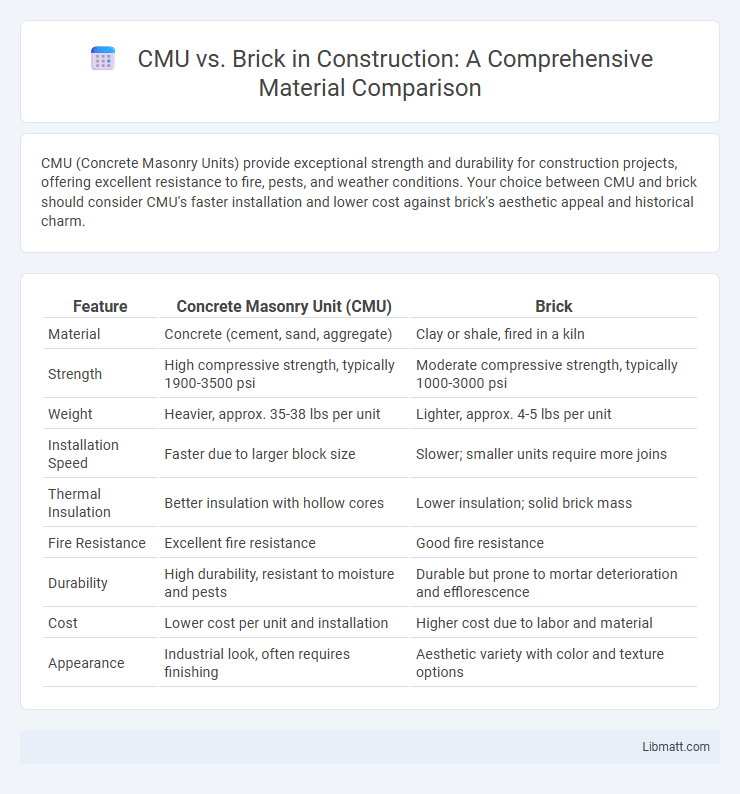

CMU (Concrete Masonry Units) provide exceptional strength and durability for construction projects, offering excellent resistance to fire, pests, and weather conditions. Your choice between CMU and brick should consider CMU's faster installation and lower cost against brick's aesthetic appeal and historical charm.

Table of Comparison

| Feature | Concrete Masonry Unit (CMU) | Brick |

|---|---|---|

| Material | Concrete (cement, sand, aggregate) | Clay or shale, fired in a kiln |

| Strength | High compressive strength, typically 1900-3500 psi | Moderate compressive strength, typically 1000-3000 psi |

| Weight | Heavier, approx. 35-38 lbs per unit | Lighter, approx. 4-5 lbs per unit |

| Installation Speed | Faster due to larger block size | Slower; smaller units require more joins |

| Thermal Insulation | Better insulation with hollow cores | Lower insulation; solid brick mass |

| Fire Resistance | Excellent fire resistance | Good fire resistance |

| Durability | High durability, resistant to moisture and pests | Durable but prone to mortar deterioration and efflorescence |

| Cost | Lower cost per unit and installation | Higher cost due to labor and material |

| Appearance | Industrial look, often requires finishing | Aesthetic variety with color and texture options |

Introduction to CMU and Brick

Concrete Masonry Units (CMU) are standardized, high-strength building blocks made primarily from cement, aggregates, and water, widely used for structural walls and foundations due to their durability and fire resistance. Bricks, traditionally made from clay and fired in kilns, offer excellent thermal insulation and aesthetic versatility but generally possess lower compressive strength compared to CMUs. Both materials serve crucial roles in construction, with CMUs preferred for load-bearing applications and bricks favored for decorative facades and partition walls.

Composition and Material Properties

CMU (Concrete Masonry Unit) consists primarily of Portland cement, aggregates, and water, creating a dense, durable material with excellent compressive strength and fire resistance. Brick is typically made from clay or shale that is molded and kiln-fired, resulting in a material with high thermal mass, weather resistance, and moderate tensile strength. Your choice between CMU and brick should consider these material properties to match structural requirements and environmental conditions effectively.

