Float glass offers a smooth, flat surface ideal for windows and mirrors, while tempered glass undergoes heat treatment to enhance strength and safety by shattering into small, less harmful pieces upon impact. Your choice depends on whether you prioritize cost-efficiency and clarity or increased durability and safety for applications like vehicle windows or shower doors.

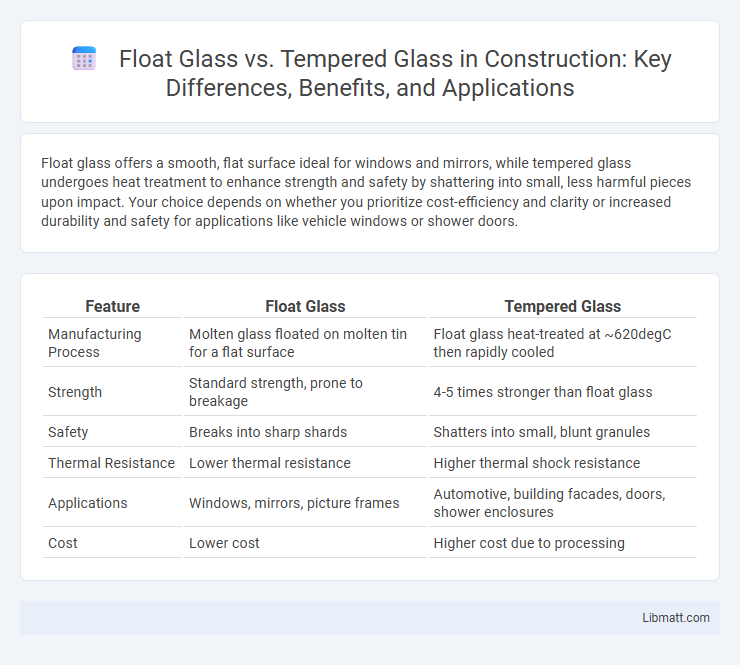

Table of Comparison

| Feature | Float Glass | Tempered Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin for a flat surface | Float glass heat-treated at ~620degC then rapidly cooled |

| Strength | Standard strength, prone to breakage | 4-5 times stronger than float glass |

| Safety | Breaks into sharp shards | Shatters into small, blunt granules |

| Thermal Resistance | Lower thermal resistance | Higher thermal shock resistance |

| Applications | Windows, mirrors, picture frames | Automotive, building facades, doors, shower enclosures |

| Cost | Lower cost | Higher cost due to processing |

Introduction to Float Glass and Tempered Glass

Float glass is a basic architectural glass made by floating molten glass on a bed of molten metal, resulting in a smooth, uniform thickness and surface, ideal for windows and mirrors. Tempered glass is produced by rapidly cooling heated float glass, significantly increasing its strength and making it shatter into small, blunt pieces for safety. Understanding these differences helps you choose the right glass type for your building or design project based on durability and safety requirements.

Manufacturing Processes Compared

Float glass is produced by floating molten glass on a bed of molten tin, resulting in a smooth and uniform surface with consistent thickness, primarily used for windows and picture frames. Tempered glass undergoes an additional process of rapid heating and cooling after float glass production, enhancing its strength and safety by inducing compressive stresses on the surface. The difference in manufacturing processes directly influences the mechanical properties, with tempered glass offering higher impact resistance and thermal durability compared to standard float glass.

Physical and Optical Properties

Float glass, characterized by its flat, smooth surface and uniform thickness, offers high optical clarity with minimal distortion, making it ideal for windows and display panels. Tempered glass, derived from heat-treated float glass, possesses significantly enhanced strength and resistance to impact and thermal stress, while maintaining comparable optical properties due to its controlled cooling process. Your choice between these two glass types should consider the need for safety and durability versus cost and optical precision.

Strength and Durability Differences

Tempered glass offers significantly higher strength and durability compared to float glass due to its heat treatment process, which increases its resistance to impact and thermal stress. Float glass is more prone to breakage since it is annealed and lacks the reinforcement that tempered glass provides. When safety and durability are priorities, your best choice is tempered glass, especially in applications requiring enhanced strength and shatter resistance.

Safety and Breakage Patterns

Float glass shatters into large, sharp shards that pose significant safety hazards upon breakage, increasing the risk of injury. Tempered glass is engineered to break into small, blunt granules that minimize harm, making it a safer choice for applications where human impact is likely. The controlled breakage pattern of tempered glass enhances safety in automotive, architectural, and consumer product uses.

Applications in Architecture and Design

Float glass is widely used for windows, facades, and interior partitions due to its clarity, smooth surface, and ease of fabrication, making it ideal for architectural designs requiring large, flat panes. Tempered glass, known for its enhanced strength and safety properties, is preferred in applications such as structural glazing, glass doors, balustrades, and skylights where impact resistance and thermal durability are critical. Both types contribute uniquely to modern architecture, with float glass providing aesthetic flexibility and tempered glass ensuring safety compliance and structural integrity.

Cost and Availability Factors

Float glass generally costs less due to its simpler manufacturing process and widespread availability in standard sizes, making it a cost-effective option for large projects. Tempered glass, which undergoes additional heat treatment to enhance strength and safety, commands a higher price and may have longer lead times due to specialized production requirements. Availability of tempered glass can be limited in certain regions, affecting delivery speed and inventory levels compared to the readily accessible float glass.

Energy Efficiency and Insulation

Tempered glass offers better energy efficiency and insulation compared to float glass due to its enhanced strength and durability, which minimizes air leakage and improves thermal performance. Float glass, while more affordable, lacks the structural integrity to provide significant insulation benefits, making it less effective in reducing energy consumption. Choosing tempered glass for your windows can lead to lower heating and cooling costs by maintaining a more consistent indoor temperature.

Maintenance and Longevity

Float glass requires regular cleaning and careful handling to prevent scratches and chips, while tempered glass offers enhanced durability and resistance to impact, reducing maintenance needs. The thermal strength of tempered glass also minimizes the risk of breakage due to temperature changes, extending your glass installations' longevity. Choosing tempered glass can significantly reduce replacement frequency and associated costs over time.

Choosing the Right Glass for Your Project

Float glass offers a smooth and uniform surface ideal for decorative purposes and interior applications but lacks impact resistance, making it less suitable for safety-critical projects. Tempered glass undergoes heat treatment to enhance strength and shatter into small, blunt pieces, making it essential for applications requiring safety, such as windows, doors, and automotive glass. Selecting the right glass depends on balancing factors like safety requirements, durability, cost, and aesthetic preferences to ensure optimal performance in your specific project.

Float glass vs tempered glass Infographic

libmatt.com

libmatt.com