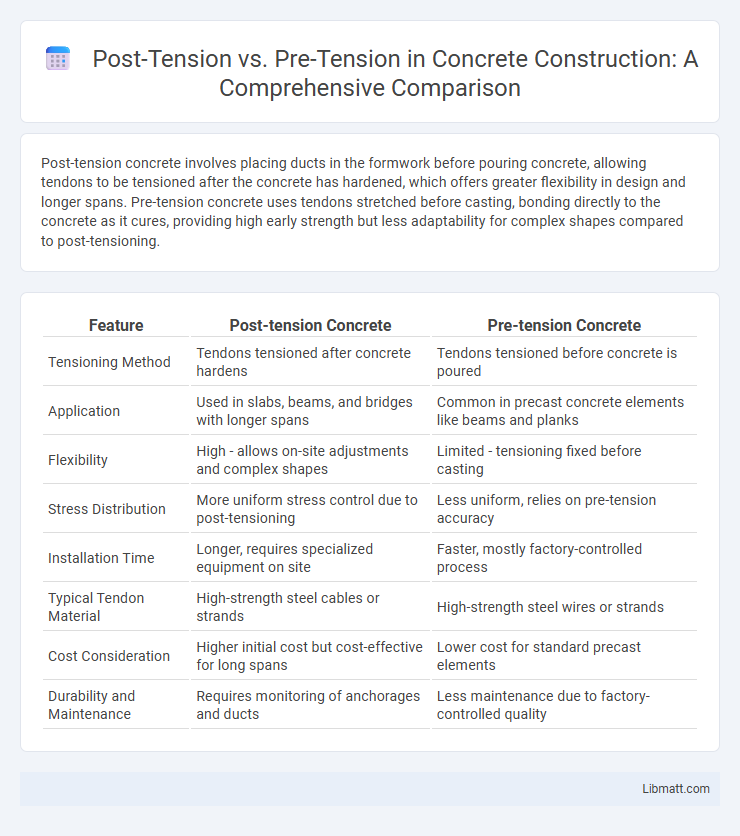

Post-tension concrete involves placing ducts in the formwork before pouring concrete, allowing tendons to be tensioned after the concrete has hardened, which offers greater flexibility in design and longer spans. Pre-tension concrete uses tendons stretched before casting, bonding directly to the concrete as it cures, providing high early strength but less adaptability for complex shapes compared to post-tensioning.

Table of Comparison

| Feature | Post-tension Concrete | Pre-tension Concrete |

|---|---|---|

| Tensioning Method | Tendons tensioned after concrete hardens | Tendons tensioned before concrete is poured |

| Application | Used in slabs, beams, and bridges with longer spans | Common in precast concrete elements like beams and planks |

| Flexibility | High - allows on-site adjustments and complex shapes | Limited - tensioning fixed before casting |

| Stress Distribution | More uniform stress control due to post-tensioning | Less uniform, relies on pre-tension accuracy |

| Installation Time | Longer, requires specialized equipment on site | Faster, mostly factory-controlled process |

| Typical Tendon Material | High-strength steel cables or strands | High-strength steel wires or strands |

| Cost Consideration | Higher initial cost but cost-effective for long spans | Lower cost for standard precast elements |

| Durability and Maintenance | Requires monitoring of anchorages and ducts | Less maintenance due to factory-controlled quality |

Introduction to Prestressed Concrete

Prestressed concrete enhances structural performance by introducing internal stresses to counteract external loads, achieved through post-tensioning or pre-tensioning techniques. Pre-tensioning involves tensioning steel tendons before concrete casting, resulting in a strong bond as concrete hardens around the stressed steel. Post-tensioning applies tension after concrete curing, allowing greater flexibility and control in your construction projects.

Fundamentals of Pre-tensioning

Pre-tensioning in concrete involves casting steel tendons in a tensioned state before pouring concrete, which bonds the concrete to the tendons upon curing. This method imparts compressive stresses to the concrete, enhancing its tensile strength and controlling cracking under load. Pre-tensioned concrete is commonly used in precast elements like beams and slabs due to efficient fabrication and early strength development.

