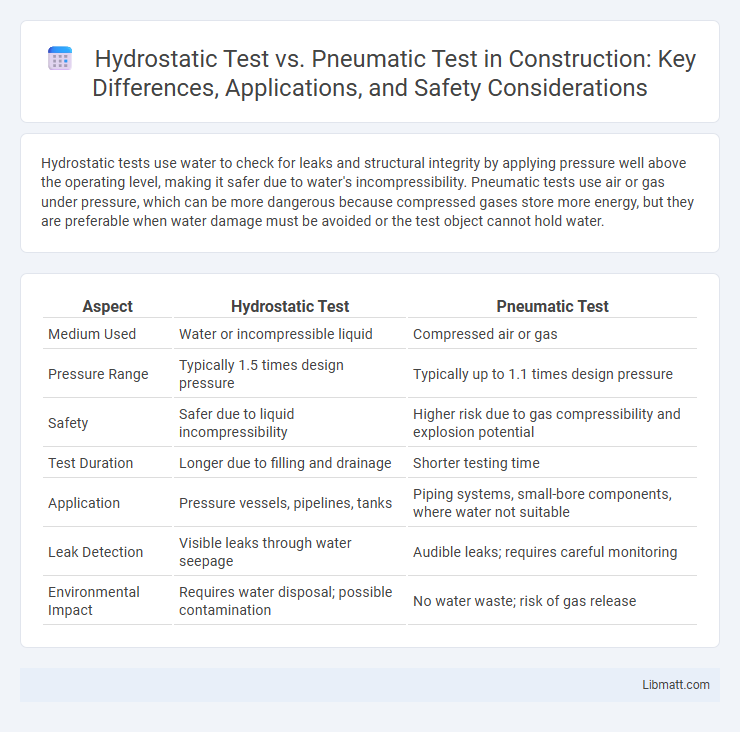

Hydrostatic tests use water to check for leaks and structural integrity by applying pressure well above the operating level, making it safer due to water's incompressibility. Pneumatic tests use air or gas under pressure, which can be more dangerous because compressed gases store more energy, but they are preferable when water damage must be avoided or the test object cannot hold water.

Table of Comparison

| Aspect | Hydrostatic Test | Pneumatic Test |

|---|---|---|

| Medium Used | Water or incompressible liquid | Compressed air or gas |

| Pressure Range | Typically 1.5 times design pressure | Typically up to 1.1 times design pressure |

| Safety | Safer due to liquid incompressibility | Higher risk due to gas compressibility and explosion potential |

| Test Duration | Longer due to filling and drainage | Shorter testing time |

| Application | Pressure vessels, pipelines, tanks | Piping systems, small-bore components, where water not suitable |

| Leak Detection | Visible leaks through water seepage | Audible leaks; requires careful monitoring |

| Environmental Impact | Requires water disposal; possible contamination | No water waste; risk of gas release |

Introduction to Pressure Testing Methods

Hydrostatic testing uses water or another incompressible fluid to assess the integrity of pipes, vessels, or systems by applying pressure beyond operating limits, ensuring safety and leak detection. Pneumatic testing employs compressed air or gas, ideal for non-water-tolerant systems, but requires stringent safety measures due to the stored energy and potential hazards. Your choice between these pressure testing methods depends on system material, application, and risk assessment needs for accurate and safe evaluation.

Overview of Hydrostatic Testing

Hydrostatic testing uses water or another incompressible liquid to check the integrity and strength of pipes, tanks, and pressure vessels by subjecting them to high pressure. It is safer than pneumatic testing because any failure typically results in a slow water leak rather than an explosive release of compressed gas. You can rely on hydrostatic testing for accurate leak detection and structural verification without the increased risk associated with pneumatic methods.

Overview of Pneumatic Testing

Pneumatic testing involves pressurizing a vessel or pipeline with air or an inert gas, often nitrogen, to detect leaks or structural weaknesses. This method is favored for equipment that cannot tolerate water or contamination and typically uses pressures up to 1.5 times the design pressure. Pneumatic testing requires stringent safety protocols due to the potential energy stored in compressed gases, making it critical for ensuring integrity without liquid-based testing.

Key Applications of Hydrostatic and Pneumatic Tests

Hydrostatic tests are primarily used in industries such as oil and gas, chemical processing, and water treatment to verify the integrity of pipelines, pressure vessels, and boilers by filling them with water and applying pressure beyond operational limits. Pneumatic tests find key applications in systems where water presence poses risks, including air and gas pipelines, HVAC systems, and compressed air tanks, using compressed air or inert gases for pressure testing. Your choice between these tests depends on material compatibility, safety considerations, and the specific regulatory requirements of the application environment.

Comparison of Testing Procedures

Hydrostatic testing involves filling the test object with water or another incompressible liquid and pressurizing it to a specified level to check for leaks and structural integrity, making it safer due to the incompressibility of the fluid. Pneumatic testing uses compressed air or gas to pressurize the object, allowing for quicker testing but increasing risks due to the compressibility and potential energy stored in the gas. The choice between hydrostatic and pneumatic testing depends on factors such as safety requirements, test pressure levels, and the nature of the equipment being tested.

Safety Considerations: Hydrostatic vs Pneumatic

Hydrostatic tests use water to pressurize systems, reducing risk due to water's incompressibility, making them safer in case of failure compared to pneumatic tests which use compressed air. Pneumatic tests carry higher explosion hazards because air is highly compressible, increasing the energy released upon failure and posing greater risk to personnel and equipment. Your safety protocols should prioritize hydrostatic testing when possible, especially in confined spaces or pressurized vessel inspections.

Advantages of Hydrostatic Testing

Hydrostatic testing offers superior safety by using water, an incompressible fluid, which reduces the risk of explosive accidents compared to pneumatic tests that use compressed air. It provides accurate detection of leaks and structural weaknesses under pressure conditions that closely simulate actual operating environments. Your inspection process benefits from the cost-effectiveness and environmental safety of hydrostatic tests, making it a preferred choice for pipeline and pressure vessel integrity assessments.

Advantages of Pneumatic Testing

Pneumatic testing offers significant advantages such as faster test cycles and the ability to detect very small leaks due to the compressibility of air or gas, making it suitable for systems where water contamination must be avoided. It is especially beneficial for testing pipes and vessels that cannot withstand the additional weight and corrosion risks associated with hydrostatic testing. The method reduces downtime and material expenses, optimizing efficiency in industrial pressure system assessments.

Limitations and Risks of Each Method

Hydrostatic tests present limitations such as the need for large volumes of water, potential environmental hazards from leaks, and the risk of water freezing in cold conditions, while pneumatic tests carry higher risks due to the compressibility of air or gas, which can lead to explosive failures if a leak or rupture occurs. Hydrostatic testing is generally safer since water is incompressible, but it may not detect certain types of leaks as effectively as pneumatic tests, which are more sensitive but require stringent safety precautions. You should carefully evaluate the specific equipment and operating conditions to select the appropriate test method minimizing risks and ensuring accurate pressure integrity assessment.

Choosing the Right Pressure Test for Your Project

Selecting the appropriate pressure test for your project depends on factors such as safety, test medium, and equipment sensitivity. Hydrostatic tests use water to detect leaks and structural integrity, ideal for high-pressure systems and pipelines due to water's incompressibility and minimal risk of explosion. Pneumatic tests employ compressed air or gas, offering faster testing but higher risk, making them suitable for applications where water damage must be avoided or when testing non-watertight components.

Hydrostatic test vs Pneumatic test Infographic

libmatt.com

libmatt.com