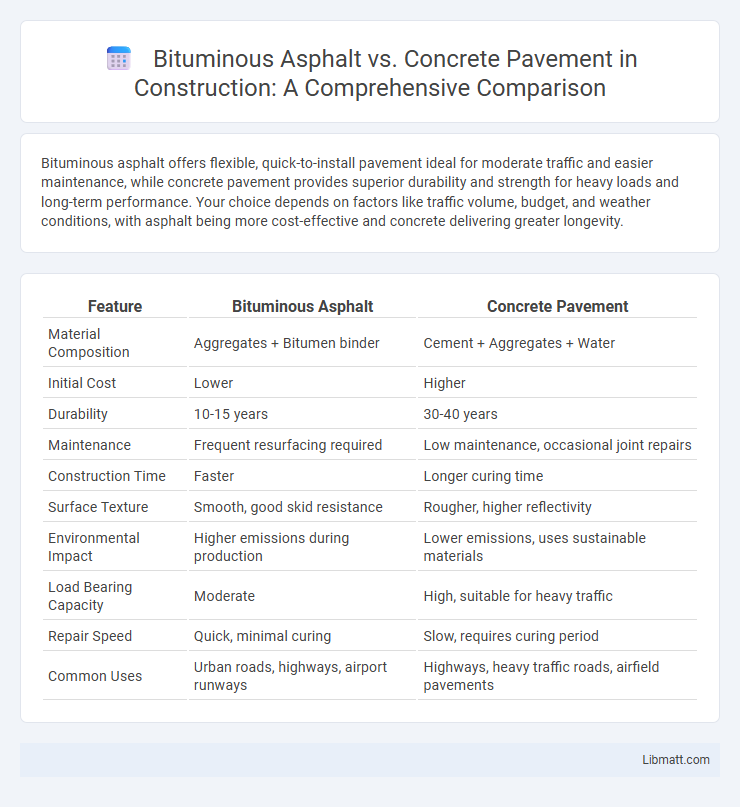

Bituminous asphalt offers flexible, quick-to-install pavement ideal for moderate traffic and easier maintenance, while concrete pavement provides superior durability and strength for heavy loads and long-term performance. Your choice depends on factors like traffic volume, budget, and weather conditions, with asphalt being more cost-effective and concrete delivering greater longevity.

Table of Comparison

| Feature | Bituminous Asphalt | Concrete Pavement |

|---|---|---|

| Material Composition | Aggregates + Bitumen binder | Cement + Aggregates + Water |

| Initial Cost | Lower | Higher |

| Durability | 10-15 years | 30-40 years |

| Maintenance | Frequent resurfacing required | Low maintenance, occasional joint repairs |

| Construction Time | Faster | Longer curing time |

| Surface Texture | Smooth, good skid resistance | Rougher, higher reflectivity |

| Environmental Impact | Higher emissions during production | Lower emissions, uses sustainable materials |

| Load Bearing Capacity | Moderate | High, suitable for heavy traffic |

| Repair Speed | Quick, minimal curing | Slow, requires curing period |

| Common Uses | Urban roads, highways, airport runways | Highways, heavy traffic roads, airfield pavements |

Introduction to Pavement Types

Bituminous asphalt pavement consists of a flexible layer made from aggregates bonded with bitumen, providing smooth surfaces ideal for roads with moderate traffic and quick repairs. Concrete pavement is a rigid structure composed of Portland cement, aggregates, and water, known for its durability and strength under heavy loads and long-term use. Your choice between these pavement types depends on factors like traffic intensity, budget, and maintenance preferences.

Bituminous Asphalt Explained

Bituminous asphalt consists of a mixture of aggregates and bitumen, a viscous, black, sticky substance derived from crude oil, which acts as a binder to hold the aggregates together in flexible pavement layers. This material provides smooth, durable surfaces that are resistant to cracking and water damage, making it ideal for highways, urban roads, and airport runways. Asphalt's ability to absorb stress and accommodate slight movements reduces maintenance costs and extends pavement lifespan compared to rigid concrete alternatives.

