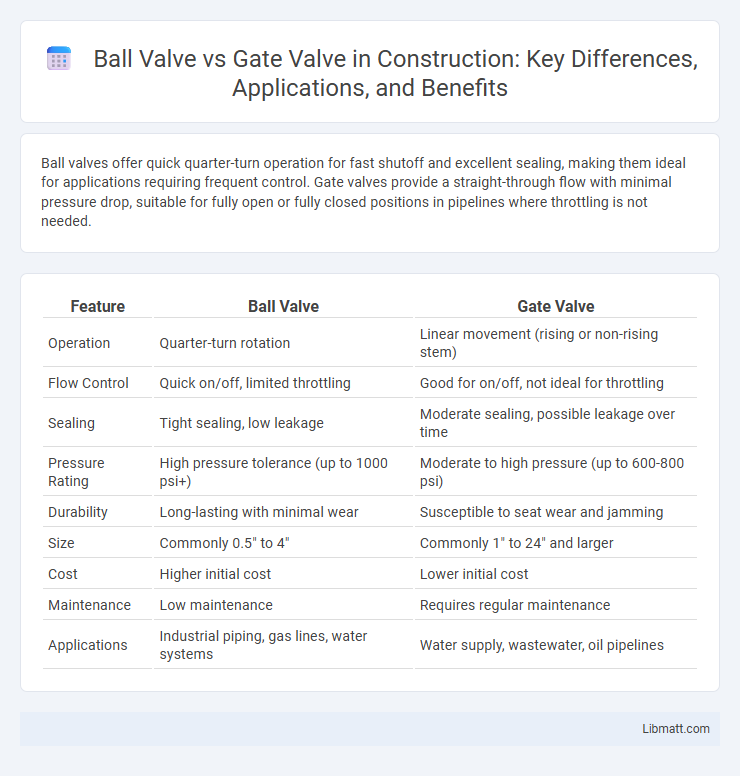

Ball valves offer quick quarter-turn operation for fast shutoff and excellent sealing, making them ideal for applications requiring frequent control. Gate valves provide a straight-through flow with minimal pressure drop, suitable for fully open or fully closed positions in pipelines where throttling is not needed.

Table of Comparison

| Feature | Ball Valve | Gate Valve |

|---|---|---|

| Operation | Quarter-turn rotation | Linear movement (rising or non-rising stem) |

| Flow Control | Quick on/off, limited throttling | Good for on/off, not ideal for throttling |

| Sealing | Tight sealing, low leakage | Moderate sealing, possible leakage over time |

| Pressure Rating | High pressure tolerance (up to 1000 psi+) | Moderate to high pressure (up to 600-800 psi) |

| Durability | Long-lasting with minimal wear | Susceptible to seat wear and jamming |

| Size | Commonly 0.5" to 4" | Commonly 1" to 24" and larger |

| Cost | Higher initial cost | Lower initial cost |

| Maintenance | Low maintenance | Requires regular maintenance |

| Applications | Industrial piping, gas lines, water systems | Water supply, wastewater, oil pipelines |

Introduction to Ball Valves and Gate Valves

Ball valves feature a spherical disc that controls flow through a quarter-turn rotation, providing quick shutoff and reliable sealing in various industrial applications. Gate valves use a flat or wedge-shaped gate that moves vertically to start or stop flow, ideal for on/off control but slower operation. Both valve types are essential in pipeline systems, with ball valves preferred for tight shutoff and gate valves for minimal pressure drop.

Key Differences Between Ball and Gate Valves

Ball valves provide quick quarter-turn operation for on/off control, while gate valves require multiple turns to fully open or close, making them slower to operate. Ball valves offer tight sealing with minimal leakage, suitable for high-pressure applications, whereas gate valves are better for regulating flow in low-pressure systems but may allow some leakage. The compact design of ball valves makes them ideal for space-constrained installations, unlike the larger, bulkier gate valves commonly used in pipelines.

Design and Structure Comparison

Ball valves feature a spherical disc with a hole that aligns with the flow when open, providing quick quarter-turn operation and tight sealing. Gate valves use a flat or wedge-shaped gate that moves vertically to block or allow flow, offering minimal pressure drop but slower operation. Your choice depends on the need for fast shut-off and durability in ball valves or precise flow control with gate valves in larger pipelines.

How Ball and Gate Valves Operate

Ball valves operate using a rotary ball with a bore that aligns with the flow path when open, allowing quick quarter-turn operation to start or stop fluid flow. Gate valves function by lifting a gate or wedge vertically out of the flow path, providing a linear motion that enables precise throttling and full flow control. Ball valves excel in fast shut-off applications, while gate valves offer minimal pressure drop when fully open, making each suitable for different flow regulation needs.

Flow Control Capabilities

Ball valves provide precise flow control with quick quarter-turn operation, making them ideal for applications requiring fast shutoff and minimal pressure drop. Gate valves offer gradual flow regulation but are better suited for on/off control in systems where flow changes are less frequent. Your choice depends on the need for rapid flow adjustment or robust isolation performance.

Common Applications of Ball vs Gate Valves

Ball valves are commonly used in applications requiring quick shutoff and high-pressure control, such as oil and gas pipelines, chemical processing, and water treatment systems. Gate valves are preferred in systems where minimal pressure drop and full flow capacity are essential, including water supply networks, wastewater treatment, and steam applications. Both valve types serve critical roles in industrial fluid control, with ball valves excelling in tight sealing and gate valves favored for regulating large flow volumes.

Durability and Maintenance Requirements

Ball valves offer superior durability due to their robust design and resistance to wear, requiring minimal maintenance over time. Gate valves, while effective for on/off control, have more moving parts that can degrade, leading to higher maintenance demands and potential leaks. Choosing a ball valve can help reduce your maintenance costs and ensure long-term reliability in various industrial applications.

Installation and Cost Considerations

Ball valves typically offer easier installation due to their compact design and versatile mounting options, reducing labor time and costs. Gate valves, often larger and bulkier, may require more space and support, increasing installation complexity and expense. Choosing the right valve for your system balances upfront costs against long-term maintenance and operational efficiency.

Advantages and Disadvantages Overview

Ball valves offer quick shutoff and reliable sealing with low pressure drop, making them ideal for applications requiring frequent operation and tight shutoff; however, their limited throttling capability and higher cost can be drawbacks. Gate valves provide a straight-through flow with minimal pressure loss and are well-suited for on/off control in large pipe diameters, but they operate slower and can suffer from seat wear and leakage over time. Choosing between ball and gate valves depends on factors such as flow control precision, frequency of use, maintenance requirements, and system pressure conditions.

Choosing the Right Valve for Your Needs

Ball valves offer quick shutoff and precise flow control, ideal for applications requiring reliable sealing and frequent operation. Gate valves provide minimal pressure drop and are better suited for fully open or fully closed positions in pipelines with low flow resistance needs. Assess your system's pressure, flow requirements, and maintenance preferences to determine which valve best fits your specific application.

Ball valve vs gate valve Infographic

libmatt.com

libmatt.com