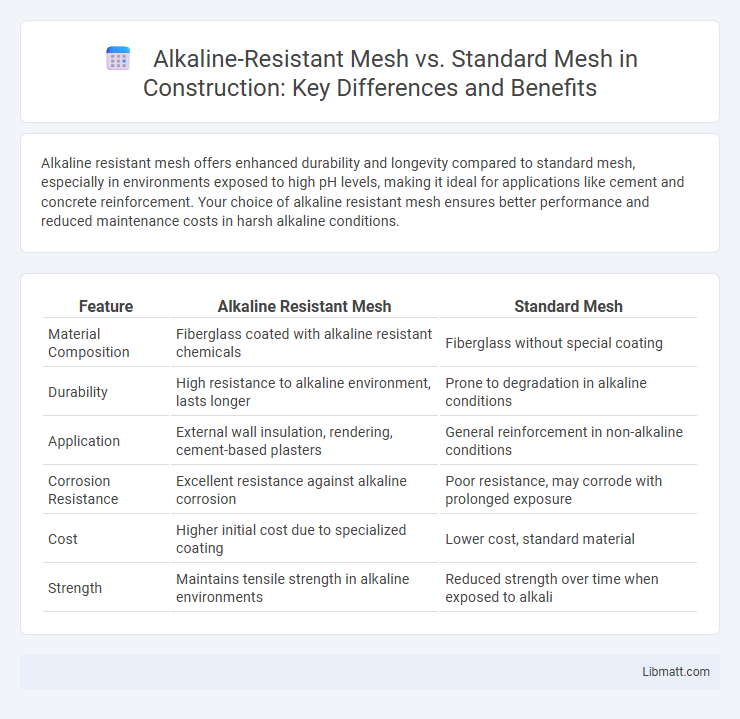

Alkaline resistant mesh offers enhanced durability and longevity compared to standard mesh, especially in environments exposed to high pH levels, making it ideal for applications like cement and concrete reinforcement. Your choice of alkaline resistant mesh ensures better performance and reduced maintenance costs in harsh alkaline conditions.

Table of Comparison

| Feature | Alkaline Resistant Mesh | Standard Mesh |

|---|---|---|

| Material Composition | Fiberglass coated with alkaline resistant chemicals | Fiberglass without special coating |

| Durability | High resistance to alkaline environment, lasts longer | Prone to degradation in alkaline conditions |

| Application | External wall insulation, rendering, cement-based plasters | General reinforcement in non-alkaline conditions |

| Corrosion Resistance | Excellent resistance against alkaline corrosion | Poor resistance, may corrode with prolonged exposure |

| Cost | Higher initial cost due to specialized coating | Lower cost, standard material |

| Strength | Maintains tensile strength in alkaline environments | Reduced strength over time when exposed to alkali |

Understanding Alkaline Resistant Mesh and Standard Mesh

Alkaline resistant mesh is specifically designed to withstand high pH environments commonly found in cement and concrete, ensuring durability and preventing corrosion over time. Standard mesh lacks this resistance, making it prone to degradation and reduced structural integrity when exposed to alkaline materials. Choosing alkaline resistant mesh for your construction projects enhances longevity and performance compared to standard mesh options.

Key Material Differences Between Alkaline Resistant and Standard Mesh

Alkaline resistant mesh is primarily made with fiberglass coated in a specialized epoxy resin, which provides enhanced durability and resistance to the high pH levels commonly found in concrete environments. Standard mesh typically consists of uncoated or vinyl-coated fiberglass, which is prone to degradation when exposed to alkaline substances. The epoxy resin coating on alkaline resistant mesh significantly extends the lifespan and structural integrity of reinforced concrete by preventing corrosion and weakening of the mesh fibers.

Chemical Resistance: Why Alkaline Matters in Mesh Selection

Alkaline resistant mesh offers superior chemical resistance compared to standard mesh, making it essential for environments with high alkaline exposure such as concrete or cement applications. Standard mesh materials can deteriorate quickly when subjected to alkaline substances, leading to reduced durability and potential structural issues. Choosing alkaline resistant mesh ensures your project maintains integrity and longevity by effectively resisting chemical degradation.

Performance in Concrete Applications

Alkaline resistant mesh outperforms standard mesh in concrete applications by resisting degradation caused by the high pH levels in cement mixtures, ensuring long-term durability and structural integrity. This enhanced resistance minimizes corrosion and extends the lifespan of reinforced concrete structures. Using alkaline resistant mesh in Your projects guarantees improved performance and reduced maintenance costs over time.

Durability and Longevity: Alkaline Resistant vs Standard Mesh

Alkaline resistant mesh is engineered to withstand the corrosive effects of alkaline environments commonly found in concrete, providing superior durability compared to standard mesh, which often degrades and weakens over time. This enhanced resistance ensures a longer lifespan for reinforcement applications, reducing the need for frequent repairs and maintenance. Your construction projects benefit from improved structural integrity and cost efficiency by choosing alkaline resistant mesh over standard options.

Cost Comparison of Alkaline Resistant Mesh and Standard Alternatives

Alkaline resistant (AR) mesh typically costs 20-30% more than standard fiberglass mesh due to its enhanced durability against high pH environments, extending the lifespan of construction materials it reinforces. While the upfront investment is higher, AR mesh reduces long-term maintenance and replacement expenses, offering better value for projects involving cementitious applications like external plastering and tile installation. Standard mesh, although cheaper initially, may degrade faster in alkaline conditions, leading to frequent repairs and increased overall costs.

Installation Process: Ease of Use for Both Mesh Types

Alkaline resistant mesh offers a smoother installation process due to its enhanced durability and flexibility compared to standard mesh, reducing handling difficulties and installation time. Standard mesh may require extra care to prevent damage from alkaline substances in materials like concrete, making it less user-friendly during setup. You will find alkaline resistant mesh more reliable and easier to work with, especially in environments exposed to high alkalinity.

Common Industry Uses for Each Mesh Type

Alkaline resistant mesh is primarily used in construction applications involving cement and concrete, such as EIFS (External Insulation and Finish Systems), stucco reinforcement, and tile backing, where durability against alkali degradation is critical. Standard mesh finds common use in general indoor applications like window screens, insect screens, and light filtration, where exposure to harsh environments is minimal. The choice between alkaline resistant and standard mesh depends on the specific environmental conditions and longevity requirements of the project.

Environmental and Safety Considerations

Alkaline resistant mesh offers superior durability in concrete environments, reducing the need for frequent replacements and minimizing construction waste. Its resistance to corrosion ensures safer structural integrity over time, lowering the risk of material failure that could pose safety hazards. By choosing alkaline resistant mesh, your projects contribute to sustainable building practices while enhancing long-term safety standards.

Choosing the Right Mesh for Your Project Needs

Alkaline resistant mesh is specifically engineered to withstand high pH environments, making it ideal for concrete reinforcement where exposure to alkalinity causes standard mesh to deteriorate rapidly. Standard mesh, while adequate for non-corrosive applications, lacks the durability to endure prolonged exposure to alkaline substances, leading to corrosion and reduced structural integrity. Choosing the right mesh depends on factors such as environmental conditions, longevity requirements, and structural load, with alkaline resistant mesh offering superior performance for projects involving concrete or highly alkaline materials.

Alkaline resistant mesh vs standard mesh Infographic

libmatt.com

libmatt.com