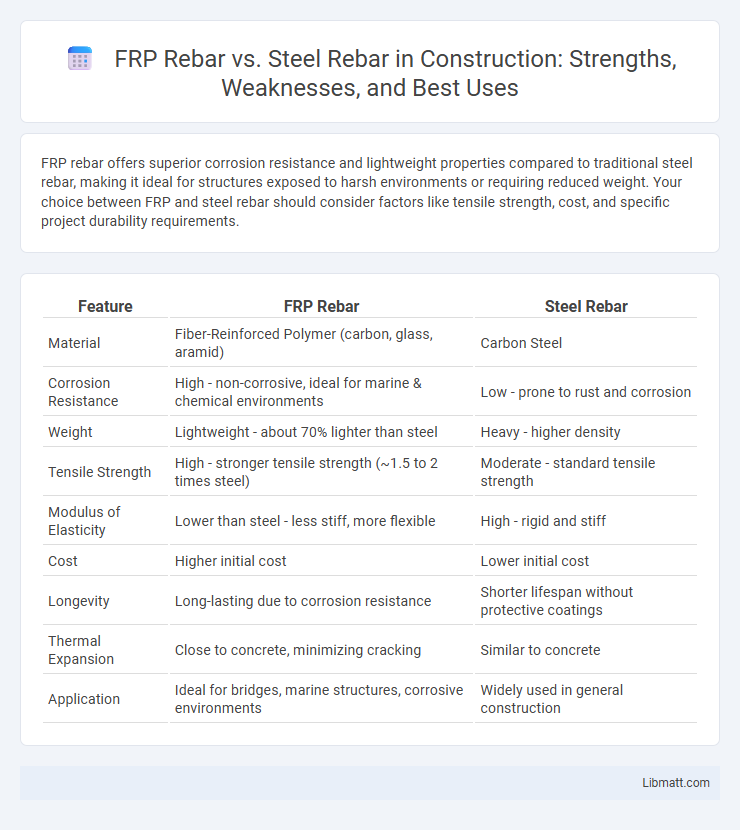

FRP rebar offers superior corrosion resistance and lightweight properties compared to traditional steel rebar, making it ideal for structures exposed to harsh environments or requiring reduced weight. Your choice between FRP and steel rebar should consider factors like tensile strength, cost, and specific project durability requirements.

Table of Comparison

| Feature | FRP Rebar | Steel Rebar |

|---|---|---|

| Material | Fiber-Reinforced Polymer (carbon, glass, aramid) | Carbon Steel |

| Corrosion Resistance | High - non-corrosive, ideal for marine & chemical environments | Low - prone to rust and corrosion |

| Weight | Lightweight - about 70% lighter than steel | Heavy - higher density |

| Tensile Strength | High - stronger tensile strength (~1.5 to 2 times steel) | Moderate - standard tensile strength |

| Modulus of Elasticity | Lower than steel - less stiff, more flexible | High - rigid and stiff |

| Cost | Higher initial cost | Lower initial cost |

| Longevity | Long-lasting due to corrosion resistance | Shorter lifespan without protective coatings |

| Thermal Expansion | Close to concrete, minimizing cracking | Similar to concrete |

| Application | Ideal for bridges, marine structures, corrosive environments | Widely used in general construction |

Introduction to FRP and Steel Rebar

FRP rebar, made from fiber-reinforced polymers such as glass, carbon, or aramid fibers, offers corrosion resistance and lightweight properties compared to traditional steel rebar. Steel rebar, typically composed of carbon steel, provides high tensile strength and durability but is prone to rust and corrosion over time. Understanding these material differences helps you select the appropriate reinforcement for concrete structures based on performance and environmental conditions.

