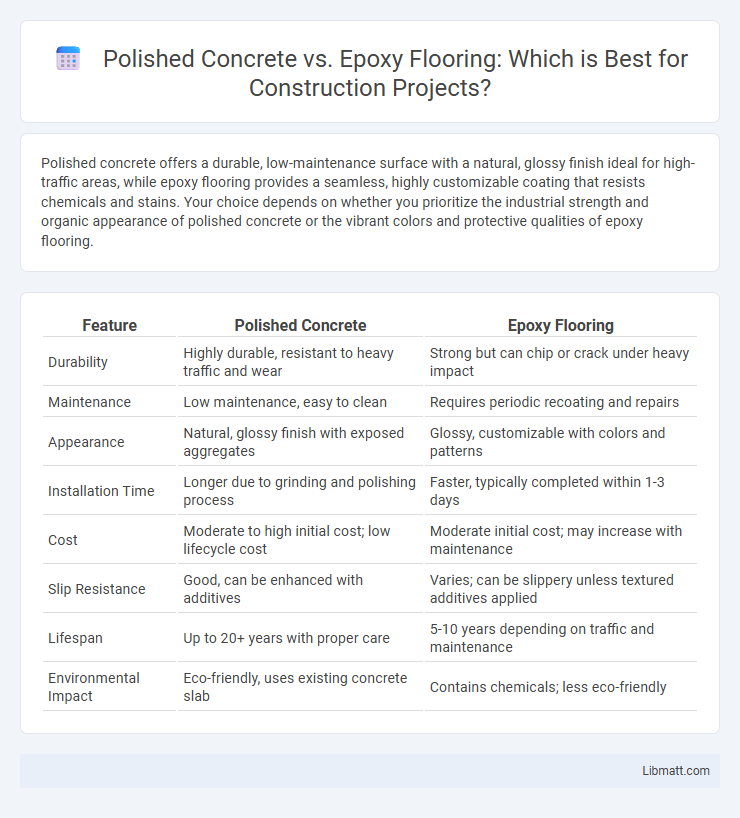

Polished concrete offers a durable, low-maintenance surface with a natural, glossy finish ideal for high-traffic areas, while epoxy flooring provides a seamless, highly customizable coating that resists chemicals and stains. Your choice depends on whether you prioritize the industrial strength and organic appearance of polished concrete or the vibrant colors and protective qualities of epoxy flooring.

Table of Comparison

| Feature | Polished Concrete | Epoxy Flooring |

|---|---|---|

| Durability | Highly durable, resistant to heavy traffic and wear | Strong but can chip or crack under heavy impact |

| Maintenance | Low maintenance, easy to clean | Requires periodic recoating and repairs |

| Appearance | Natural, glossy finish with exposed aggregates | Glossy, customizable with colors and patterns |

| Installation Time | Longer due to grinding and polishing process | Faster, typically completed within 1-3 days |

| Cost | Moderate to high initial cost; low lifecycle cost | Moderate initial cost; may increase with maintenance |

| Slip Resistance | Good, can be enhanced with additives | Varies; can be slippery unless textured additives applied |

| Lifespan | Up to 20+ years with proper care | 5-10 years depending on traffic and maintenance |

| Environmental Impact | Eco-friendly, uses existing concrete slab | Contains chemicals; less eco-friendly |

Introduction to Polished Concrete and Epoxy Flooring

Polished concrete is a durable, high-gloss surface achieved by mechanically grinding and polishing concrete slabs, enhancing both strength and aesthetic appeal. Epoxy flooring consists of a resin and hardener mixture that creates a seamless, chemical-resistant coating ideal for industrial and commercial environments. Both options offer long-lasting solutions with distinct benefits in terms of maintenance, durability, and visual finish.

Appearance and Aesthetic Versatility

Polished concrete offers a sleek, natural stone look with a glossy finish that highlights aggregate patterns and variations, providing an industrial yet modern aesthetic. Epoxy flooring delivers vibrant color options and customizable designs, including metallic and textured finishes, allowing for more creative and bold visual statements. You can achieve timeless elegance with polished concrete or dynamic, personalized styles with epoxy to fit your space's aesthetic goals.

