Lagging provides temporary or permanent structural support using timber or metal to retain soil during excavation, whereas shotcrete involves spraying concrete at high velocity onto surfaces for stabilization and reinforcement. Your choice depends on the project's needs, with lagging offering flexible excavation support and shotcrete delivering durable, fast-curing protection.

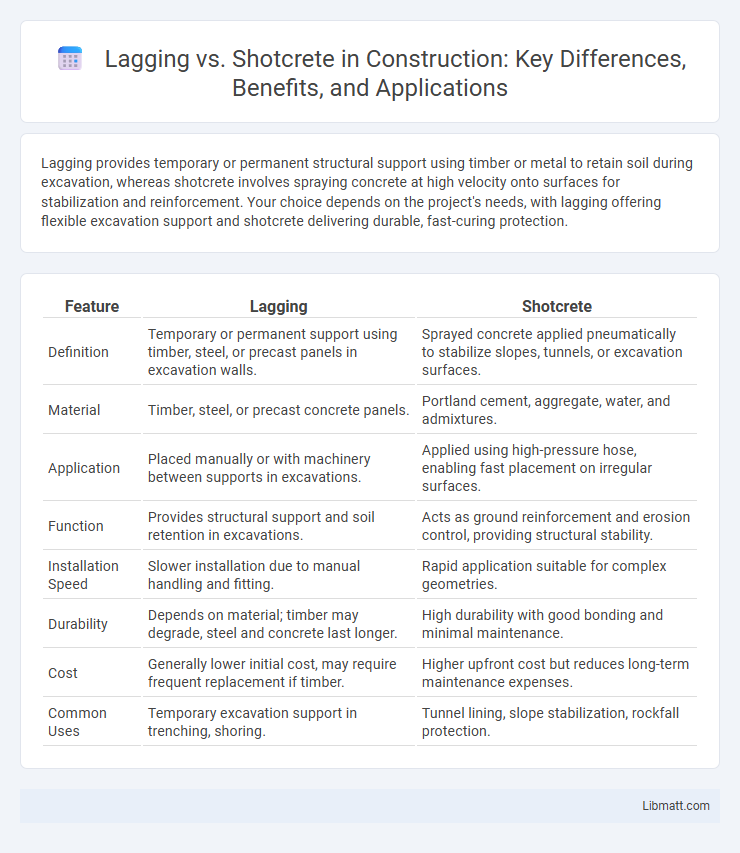

Table of Comparison

| Feature | Lagging | Shotcrete |

|---|---|---|

| Definition | Temporary or permanent support using timber, steel, or precast panels in excavation walls. | Sprayed concrete applied pneumatically to stabilize slopes, tunnels, or excavation surfaces. |

| Material | Timber, steel, or precast concrete panels. | Portland cement, aggregate, water, and admixtures. |

| Application | Placed manually or with machinery between supports in excavations. | Applied using high-pressure hose, enabling fast placement on irregular surfaces. |

| Function | Provides structural support and soil retention in excavations. | Acts as ground reinforcement and erosion control, providing structural stability. |

| Installation Speed | Slower installation due to manual handling and fitting. | Rapid application suitable for complex geometries. |

| Durability | Depends on material; timber may degrade, steel and concrete last longer. | High durability with good bonding and minimal maintenance. |

| Cost | Generally lower initial cost, may require frequent replacement if timber. | Higher upfront cost but reduces long-term maintenance expenses. |

| Common Uses | Temporary excavation support in trenching, shoring. | Tunnel lining, slope stabilization, rockfall protection. |

Introduction to Lagging and Shotcrete

Lagging and shotcrete are essential techniques in tunnel and excavation support, with lagging involving the placement of wood, steel, or concrete beams to stabilize soil or rock between support sets. Shotcrete refers to the application of sprayed concrete onto surfaces to quickly provide structural support and prevent erosion or collapse. Both methods enhance ground stability but differ in material application and reinforcement approach.

