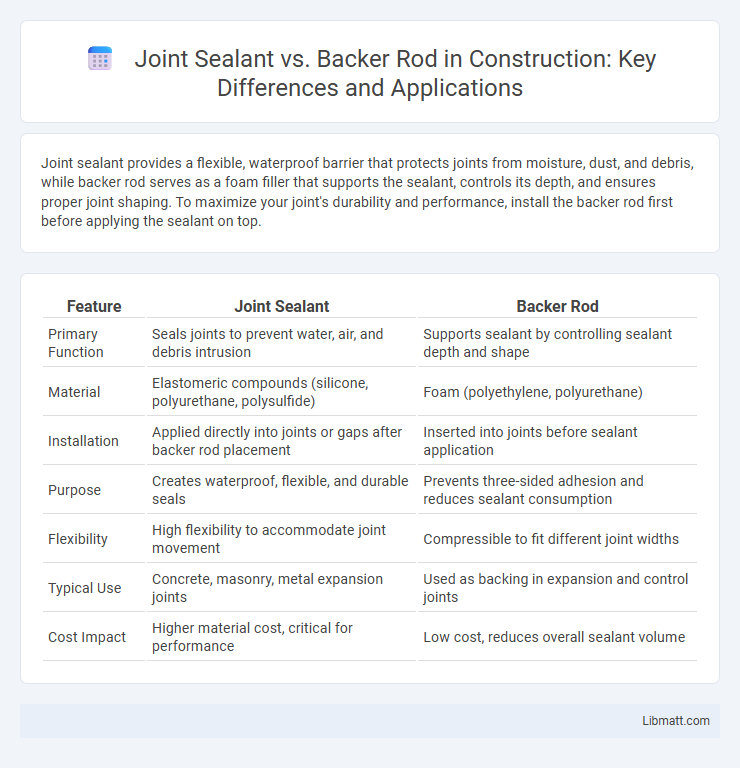

Joint sealant provides a flexible, waterproof barrier that protects joints from moisture, dust, and debris, while backer rod serves as a foam filler that supports the sealant, controls its depth, and ensures proper joint shaping. To maximize your joint's durability and performance, install the backer rod first before applying the sealant on top.

Table of Comparison

| Feature | Joint Sealant | Backer Rod |

|---|---|---|

| Primary Function | Seals joints to prevent water, air, and debris intrusion | Supports sealant by controlling sealant depth and shape |

| Material | Elastomeric compounds (silicone, polyurethane, polysulfide) | Foam (polyethylene, polyurethane) |

| Installation | Applied directly into joints or gaps after backer rod placement | Inserted into joints before sealant application |

| Purpose | Creates waterproof, flexible, and durable seals | Prevents three-sided adhesion and reduces sealant consumption |

| Flexibility | High flexibility to accommodate joint movement | Compressible to fit different joint widths |

| Typical Use | Concrete, masonry, metal expansion joints | Used as backing in expansion and control joints |

| Cost Impact | Higher material cost, critical for performance | Low cost, reduces overall sealant volume |

What is Joint Sealant?

Joint sealant is a flexible material applied to gaps or joints in construction to prevent water, air, and debris infiltration while allowing movement between surfaces. It adheres to surfaces like concrete, metal, or wood, maintaining durability and elasticity under temperature changes and structural shifts. Your choice of joint sealant impacts the longevity and effectiveness of waterproofing and protection in expansion joints or control joints.

What is a Backer Rod?

A backer rod is a flexible foam material used to fill gaps in joints before applying sealant, ensuring proper sealant depth and preventing three-sided adhesion. It provides a compressible base that supports the sealant, allowing for controlled expansion and contraction in building materials. Unlike joint sealants, which are the actual sealing compounds, backer rods serve as a backing filler that improves the durability and performance of the sealant application.

Purpose and Function of Joint Sealant

Joint sealant is designed to fill and seal gaps between building materials, preventing water, air, and debris infiltration while accommodating structural movement. Unlike backer rods, which serve as a backing material to control sealant depth and shape, joint sealants provide the primary protective barrier and adhesion. Ensuring the proper application of joint sealant enhances Your structure's durability and weather resistance.

Purpose and Function of Backer Rod

Backer rods serve as a crucial component in joint sealant applications by providing a backing that controls the depth of the sealant, allowing it to cure properly and maintain flexibility. They prevent the three-sided adhesion of the sealant, which helps in reducing stress and enhancing the durability of the joint. By filling the joint space, backer rods also aid in creating a proper sealant profile and optimize material usage.

Key Differences Between Joint Sealant and Backer Rod

Joint sealant is a flexible material applied to fill and seal gaps between building components, preventing water, air, and debris infiltration, while backer rod is a compressible foam inserted into joints to control sealant depth and provide a backing for proper sealant application. The primary difference lies in function: backer rods support and shape the sealant, enhancing its durability, whereas joint sealants create the actual seal. Understanding these key differences ensures your joints remain effectively sealed and resilient against environmental stress.

Applications: Where to Use Joint Sealant vs Backer Rod

Joint sealant is used in gaps, cracks, and joints where a flexible, weather-resistant, and waterproof seal is needed to prevent water, air, and debris infiltration in exterior and interior construction applications. Backer rod serves as a filler material inserted into wide joints or gaps beneath the sealant to control sealant depth, improve adhesion, and provide a backing for proper sealant shaping in expansion joints, concrete paving, and window frames. Together, backer rods and joint sealants optimize joint performance in construction, but backer rods alone do not provide sealing properties.

Material Types and Compatibility

Joint sealants are typically made from materials like silicone, polyurethane, polysulfide, and acrylic, chosen for their flexibility, durability, and adhesion to substrates such as concrete, metal, and glass. Backer rods, usually composed of closed-cell polyethylene or open-cell polyurethane foam, serve as a filler to control sealant depth and provide a firm backing, ensuring proper joint shape and optimal sealant performance. Compatibility between sealant and backer rod materials is crucial to prevent chemical reactions and ensure strong bonding, with polyethylene backer rods commonly preferred for use with polyurethane and silicone sealants due to their inert nature.

Installation Techniques: Joint Sealant vs Backer Rod

Joint sealant installation requires careful application with a caulking gun to ensure a smooth, continuous bead that adheres properly to the joint surfaces, providing a durable, flexible seal. Backer rod installation involves inserting a foam rod into the joint at the appropriate depth to control sealant thickness and prevent three-sided adhesion, improving sealant performance and longevity. Understanding these techniques helps you achieve optimal joint sealing by combining the backer rod as a backing material with the joint sealant on top.

Cost Comparison and Longevity

Joint sealants generally have a higher initial cost compared to backer rods, but their flexible, waterproof properties extend the lifespan of joints by preventing water infiltration and damage. Backer rods serve as a cost-effective filler material that supports sealant application and controls joint depth, optimizing sealant performance without significantly increasing expenses. Your choice between the two should consider not only upfront costs but also long-term durability and maintenance needs to achieve optimal joint integrity.

Choosing the Right Solution for Your Project

Selecting the right joint sealant or backer rod depends on the type of joint, movement expected, and environmental exposure. Joint sealants provide a flexible, waterproof barrier for expansion and control joints, while backer rods act as a backing material to control sealant depth and shape. Your project benefits when the proper combination is used to maximize durability, flexibility, and adhesion.

Joint sealant vs backer rod Infographic

libmatt.com

libmatt.com