Material Composition and Properties

FRP rebar is made from composite materials, typically consisting of fiberglass, carbon, or aramid fibers embedded in a polymer resin matrix, offering high corrosion resistance and low weight compared to steel. Steel rebar, composed of carbon steel or stainless steel, provides excellent tensile strength and ductility but is prone to corrosion when exposed to moisture and chlorides. The material properties of FRP rebar include non-magnetic behavior, high tensile strength-to-weight ratio, and resistance to chemical degradation, whereas steel rebar is valued for its well-known mechanical performance and ability to bond effectively with concrete.

Strength and Durability Comparison

FRP rebar exhibits high tensile strength, often surpassing traditional steel rebar, with values ranging from 600 MPa to over 1500 MPa depending on the fiber type, such as glass or carbon fibers. Its resistance to corrosion significantly enhances durability, making FRP rebar ideal for harsh environments like marine or chemically aggressive settings where steel rebar typically suffers from rust and deterioration. While steel rebar has excellent ductility and proven structural performance, FRP rebar provides superior longevity and reduced maintenance costs due to its non-corrosive properties and high-strength-to-weight ratio.

Corrosion Resistance: FRP vs Steel

FRP rebar offers superior corrosion resistance compared to steel rebar, making it ideal for structures exposed to harsh environments or marine conditions. Unlike steel, which corrodes when exposed to moisture and chlorides, FRP rebar is non-metallic and immune to rust, significantly extending the lifespan of reinforced concrete. Choosing FRP rebar can reduce maintenance costs and improve the durability of your infrastructure projects.

Weight and Handling Differences

FRP rebar is significantly lighter than steel rebar, typically weighing about 75% less, which greatly reduces transportation and labor costs during construction. Its lightweight nature enhances handling efficiency, allowing fewer workers to carry and install it without heavy machinery, improving on-site safety and productivity. You will find FRP rebar especially advantageous in projects requiring corrosion resistance without the burden of heavy steel reinforcement.

Installation and Workability

FRP rebar offers lighter weight and corrosion resistance, enhancing ease of handling and reducing installation time compared to traditional steel rebar, which is heavier and requires additional anti-corrosion measures. The flexibility of FRP rebar allows for easier cutting and bending on-site, improving workability in complex structures, whereas steel rebar demands specialized tools and labor. Your construction projects benefit from smoother installation processes and lower labor costs using FRP rebar without compromising structural integrity.

Cost Analysis and Lifecycle Value

FRP rebar typically has a higher initial cost compared to steel rebar but offers significant lifecycle value due to its corrosion resistance, reducing maintenance and replacement expenses over time. Steel rebar, while generally less expensive upfront, often incurs higher long-term costs because of corrosion-related deterioration, especially in harsh environments. Your investment in FRP rebar can lead to cost savings and enhanced structural longevity in projects exposed to moisture or chemicals.

Sustainability and Environmental Impact

FRP rebar offers significant sustainability advantages over traditional steel rebar by being corrosion-resistant, which reduces maintenance needs and extends the lifespan of concrete structures, thereby lowering resource consumption. Its lightweight nature leads to decreased transportation emissions and energy use during installation, further minimizing environmental impact. Unlike steel rebar, FRP is non-toxic and can be manufactured with recycled materials, contributing to a reduced carbon footprint in construction projects.

Common Applications in Construction

FRP rebar is commonly used in structures exposed to corrosive environments such as bridges, marine facilities, and wastewater treatment plants due to its high corrosion resistance and lightweight properties. Steel rebar remains the preferred choice for general construction projects like commercial buildings and residential foundations because of its high tensile strength and cost-effectiveness. Your selection between FRP rebar and steel rebar should consider the specific environmental conditions and structural requirements of the construction project.

Choosing the Right Rebar for Your Project

FRP rebar offers superior corrosion resistance and lightweight properties compared to traditional steel rebar, making it ideal for marine, chemical, and infrastructure projects exposed to harsh environments. Steel rebar provides higher tensile strength and is more cost-effective for general construction and heavy-load structures. Selecting the right rebar depends on project-specific factors such as environmental exposure, budget constraints, and structural requirements.

FRP rebar vs steel rebar Infographic

libmatt.com

libmatt.com