors to prevent fire and smoke spread, while fireblock refers to materials installed within concealed spaces, such as wall cavities, to restrict fire movement through structural voids. Firestops require certification and compliance with building codes to ensure effectiveness in maintaining fire-resistance ratings, whereas fireblocking is typically mandated for controlling fire in framing cavities according to residential and commercial codes. Understanding the specific fire risk, building design, and regulatory requirements helps determine whether a firestop system or fireblock material is the appropriate solution for fire containment.

Fire Safety Best Practices and Maintenance

Firestop and fireblock materials serve critical roles in fire safety best practices by preventing the spread of flames and smoke through penetrations and concealed spaces within buildings. Regular maintenance of firestop systems involves inspecting seals around pipes, cables, and ducts to ensure integrity, while fireblock installations require periodic verification to maintain continuous barriers within wall cavities and floor assemblies. Ensuring compliance with building codes and using UL-listed firestop products significantly enhances overall fire containment and occupant protection.

Firestop vs fireblock Infographic

libmatt.com

libmatt.com