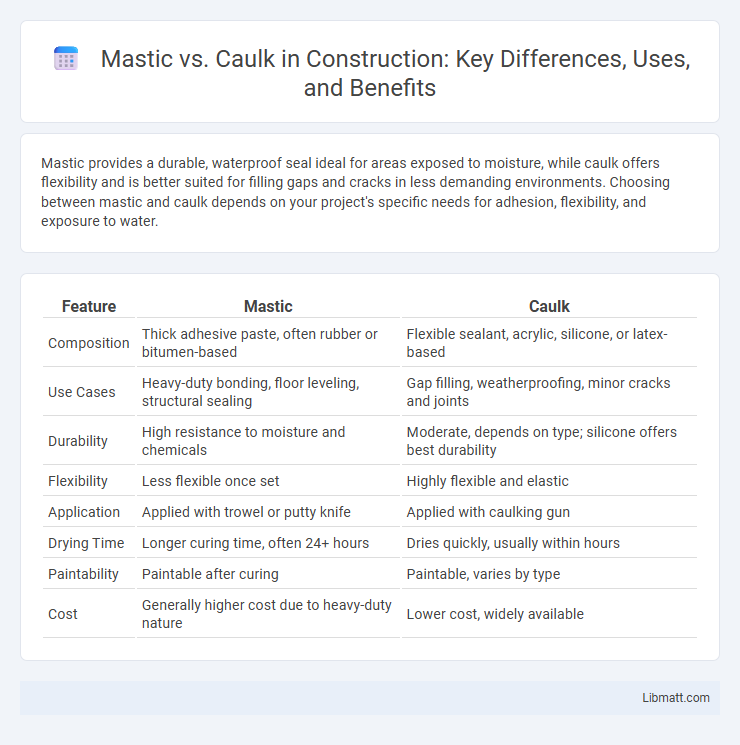

Mastic provides a durable, waterproof seal ideal for areas exposed to moisture, while caulk offers flexibility and is better suited for filling gaps and cracks in less demanding environments. Choosing between mastic and caulk depends on your project's specific needs for adhesion, flexibility, and exposure to water.

Table of Comparison

| Feature | Mastic | Caulk |

|---|---|---|

| Composition | Thick adhesive paste, often rubber or bitumen-based | Flexible sealant, acrylic, silicone, or latex-based |

| Use Cases | Heavy-duty bonding, floor leveling, structural sealing | Gap filling, weatherproofing, minor cracks and joints |

| Durability | High resistance to moisture and chemicals | Moderate, depends on type; silicone offers best durability |

| Flexibility | Less flexible once set | Highly flexible and elastic |

| Application | Applied with trowel or putty knife | Applied with caulking gun |

| Drying Time | Longer curing time, often 24+ hours | Dries quickly, usually within hours |

| Paintability | Paintable after curing | Paintable, varies by type |

| Cost | Generally higher cost due to heavy-duty nature | Lower cost, widely available |

Understanding Mastic and Caulk: Key Differences

Mastic is a thick, paste-like adhesive designed for heavy-duty sealing and bonding, often used in HVAC systems and roofing due to its strong, flexible properties. Caulk is a more versatile, pliable material ideal for filling small gaps and cracks around windows, doors, and trim to prevent air and moisture infiltration. Your choice between mastic and caulk depends on the application's durability requirements, surface type, and exposure conditions.

Common Uses for Mastic in Construction

Mastic is commonly used for sealing gaps and joints in construction due to its strong adhesive properties and flexibility, making it ideal for sealing around windows, doors, and HVAC ducts. Unlike caulk, mastic can also serve as an effective vapor barrier and is often applied in roofing and drywall installations to prevent air and moisture infiltration. Its durability and resistance to cracking make mastic a preferred choice for long-lasting seals in both interior and exterior building applications.

Typical Applications for Caulk

Caulk is typically used for sealing gaps and cracks around windows, doors, baseboards, and trim to prevent air and moisture infiltration. It adheres well to materials like wood, drywall, and metal, making it ideal for indoor and outdoor use where flexibility and paintability are important. When maintaining your home's energy efficiency and appearance, caulk provides a reliable, easy-to-apply solution for everyday sealing needs.

Pros and Cons of Mastic vs Caulk

Mastic offers superior adhesion and flexibility, making it ideal for sealing gaps in drywall and wood, but it tends to discolor and deteriorate faster when exposed to moisture. Caulk, especially silicone or acrylic types, provides excellent water resistance and durability, making it better suited for bathrooms and exteriors, although it may shrink or crack over time depending on the formulation. Choosing between mastic and caulk depends on the specific application environment and the level of exposure to moisture and temperature changes.

Adhesion and Flexibility Comparison

Mastic offers superior adhesion to porous surfaces like wood, drywall, and masonry, creating a strong, long-lasting bond that prevents moisture intrusion. Caulk provides greater flexibility, adapting well to dynamic joints and surfaces subject to expansion and contraction without cracking. The choice between mastic and caulk depends on the specific application requirements for durability and movement accommodation.

Durability and Longevity: Mastic vs Caulk

Mastic offers superior durability and longevity compared to traditional caulk, as it remains flexible and resistant to cracking, shrinking, and peeling over time. Unlike caulk, which may degrade and require frequent reapplication, mastic forms a strong, waterproof seal ideal for long-term use in both interior and exterior applications. Its ability to withstand temperature fluctuations and moisture exposure ensures prolonged performance in sealing joints and gaps.

Installation Techniques and Ease of Use

Mastic offers a thicker, more pliable consistency that allows for easier application over uneven surfaces, often requiring only a putty knife or trowel for smooth spreading. Caulk, typically supplied in a tube with a nozzle, demands a steady hand and a caulking gun to create precise, narrow beads ideal for seams and gaps. Mastic's forgiving texture makes it more user-friendly for large, irregular joints, while caulk excels in detailed, narrow areas but may require additional skill for neat, even lines.

Water and Weather Resistance: Which is Better?

Mastic offers superior water and weather resistance compared to traditional caulk, making it ideal for areas exposed to harsh environmental conditions. Its flexible polymer base allows it to withstand prolonged exposure to moisture, UV rays, and temperature fluctuations without cracking or shrinking. Caulk, while effective for sealing small gaps, often degrades faster under extreme weather, reducing its long-term durability and protective capabilities.

Cost Considerations for Mastic and Caulk

Mastic generally costs more upfront than caulk due to its thicker consistency and longer-lasting durability, making it ideal for heavy-duty sealing tasks. Caulk, being more affordable and easier to apply, suits smaller projects or quick repairs but may require more frequent replacement, increasing long-term expenses. Your choice between mastic and caulk should factor in both initial budget and maintenance frequency to optimize cost efficiency.

Choosing the Right Sealant for Your Project

Mastic offers superior flexibility and adhesion for porous surfaces like wood and masonry, making it ideal for sealing gaps that experience movement or weather exposure. Caulk provides a smoother finish and is best suited for filling smaller cracks and seams in drywall, glass, or metal surfaces where paintability and aesthetics are crucial. Selecting the right sealant depends on the material involved, expected joint movement, and exposure conditions to ensure long-lasting, effective sealing.

Mastic vs caulk Infographic

libmatt.com

libmatt.com