Concrete Pavement Overview

Concrete pavement offers exceptional durability and longevity, often lasting 30 to 40 years with minimal maintenance compared to bituminous asphalt. Its high strength and rigidity make it ideal for heavy traffic loads and harsh weather conditions, reducing the need for frequent repairs. Choosing concrete pavement for Your infrastructure ensures a cost-effective solution with enhanced structural performance and environmental benefits due to its reflective surface and recyclability.

Construction Process Comparison

Bituminous asphalt pavement involves a faster construction process due to its flexibility and ease of compaction, typically allowing for quicker project completion and early traffic access. Concrete pavement requires longer curing times and more precise placement techniques, which can extend construction duration but results in higher durability and load-bearing capacity. Your choice depends on balancing immediate usability with long-term performance and maintenance needs.

Material Composition Differences

Bituminous asphalt pavement is primarily composed of aggregates mixed with bitumen, a sticky, black, and viscous form of petroleum, offering flexibility and ease of repair. Concrete pavement consists of cement, water, aggregates, and chemical admixtures, creating a rigid surface known for high durability and resistance to heavy loads. Understanding these material composition differences helps you choose the right pavement type based on performance and maintenance requirements.

Cost Analysis: Asphalt vs Concrete

Bituminous asphalt pavement typically costs between $2 to $4 per square foot, making it more economical for initial installation compared to concrete pavement, which ranges from $4 to $10 per square foot. Asphalt offers lower upfront expenses but may require more frequent maintenance and resurfacing every 10-15 years, whereas concrete pavement, despite higher initial costs, has a longer lifespan of 30-40 years with less frequent repairs. Life-cycle cost analysis often favors concrete for heavy traffic areas due to its durability and reduced maintenance costs over time.

Durability and Lifespan

Bituminous asphalt pavement typically offers a lifespan of 15 to 20 years, with high resistance to cracking and flexibility under various weather conditions, making it suitable for heavy traffic loads. Concrete pavement, known for its exceptional durability, can last 30 to 40 years or more, with superior resistance to deformation and heavy loads but is more prone to surface cracking without proper maintenance. The choice between bituminous asphalt and concrete depends on project lifespan requirements, budget constraints, and expected traffic intensity.

Maintenance Requirements and Costs

Bituminous asphalt pavement requires more frequent maintenance, including seal coating, crack filling, and resurfacing every 8-12 years, with costs generally lower in the short term compared to concrete. Concrete pavement typically has higher initial installation costs but offers longer intervals between maintenance activities, often exceeding 20 years, reducing lifecycle expenses. Maintenance costs for asphalt average $1 to $3 per square foot over 20 years, while concrete maintenance ranges from $0.5 to $1.5 per square foot, making concrete more cost-effective over time despite higher upfront investment.

Environmental Impact Assessment

Bituminous asphalt pavement typically generates higher carbon emissions during production and laying due to the use of petroleum-based materials, whereas concrete pavement produces significant CO2 emissions primarily from cement manufacturing. The recyclability of asphalt is higher, allowing for extensive reuse and reducing environmental burden, while concrete's longer lifespan can lead to lower overall resource consumption despite challenges in recycling. Life cycle assessments reveal that concrete pavement may have a lower environmental impact over extended periods due to durability, but asphalt offers advantages in energy efficiency and reduced heat island effects in urban settings.

Best Applications and Use Cases

Bituminous asphalt is best suited for roads requiring flexibility and quick repairs, such as highways, city streets, and airport runways where frequent maintenance and heavy traffic loads occur. Concrete pavement excels in heavy-duty applications like industrial yards, bridges, and long-lasting highways, offering high durability and resistance to heavy loads and harsh weather conditions. Your choice depends on balancing upfront costs, maintenance frequency, and specific environmental demands for optimal pavement performance.

Bituminous asphalt vs concrete pavement Infographic

libmatt.com

libmatt.com