Durability and Wear Resistance

Polished concrete boasts exceptional durability with a dense surface that withstands heavy foot traffic, impact, and abrasion, making it ideal for industrial and commercial spaces. Epoxy flooring offers superior wear resistance with a seamless, chemical-resistant coating that protects against stains, moisture, and surface wear in high-traffic or harsh environments. You can choose polished concrete for long-lasting toughness or epoxy flooring for enhanced protection and maintenance ease.

Installation Process Comparison

Polished concrete installation involves grinding, honing, and sealing the existing concrete surface, requiring specialized equipment and multiple stages to achieve a smooth, reflective finish. Epoxy flooring installation requires thorough surface preparation, including cleaning and priming, followed by the application of multiple epoxy resin layers that cure to form a durable coating. Your choice depends on desired durability, aesthetic preferences, and installation time, with polished concrete generally having a longer, more complex process compared to the quicker but more layered epoxy application.

Maintenance and Cleaning Requirements

Polished concrete requires minimal maintenance due to its durable, sealed surface that resists stains and abrasion, needing only occasional damp mopping to maintain its shine. Epoxy flooring demands more frequent cleaning to prevent surface wear and avoid buildup of dirt or chemicals that can dull its finish over time. Your choice should consider the ease of upkeep aligned with the specific traffic and usage patterns of your space.

Cost Analysis: Upfront and Long-Term

Polished concrete generally offers a lower upfront cost compared to epoxy flooring due to minimal materials and labor requirements, making it budget-friendly for large areas. Over time, polished concrete requires less maintenance and has greater durability, reducing long-term expenses, while epoxy flooring may need periodic recoating and repairs that increase costs. Your choice should consider both immediate budget constraints and future maintenance investments to ensure an optimal balance of cost and performance.

Slip Resistance and Safety Features

Polished concrete offers moderate slip resistance due to its smooth finish but can be enhanced with sealers or anti-slip additives for improved safety in wet conditions. Epoxy flooring provides superior slip resistance when textured with aggregate or anti-slip coatings, making it ideal for high-traffic or industrial areas where safety is critical. Your choice between polished concrete and epoxy should consider specific slip resistance ratings and safety standards to ensure optimal protection.

Environmental Impact and Sustainability

Polished concrete flooring boasts a lower environmental impact due to its use of existing concrete slabs, reducing the need for additional materials and minimizing waste, while epoxy flooring often relies on petrochemical-based resins that contribute to VOC emissions and disposal concerns. Polished concrete enhances energy efficiency by improving thermal mass properties that regulate indoor temperatures, contrasting with epoxy floors that may require more frequent replacement due to wear and chemical degradation. Sustainability assessments favor polished concrete for its durability, low maintenance, and use of recycled aggregates, making it a more eco-friendly flooring option compared to the synthetic nature and potential environmental hazards associated with epoxy coatings.

Ideal Applications for Each Flooring Type

Polished concrete excels in high-traffic commercial spaces, warehouses, and retail stores due to its durability, low maintenance, and natural aesthetic. Epoxy flooring is ideal for industrial settings, garages, and laboratories where chemical resistance, seamless surface, and enhanced safety features like anti-slip additives are critical. Your choice depends on the specific application requirements, with polished concrete offering a long-lasting, eco-friendly option and epoxy providing superior customization and protective properties.

Choosing the Best Option for Your Space

Polished concrete offers a durable, low-maintenance surface ideal for high-traffic areas and industrial settings, enhancing natural light with its reflective finish. Epoxy flooring provides customizable color options, superior chemical resistance, and seamless protection, making it suitable for commercial kitchens and garages. Evaluating factors like durability needs, aesthetic preferences, budget, and space function ensures the best flooring choice for your specific environment.

Polished concrete vs epoxy flooring Infographic

libmatt.com

libmatt.com