Basics of Post-tensioning

Post-tensioning involves casting concrete around high-strength steel tendons that are tensioned after the concrete achieves sufficient strength, creating compressive forces to enhance structural performance. This technique reduces concrete cracking, allows for longer spans, and enables thinner slabs compared to traditional reinforcement methods. Post-tensioning is widely used in bridges, parking structures, and slabs-on-ground due to its flexibility and improved load-bearing capacity.

Post-tensioning vs Pre-tensioning: Key Differences

Post-tensioning involves tensioning steel tendons after concrete has been cast and gained strength, allowing for longer spans and thinner slabs compared to pre-tensioning, where tendons are stressed before concrete placement. Pre-tensioning is typically done in a precast plant enabling high-volume production with uniform quality, while post-tensioning is performed onsite to accommodate unique design requirements and reduce construction joints. The choice between post-tension and pre-tension depends on factors like structural application, project scale, and load-bearing needs, influencing durability, material efficiency, and overall cost.

Construction Process Comparison

Post-tension concrete involves casting concrete first with ducts or sleeves for high-strength steel tendons, which are tensioned after the concrete achieves sufficient strength, allowing for greater flexibility in shaping slabs and longer spans. Pre-tension concrete requires tensioning steel tendons before pouring concrete, with the tendons anchored externally and the concrete curing around them, commonly used for precast elements with faster production cycles and controlled conditions. Construction processes for post-tensioning often require on-site tensioning equipment and careful monitoring of tendon stress, while pre-tensioning primarily relies on centralized plant fabrication with consistent quality control.

Applications of Pre-tensioned Concrete

Pre-tensioned concrete is commonly used in precast elements such as beams, slabs, and railway ties where high production efficiency and quality control are possible. Its application benefits structures requiring high tensile strength and minimal deflection, such as bridge girders and parking garage floor systems. You can rely on pre-tensioned concrete for repetitive, mass-produced components with consistent structural performance.

Applications of Post-tensioned Concrete

Post-tensioned concrete is widely used in applications requiring long spans and reduced structural thickness, such as bridges, parking structures, and high-rise buildings. It offers enhanced load-bearing capacity and crack control compared to pre-tensioned concrete, making it ideal for complex architectural designs and heavy load conditions. You can maximize structural efficiency and durability by choosing post-tensioning for projects needing flexibility in shape and size.

Advantages and Disadvantages of Each Method

Post-tension concrete offers superior flexibility in construction with reduced slab thickness and longer spans but requires specialized on-site tensioning equipment, increasing labor complexity. Pre-tension concrete delivers high early strength and is ideal for precast elements, though it limits design adaptability due to tensioning before casting and demands transport of heavy precast components. Understanding your project's scale and site conditions helps determine whether the controlled environment of pre-tensioning or the adaptable nature of post-tensioning better suits your structural needs.

Cost and Efficiency Considerations

Post-tension concrete generally offers higher cost-efficiency for long-span structures due to reduced material usage and faster construction times, despite higher initial labor costs for specialized tensioning equipment. Pre-tension concrete is often more economical for mass-produced components like beams and slabs, benefiting from established, automated manufacturing processes and lower labor intensity on-site. Project scale and structural requirements crucially impact the choice, with post-tensioning favored for complex, large-scale projects demanding optimized material performance.

Choosing the Right Technique for Your Project

Selecting the appropriate concrete tensioning method depends on project requirements such as structural load, span length, and construction timeline. Post-tensioning offers flexibility for longer spans and complex designs by applying tension after concrete curing, while pre-tensioning is ideal for controlled factory environments and repetitive elements. Evaluating factors like site conditions, cost efficiency, and desired performance ensures the optimal balance between durability and construction speed.

Post-tension vs Pre-tension (concrete) Infographic

libmatt.com

libmatt.com