Definition and Overview of Lagging

Lagging is a construction technique used to support excavations by placing horizontal wooden or steel planks against the earth to prevent soil collapse. It acts as a temporary retaining structure in trench walls, commonly combined with soldier piles for stabilization. Shotcrete, on the other hand, involves spraying concrete onto surfaces for immediate soil support but differs fundamentally from lagging in material and application method.

Definition and Overview of Shotcrete

Shotcrete is a method of applying concrete projected at high velocity onto surfaces, enabling rapid and dense formation of structural layers, commonly used in tunneling and slope stabilization. Unlike lagging, which involves placing timber or steel plates for support, shotcrete provides immediate structural integrity and adhesion to irregular surfaces, reducing the need for additional reinforcement. This technique enhances durability and conformability, making it a preferred choice for modern construction and mining projects.

Key Differences Between Lagging and Shotcrete

Lagging primarily involves the use of timber, steel, or other materials to provide temporary or permanent support in excavation, while shotcrete is a sprayed concrete applied pneumatically for structural reinforcement. Key differences include lagging being a physical barrier or shield to prevent soil collapse, whereas shotcrete forms a solid, durable lining that bonds directly to the substrate for stabilization. Lagging installation is often faster and adaptable to changing excavation conditions, whereas shotcrete offers higher strength and long-term durability in tunnel and slope support.

Materials and Equipment Used

Lagging typically utilizes timber, steel, or prefabricated panels supported by hydraulic jacks or anchors to provide temporary earth retention, with equipment including excavation machines and drilling rigs for anchor installation. Shotcrete employs a mixture of cement, sand, water, and sometimes additives, which is pneumatically projected onto surfaces using specialized spray nozzles connected to high-pressure hoses and compressors. Both methods require specific machinery to ensure proper application and structural stability during underground construction or slope stabilization projects.

Installation Process Comparison

Lagging installation involves placing timber or steel beams against excavation walls, followed by securing them with anchors or walers, which allows for quick support but requires skilled labor and precise alignment. Shotcrete application consists of spraying concrete onto surfaces using high-pressure hoses, creating a uniform and strong lining that adapts easily to irregular shapes and reduces installation time. Shotcrete generally offers faster installation and better surface adhesion than traditional lagging, making it more suitable for complex excavation projects and uneven substrates.

Strengths and Limitations

Lagging provides robust temporary support in tunnel construction with easy installation and removal but lacks durability and long-term strength compared to shotcrete. Shotcrete offers superior structural strength, enhanced durability, and excellent adhesion to rock surfaces, making it ideal for permanent or semi-permanent ground support. However, shotcrete requires specialized equipment and skilled labor, increasing initial costs and limiting its use in highly constrained environments.

Cost Considerations

Lagging generally incurs higher labor and material costs due to the use of timber or steel boards and the need for more extensive installation processes compared to shotcrete. Shotcrete often reduces overall expenses by offering faster application times and fewer materials, which minimizes labor hours and site disruption. Evaluating project size, soil conditions, and required structural support is essential to determine the most cost-effective method between lagging and shotcrete.

Common Applications in Construction

Lagging is commonly used in temporary earth retention during excavation projects, such as trench support and tunnel construction, to stabilize soil and prevent collapses. Shotcrete is frequently applied for permanent structural support, including slope stabilization, tunnel linings, and repair of concrete surfaces due to its quick-setting and durable properties. Both methods are essential in underground construction, but lagging primarily addresses temporary support while shotcrete provides a more permanent reinforcement solution.

Choosing the Right Method for Your Project

Choosing between lagging and shotcrete depends on factors such as project scale, site conditions, and structural requirements. Lagging offers flexibility for temporary support and is well-suited for smaller excavations, while shotcrete provides rapid application and high strength for permanent linings in tunnels or large excavations. Evaluating soil stability, project timeline, and budget ensures selection of the most effective ground support method.

Lagging vs shotcrete Infographic

libmatt.com

libmatt.com