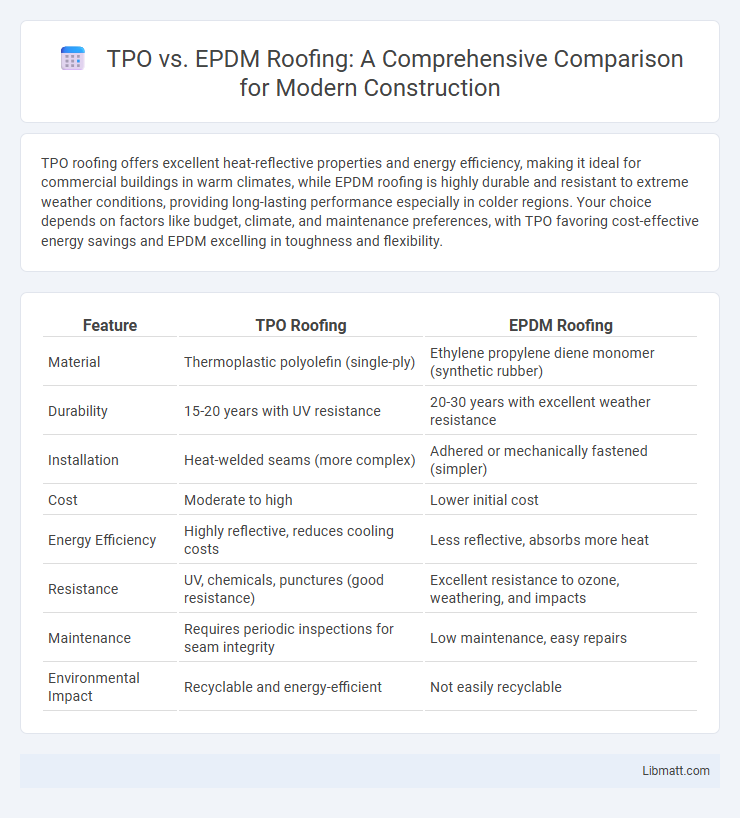

TPO roofing offers excellent heat-reflective properties and energy efficiency, making it ideal for commercial buildings in warm climates, while EPDM roofing is highly durable and resistant to extreme weather conditions, providing long-lasting performance especially in colder regions. Your choice depends on factors like budget, climate, and maintenance preferences, with TPO favoring cost-effective energy savings and EPDM excelling in toughness and flexibility.

Table of Comparison

| Feature | TPO Roofing | EPDM Roofing |

|---|---|---|

| Material | Thermoplastic polyolefin (single-ply) | Ethylene propylene diene monomer (synthetic rubber) |

| Durability | 15-20 years with UV resistance | 20-30 years with excellent weather resistance |

| Installation | Heat-welded seams (more complex) | Adhered or mechanically fastened (simpler) |

| Cost | Moderate to high | Lower initial cost |

| Energy Efficiency | Highly reflective, reduces cooling costs | Less reflective, absorbs more heat |

| Resistance | UV, chemicals, punctures (good resistance) | Excellent resistance to ozone, weathering, and impacts |

| Maintenance | Requires periodic inspections for seam integrity | Low maintenance, easy repairs |

| Environmental Impact | Recyclable and energy-efficient | Not easily recyclable |

Introduction to TPO and EPDM Roofing

TPO (Thermoplastic Olefin) roofing is a single-ply membrane known for its heat-reflective properties and energy efficiency, typically composed of a blend of polypropylene and ethylene-propylene rubber. EPDM (Ethylene Propylene Diene Monomer) roofing is a durable synthetic rubber membrane, renowned for its excellent resistance to UV rays, ozone, and weathering over long periods. Both roofing systems offer versatile solutions for commercial and industrial buildings, with TPO favored for its heat-welded seams and EPDM prized for its seamless application and elasticity.

What is TPO Roofing?

