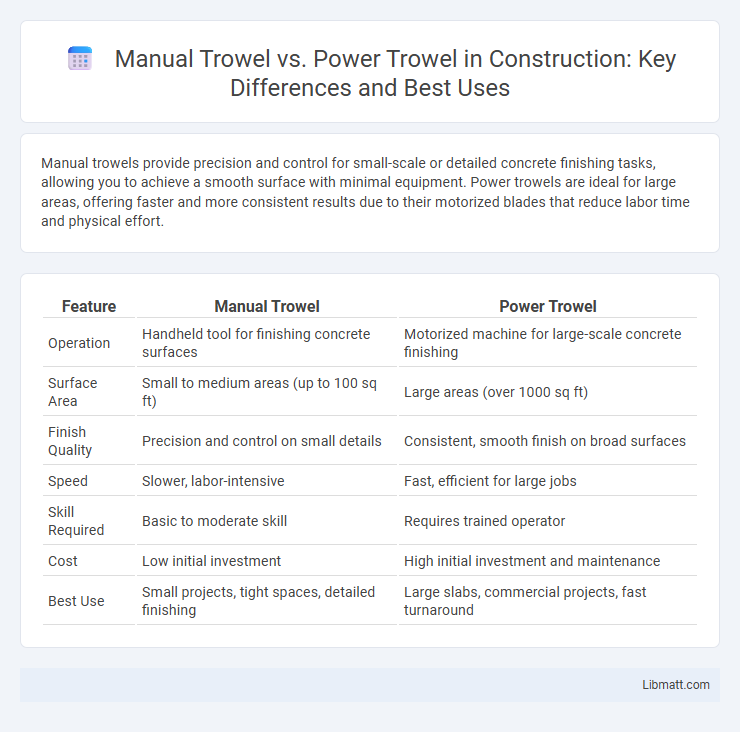

Manual trowels provide precision and control for small-scale or detailed concrete finishing tasks, allowing you to achieve a smooth surface with minimal equipment. Power trowels are ideal for large areas, offering faster and more consistent results due to their motorized blades that reduce labor time and physical effort.

Table of Comparison

| Feature | Manual Trowel | Power Trowel |

|---|---|---|

| Operation | Handheld tool for finishing concrete surfaces | Motorized machine for large-scale concrete finishing |

| Surface Area | Small to medium areas (up to 100 sq ft) | Large areas (over 1000 sq ft) |

| Finish Quality | Precision and control on small details | Consistent, smooth finish on broad surfaces |

| Speed | Slower, labor-intensive | Fast, efficient for large jobs |

| Skill Required | Basic to moderate skill | Requires trained operator |

| Cost | Low initial investment | High initial investment and maintenance |

| Best Use | Small projects, tight spaces, detailed finishing | Large slabs, commercial projects, fast turnaround |

Introduction to Manual and Power Trowels

Manual trowels are hand-operated tools used for finishing concrete surfaces, providing precise control for small to medium-sized projects. Power trowels, powered by gasoline or electric motors, offer faster and more efficient finishing on large slabs, improving productivity and surface smoothness. Understanding the differences between manual and power trowels helps optimize concrete finishing techniques based on project scale and desired surface quality.

Key Differences Between Manual and Power Trowels

Manual trowels require more physical effort and are ideal for small or detailed concrete surfaces, offering precise control but slower finishing times. Power trowels, equipped with gasoline or electric motors, provide faster, more efficient finishing for large flat surfaces by automating the smoothing process with rotating blades. The key differences include operational speed, surface area coverage, labor intensity, and suitability for project scale.

Advantages of Using a Manual Trowel

Manual trowels offer superior control and precision for detailed finishing work on concrete surfaces, allowing craftsmen to achieve a smooth and even texture. They are ideal for small to medium-sized projects where careful attention to edges and corners is necessary, providing greater maneuverability than power trowels. Manual troweling requires no electricity or fuel, making it cost-effective, environmentally friendly, and suitable for areas without power access.

Benefits of Power Trowels for Large Projects

Power trowels significantly enhance efficiency and consistency when finishing large concrete slabs, delivering smoother surfaces faster than manual troweling. Their motorized blades reduce physical strain, increasing productivity and allowing your crew to cover extensive areas with uniform quality. This equipment is essential for large-scale projects where time, durability, and finish precision are critical factors.

Surface Finish Quality: Manual vs Power Troweling

Manual troweling provides a finer surface finish with greater control over texture and detail, ideal for smaller or intricate areas requiring high precision. Power trowels offer faster coverage and consistent results on large slabs but may produce a slightly less smooth surface due to mechanical operation. The choice between manual and power troweling depends on project size, desired finish quality, and surface complexity.

Cost Comparison: Manual vs Power Trowel

Manual trowels have a significantly lower upfront cost, typically ranging from $20 to $100, making them ideal for small-scale projects and tight budgets. Power trowels, however, require an initial investment of $2,000 to $10,000 or more, but they offer increased efficiency and faster completion times for large concrete surfaces. Long-term costs also include fuel, maintenance, and operator training for power trowels, whereas manual trowels incur minimal ongoing expenses.

Efficiency and Labor Requirements

Manual trowels demand significant physical effort and time, making them less efficient for large-scale concrete finishing projects. Power trowels dramatically increase efficiency by covering extensive surface areas quickly while reducing labor intensity and fatigue. Your choice impacts project timelines and workforce allocation, with power trowels offering superior productivity for commercial or industrial concrete work.

Ideal Applications for Manual Trowels

Manual trowels are ideal for small-scale concrete projects, such as patch repairs, finishing edges, and working in tight or confined spaces where precision is critical. They offer superior control for intricate work on slabs, steps, and decorative finishes, making them perfect for homeowners, contractors, and artisans focusing on detailed craftsmanship. Manual troweling ensures smooth, high-quality surfaces in applications with limited area or when power equipment is impractical.

When to Choose a Power Trowel

Choose a power trowel for large concrete slabs exceeding 800 square feet to ensure faster finishing and a smoother surface compared to manual troweling. Power trowels provide uniform results by maintaining consistent pressure and speed, ideal for commercial or industrial projects where time efficiency is crucial. Your project benefits from reduced labor costs and enhanced durability when using a power trowel on extensive surfaces.

Final Verdict: Selecting the Right Trowel for Your Project

Manual trowels offer precise control and are ideal for small to medium-sized projects or detailed finishing work, while power trowels provide faster coverage and smoother surfaces, making them suitable for large-scale concrete projects. Budget constraints and project size heavily influence the choice; manual trowels require less upfront investment, whereas power trowels can reduce labor costs and time significantly. Selecting the right trowel depends on balancing factors like surface area, desired finish quality, and project timeline to achieve optimal results.

Manual trowel vs power trowel Infographic

libmatt.com

libmatt.com