Structural Strength and Durability

CMU (Concrete Masonry Units) offer superior structural strength compared to traditional brick due to their larger size and reinforced core, making them ideal for load-bearing walls in commercial and industrial construction. CMUs exhibit enhanced durability against weathering, fire, and pests, maintaining integrity in harsh environmental conditions better than standard clay bricks. Resistance to cracking and moisture infiltration in CMUs contributes to long-term stability and reduced maintenance requirements relative to brick masonry.

Thermal Insulation and Energy Efficiency

CMU (Concrete Masonry Units) provide moderate thermal insulation with an R-value typically around 1.1 per inch, while brick offers slightly better thermal mass that helps regulate indoor temperatures but has a lower R-value of about 0.2 per inch. For enhanced energy efficiency, combining brick with insulation materials significantly improves performance, whereas CMU walls often incorporate insulation cores or external foam panels to achieve higher thermal resistance. Your choice should consider climate and desired energy savings, as CMU with added insulation generally outperforms solid brick in reducing heating and cooling costs.

Cost Comparison and Affordability

CMU (Concrete Masonry Units) generally offer a more affordable option compared to brick, with average costs ranging from $4 to $7 per square foot, whereas brick can cost between $6 to $12 per square foot due to higher material and labor expenses. The lower cost of CMU makes it suitable for large-scale projects or budget-conscious construction without significantly compromising durability or fire resistance. If your priority is managing construction expenses, CMU may provide better value without sacrificing essential structural benefits.

Construction Speed and Ease of Installation

CMU (Concrete Masonry Units) offers moderate construction speed due to its uniform size and stackable design, which simplifies installation but requires skilled labor for mortar application and alignment. Brick installation is generally slower because each unit is smaller and laid individually, necessitating careful mortar work and alignment, though experienced masons can achieve high precision and aesthetic quality. Both materials demand different skill sets, with CMUs providing faster structural assembly while bricks excel in detailed finishes, impacting overall project timelines based on labor expertise.

Aesthetic Versatility and Design Options

CMU (Concrete Masonry Units) offer a wide range of textures, colors, and finishes, allowing architects to create both modern and traditional aesthetics with high customization potential. Brick provides timeless beauty with its natural variation in hue and pattern, enhancing architectural detail while ensuring durability and classic appeal. Both materials deliver excellent design flexibility, but CMU allows more variation in shapes and sizes, expanding creative possibilities for unique and complex structures.

Maintenance Requirements and Lifespan

CMU (Concrete Masonry Units) require minimal maintenance due to their resistance to pests, fire, and moisture, extending their lifespan beyond 50 years with occasional tuckpointing and sealing. Brick offers excellent durability and low maintenance, with natural resistance to weathering and can last over 100 years when properly maintained. Your choice between CMU and brick should consider the trade-off between CMU's cost-effective maintenance and brick's superior longevity.

Environmental Impact and Sustainability

CMU (Concrete Masonry Units) offer substantial environmental advantages through high thermal mass, reducing energy consumption in buildings by stabilizing indoor temperatures. Brick production, while traditionally energy-intensive due to kiln firing, has seen improvements with modern technologies decreasing carbon emissions and incorporating recycled materials. Sustainable construction increasingly favors CMU for their potential to utilize industrial by-products like fly ash, lowering the carbon footprint compared to conventional brick masonry.

Best Applications: When to Use CMU vs Brick

CMU (Concrete Masonry Unit) is ideal for structural applications requiring high load-bearing capacity, such as retaining walls, foundations, and commercial buildings. Brick excels in aesthetic-driven projects, including residential facades, fireplaces, and decorative walls, offering superior visual appeal and weather resistance. You should choose CMU for durability and strength in construction, while brick is preferable for design-focused elements enhancing architectural beauty.

CMU vs Brick Infographic

libmatt.com

libmatt.com