TPO roofing, or Thermoplastic Olefin roofing, is a single-ply membrane made of a blend of polypropylene and ethylene-propylene rubber, known for its durability and energy efficiency. It provides excellent resistance to ultraviolet radiation, chemical exposure, and punctures, making it a popular choice for commercial flat roofs. TPO membranes are heat-welded at the seams, creating a strong, watertight bond that enhances the roof's longevity and performance.

What is EPDM Roofing?

EPDM roofing is a durable, synthetic rubber membrane widely used in commercial and residential flat roofing systems due to its excellent weather resistance and flexibility. Composed mainly of ethylene propylene diene monomer, EPDM offers superior protection against UV rays, ozone, and extreme temperatures. Its single-ply installation method provides long-lasting waterproofing with minimal maintenance compared to other roofing materials like TPO.

TPO vs EPDM: Material Composition

TPO roofing is made from a blend of polypropylene and ethylene-propylene rubber, offering heat-reflective properties and UV resistance, while EPDM roofing consists of a synthetic rubber elastomer, known for its flexibility and durability in various weather conditions. Both materials provide excellent waterproofing, but TPO tends to be more energy-efficient due to its reflective surface, whereas EPDM is favored for its proven longevity and resistance to ozone and oxidation. Understanding the material composition helps you choose the best roofing solution based on performance requirements and environmental factors.

Durability Comparison: TPO and EPDM

TPO roofing offers excellent resistance to UV rays, ozone, and chemical exposure, typically lasting 15-20 years, while EPDM roofs demonstrate superior flexibility and weather resistance, often exceeding 20-30 years in durability. EPDM's synthetic rubber composition provides exceptional resistance to extreme temperatures and physical damage, making it highly durable in varied climates. TPO membranes, though durable, are more prone to shrinkage and seam failure compared to EPDM's robust, heat-welded seams that enhance longevity.

Energy Efficiency: TPO vs EPDM

TPO roofing offers superior energy efficiency due to its reflective white surface, which significantly reduces heat absorption and lowers cooling costs. EPDM, typically black, absorbs more heat, leading to higher energy consumption in warmer climates. Choosing TPO can enhance building sustainability by improving thermal performance and reducing overall energy expenses.

Installation Process Differences

TPO roofing installation involves heat-welding seams using specialized hot-air tools, creating a strong, watertight bond, whereas EPDM roofing primarily uses adhesive or mechanical fasteners to secure seams and edges. TPO systems often require trained professionals due to the precision needed in welding, while EPDM offers more flexibility for DIY or straightforward installation methods. The differing installation techniques impact labor time and costs, with TPO typically requiring more specialized equipment and expertise compared to the simpler, adhesive-based application of EPDM.

Maintenance and Repair Considerations

TPO roofing requires regular inspections to identify seam issues and potential punctures, making maintenance manageable with prompt patching and seam repairs, which helps extend its lifespan. EPDM roofing is highly resistant to weathering and UV radiation, resulting in fewer repairs, but any rips or tears should be addressed quickly using adhesive patches to prevent water damage. Understanding these maintenance and repair considerations will help you maintain roofing performance and reduce long-term costs.

Cost Analysis: TPO vs EPDM

TPO roofing typically offers a lower initial installation cost compared to EPDM, making it a budget-friendly option for many commercial projects. While EPDM has a higher upfront cost, its proven durability and longer lifespan can result in lower maintenance and replacement expenses over time. Evaluating Your roofing needs against these cost factors can help determine the better long-term investment.

Choosing Between TPO and EPDM for Your Roof

TPO roofing offers excellent heat reflectivity and energy efficiency, making it ideal for commercial buildings in warmer climates, while EPDM roofing provides superior durability and flexibility, especially suited for regions with extreme weather fluctuations. TPO membranes typically feature heat-welded seams that enhance water resistance, compared to EPDM's taped or glued seams, which may require more maintenance over time. Consider factors such as climate, budget, installation method, and long-term performance when choosing between TPO and EPDM for your roofing needs.

TPO vs EPDM roofing Infographic

libmatt.com

libmatt.com