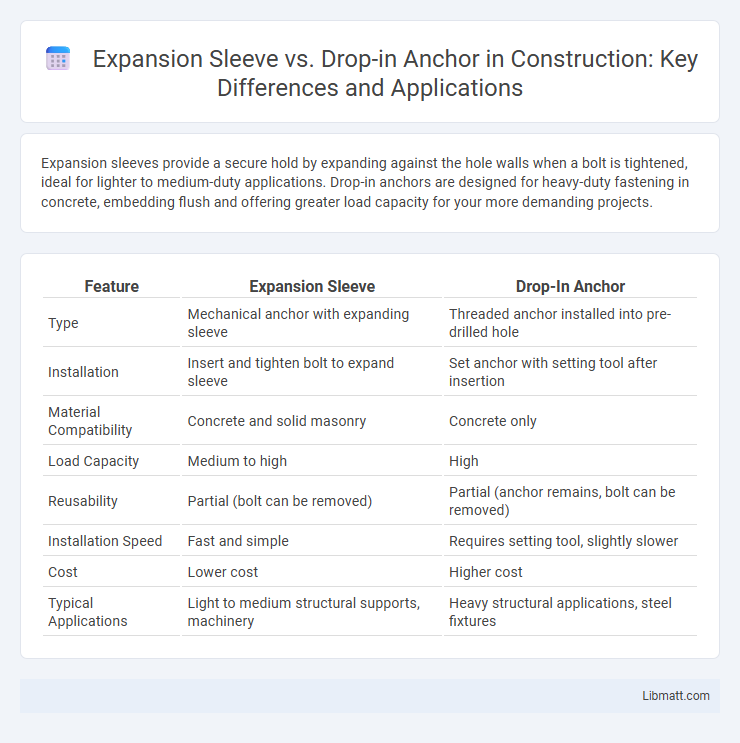

Expansion sleeves provide a secure hold by expanding against the hole walls when a bolt is tightened, ideal for lighter to medium-duty applications. Drop-in anchors are designed for heavy-duty fastening in concrete, embedding flush and offering greater load capacity for your more demanding projects.

Table of Comparison

| Feature | Expansion Sleeve | Drop-In Anchor |

|---|---|---|

| Type | Mechanical anchor with expanding sleeve | Threaded anchor installed into pre-drilled hole |

| Installation | Insert and tighten bolt to expand sleeve | Set anchor with setting tool after insertion |

| Material Compatibility | Concrete and solid masonry | Concrete only |

| Load Capacity | Medium to high | High |

| Reusability | Partial (bolt can be removed) | Partial (anchor remains, bolt can be removed) |

| Installation Speed | Fast and simple | Requires setting tool, slightly slower |

| Cost | Lower cost | Higher cost |

| Typical Applications | Light to medium structural supports, machinery | Heavy structural applications, steel fixtures |

Understanding Expansion Sleeves

Expansion sleeves provide a reliable mechanical fastening solution by gripping the interior of a drilled hole through radial expansion. They are ideal for medium to heavy-duty anchoring in concrete, masonry, and stone, offering excellent load distribution and vibration resistance. Designed for applications requiring secure, removable, or adjustable fixtures, expansion sleeves ensure stable anchorage without damaging the base material.

Overview of Drop-In Anchors

Drop-in anchors are a type of expansion anchor designed for use in solid concrete, providing reliable and strong holding power by expanding inside a drilled hole when the anchor is set. They are ideal for medium to heavy-duty fastening applications, such as securing machinery, shelving, or structural supports. Your choice of drop-in anchors offers flush installation without protruding parts, making them a versatile solution for clean and secure anchor points.

Key Differences Between Expansion Sleeves and Drop-In Anchors

Expansion sleeves provide a mechanical grip by expanding against the hole wall when a bolt is tightened, making them ideal for lighter loads and medium-duty applications. Drop-in anchors require setting with a setting tool that expands the anchor internally, offering higher load capacity and greater stability in heavy-duty concrete fixing scenarios. The choice between expansion sleeves and drop-in anchors depends on load requirements, installation method, and type of base material used.

Material Compatibility and Applications

Expansion sleeves, typically made from carbon steel or stainless steel, offer strong compatibility with concrete and masonry materials, making them ideal for heavy-duty applications like structural supports and machinery installations. Drop-in anchors, crafted from stainless steel or zinc-plated steel, provide reliable performance in solid concrete, especially in overhead or flush-mount situations such as HVAC systems and electrical fixtures. Your choice between these anchors depends on material compatibility and specific application requirements, with expansion sleeves excelling in high-load scenarios and drop-in anchors favored for versatility and ease of installation in concrete substrates.

Installation Process Comparison

Expansion sleeves require drilling a precise hole diameter matching the sleeve size, followed by inserting the sleeve and tightening the bolt to expand the metal sleeve against the hole walls, creating a secure hold. Drop-in anchors involve drilling a hole to the anchor's length, inserting the anchor flush with the surface, and setting it with a setting tool or hammer to expand the internal plug for firm anchoring. Installation of drop-in anchors is often considered quicker and cleaner in overhead or confined spaces compared to expansion sleeves, which demand more torque for full expansion.

Load Capacity and Performance

Expansion sleeves generally provide high load capacity in tension applications by gripping tightly against the hole wall, making them suitable for heavy-duty fastening in solid concrete. Drop-in anchors excel in providing reliable load performance under shear and vibration due to their internal expansion mechanism, which offers consistent holding power in hollow or cracked concrete. Choosing the right anchor depends on your project's specific load demands and the structural conditions where maximum performance is critical.

Advantages of Expansion Sleeves

Expansion sleeves offer superior load-bearing capacity and are ideal for securing heavy fixtures in solid concrete due to their reliable mechanical interlock. They provide excellent resistance to vibration and dynamic loads, making them suitable for structural applications in construction and industrial settings. Installation of expansion sleeves is straightforward with no need for adhesives, resulting in faster and cleaner anchoring compared to drop-in anchors.

Benefits of Drop-In Anchors

Drop-in anchors provide superior holding strength in solid concrete, making them ideal for heavy-duty applications like structural supports and machinery installation. Their internally threaded design allows for easy attachment and removal of bolts, enhancing versatility and reusability in construction projects. Unlike expansion sleeves, drop-in anchors minimize surface damage and ensure a flush finish, improving both safety and aesthetics on the job site.

Common Mistakes to Avoid

Common mistakes to avoid when using expansion sleeves include overtightening, which can crack the base material, and selecting the wrong sleeve size for the hole diameter, leading to inadequate holding power. For drop-in anchors, failing to properly clean the drilled hole or not using the correct setting tool results in poor anchor expansion and reduced load capacity. Ensuring precise hole depth and proper installation technique is crucial for both anchors to maintain structural integrity and safety.

Choosing the Right Anchor for Your Project

Choosing the right anchor for your project hinges on the substrate and load requirements: expansion sleeves provide strong mechanical grip ideal for solid concrete and heavy loads, while drop-in anchors excel in overhead applications and offer flush mounting in solid substrates. Expansion sleeves expand outward to create a tight grip within pre-drilled holes, ensuring high resistance to pullout forces, making them suitable for structural supports and heavy-duty fixtures. Drop-in anchors, installed flush with the surface, are preferred for anchoring into solid concrete when a clean finish and vibration resistance are critical, especially in fastening machinery and handrails.

Expansion sleeve vs Drop-in anchor Infographic

libmatt.com

libmatt.com