Screw jacks rely on a threaded screw mechanism to lift loads with precise control, making them ideal for applications requiring gradual adjustments. Bottle jacks use hydraulic pressure to lift heavier loads quickly and efficiently, providing greater lifting capacity for your automotive or industrial needs.

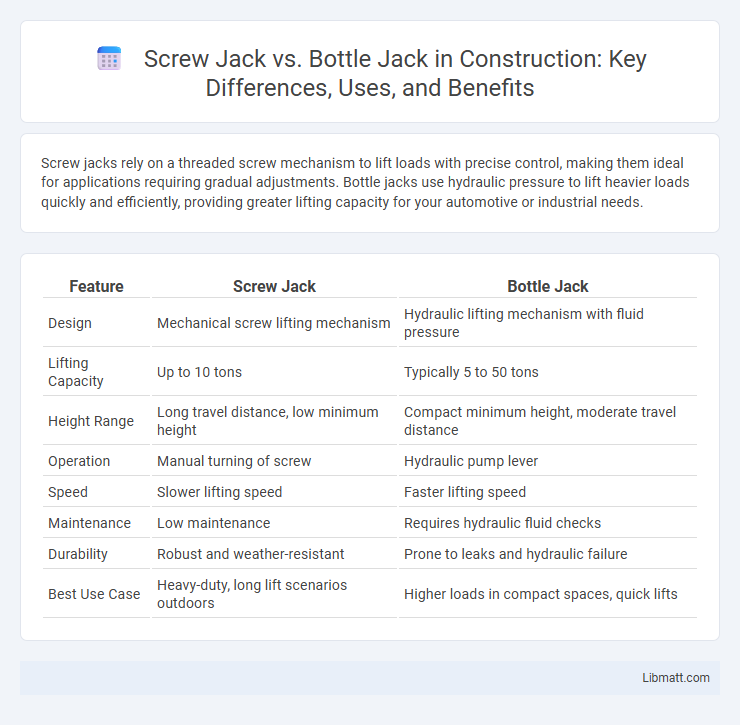

Table of Comparison

| Feature | Screw Jack | Bottle Jack |

|---|---|---|

| Design | Mechanical screw lifting mechanism | Hydraulic lifting mechanism with fluid pressure |

| Lifting Capacity | Up to 10 tons | Typically 5 to 50 tons |

| Height Range | Long travel distance, low minimum height | Compact minimum height, moderate travel distance |

| Operation | Manual turning of screw | Hydraulic pump lever |

| Speed | Slower lifting speed | Faster lifting speed |

| Maintenance | Low maintenance | Requires hydraulic fluid checks |

| Durability | Robust and weather-resistant | Prone to leaks and hydraulic failure |

| Best Use Case | Heavy-duty, long lift scenarios outdoors | Higher loads in compact spaces, quick lifts |

Introduction to Screw Jacks and Bottle Jacks

Screw jacks use a threaded screw mechanism to lift heavy loads by converting rotational force into linear motion, offering precise control and stability for applications like vehicle maintenance and industrial tasks. Bottle jacks, characterized by their compact, hydraulic design, provide powerful lifting capabilities through fluid pressure, making them ideal for quick, heavy lifting in confined spaces such as automotive repairs. Understanding the differences between these jacks helps you select the right tool based on load capacity, lifting speed, and operational convenience.

How Screw Jacks Work

Screw jacks operate by turning a lead screw, which converts rotational motion into linear lifting force, allowing precise control over heavy loads. The mechanical advantage comes from the thread pitch, enabling you to lift or hold weight steadily without power. These jacks are ideal for applications requiring slow, controlled lifting and can support heavy equipment safely.

How Bottle Jacks Operate

Bottle jacks operate using hydraulic pressure generated by a pump piston pushing fluid into a cylinder, creating force that lifts heavy loads with minimal manual effort. Their compact, vertical design houses a piston and a reservoir filled with hydraulic fluid, allowing for smooth, controlled lifting. This hydraulic mechanism enables bottle jacks to lift heavier weights more efficiently than screw jacks, which rely solely on mechanical threads for elevation.

Key Differences Between Screw Jacks and Bottle Jacks

Screw jacks use a threaded screw mechanism to lift loads, providing precise control and gradual lifting, while bottle jacks employ a hydraulic system for faster, more powerful lifting. Screw jacks are typically better suited for lighter loads and applications requiring fine adjustments, whereas bottle jacks excel at handling heavier weights with less manual effort. Understanding these key differences helps you select the right jack for your vehicle maintenance or industrial needs.

Load Capacity Comparison

Screw jacks typically have a lower load capacity compared to bottle jacks, often handling loads up to 20 tons, while bottle jacks can support much heavier loads, frequently exceeding 50 tons. The robust hydraulic mechanism of bottle jacks allows for greater lifting force with less effort, making them ideal for lifting heavier vehicles or machinery. Your choice between the two should consider the specific load capacity requirements of your lifting tasks.

Safety and Stability Considerations

Screw jacks provide enhanced safety through their self-locking mechanism, which prevents sudden lowering and offers greater stability on uneven surfaces. Bottle jacks, while compact and capable of lifting heavier loads, require careful placement and additional support to avoid tipping or slipping hazards. Your choice should prioritize the jack type that aligns with your specific stability needs and safety requirements during lifting tasks.

Applications and Best Use Cases

Screw jacks are ideal for precision lifting and gradual height adjustments in automotive repair, industrial machinery, and heavy equipment maintenance due to their mechanical advantage and stability. Bottle jacks excel in compact spaces and heavy-duty lifting scenarios such as vehicle tire changes, construction work, and emergency roadside assistance, offering greater lifting capacity with a hydraulic mechanism. Your choice depends on the specific application requirements, including load weight, space constraints, and desired lifting speed.

Portability and Ease of Use

Screw jacks offer lightweight design and simple manual operation, making them highly portable and easy to use for quick, low-lift tasks. Bottle jacks provide greater lifting capacity with a compact hydraulic mechanism but tend to be heavier and less convenient to carry. Your choice depends on whether portability or lifting power is the priority for your application.

Maintenance Requirements

Screw jacks demand regular lubrication of the screw threads and inspection for wear to ensure smooth operation and longevity. Bottle jacks require periodic checking of hydraulic fluid levels and seals to prevent leaks and maintain lifting capacity. Understanding these maintenance needs helps you choose the jack that fits your usage and upkeep preferences.

Choosing the Right Jack for Your Needs

Choosing the right jack depends on your specific lifting requirements and workspace constraints. Screw jacks offer precise, steady lifting for moderate loads and are ideal for automotive repair and mechanical applications requiring slow, controlled elevation. Bottle jacks provide higher lifting capacity with compact design, making them suitable for heavy-duty vehicles and limited space situations, where quick, powerful lifting is essential.

Screw jack vs bottle jack Infographic

libmatt.com

libmatt.com