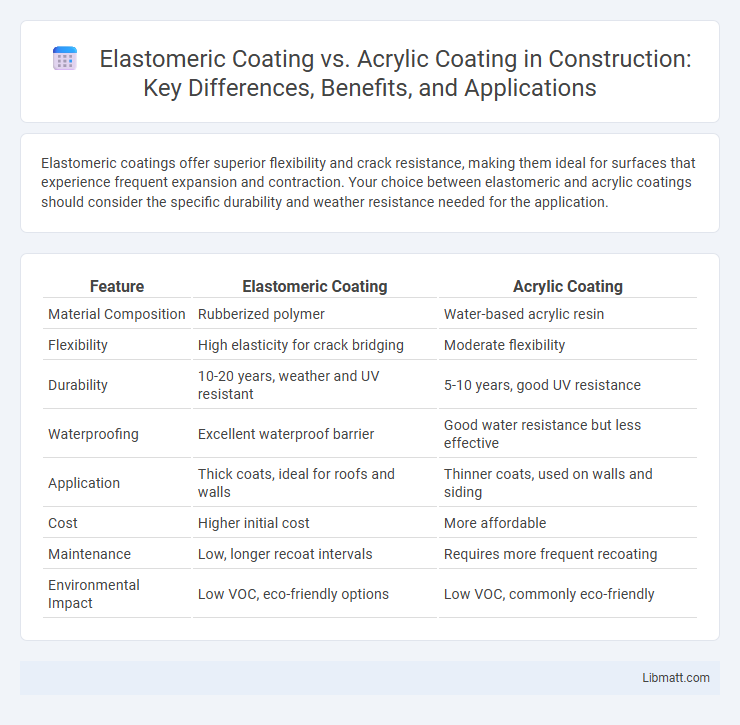

Elastomeric coatings offer superior flexibility and crack resistance, making them ideal for surfaces that experience frequent expansion and contraction. Your choice between elastomeric and acrylic coatings should consider the specific durability and weather resistance needed for the application.

Table of Comparison

| Feature | Elastomeric Coating | Acrylic Coating |

|---|---|---|

| Material Composition | Rubberized polymer | Water-based acrylic resin |

| Flexibility | High elasticity for crack bridging | Moderate flexibility |

| Durability | 10-20 years, weather and UV resistant | 5-10 years, good UV resistance |

| Waterproofing | Excellent waterproof barrier | Good water resistance but less effective |

| Application | Thick coats, ideal for roofs and walls | Thinner coats, used on walls and siding |

| Cost | Higher initial cost | More affordable |

| Maintenance | Low, longer recoat intervals | Requires more frequent recoating |

| Environmental Impact | Low VOC, eco-friendly options | Low VOC, commonly eco-friendly |

Introduction to Elastomeric and Acrylic Coatings

Elastomeric coatings are highly flexible, waterproof sealants designed to expand and contract with surface movement, making them ideal for exterior walls and roofs prone to cracking. Acrylic coatings, composed of water-based polymers, provide a durable, UV-resistant protective layer that enhances surface appearance and offers moderate flexibility. Both coatings serve as protective barriers, yet elastomeric coatings excel in waterproofing and crack bridging, while acrylic coatings are favored for ease of application and color retention.

Composition and Chemical Properties

Elastomeric coatings consist primarily of synthetic rubber polymers like styrene-butadiene or neoprene, offering high elasticity and waterproofing through superior flexibility and crack-bridging capability. Acrylic coatings are water-based polymers made from acrylic acid and its derivatives, providing excellent UV resistance, quick drying, and color retention but less flexibility compared to elastomeric options. The chemical structure of elastomeric coatings allows for significant elongation and recovery, whereas acrylic coatings emphasize durability and resistance to environmental degradation through cross-linked polymer chains.

Key Performance Differences

Elastomeric coating offers superior elasticity and crack-bridging capabilities, making it ideal for surfaces prone to movement and temperature fluctuations, while acrylic coating provides excellent UV resistance and color retention. Elastomeric coatings typically have higher thickness and durability, enhancing waterproofing performance, whereas acrylic coatings dry faster and allow for easier application and clean-up. Your choice depends on the specific demands of substrate flexibility and environmental exposure, with elastomeric ideal for extreme conditions and acrylic suited for moderate climates.

Waterproofing Capabilities

Elastomeric coating offers superior waterproofing capabilities due to its thick, flexible composition that can bridge hairline cracks and withstand extreme weather conditions. Acrylic coating provides good water resistance but may not perform as well in areas with significant temperature fluctuations or heavy rainfall. Choosing elastomeric coating can enhance your surface's durability by creating a more effective barrier against water penetration.

Flexibility and Crack Bridging

Elastomeric coatings offer superior flexibility and crack-bridging capabilities compared to acrylic coatings, making them ideal for surfaces prone to movement or thermal expansion. Their ability to stretch and return to original shape helps seal hairline cracks and prevents water infiltration effectively. Your choice of elastomeric coating ensures long-lasting protection where flexibility is critical.

UV and Weather Resistance

Elastomeric coatings offer superior UV and weather resistance due to their flexibility and ability to expand and contract with surface movements, preventing cracks and damage over time. Acrylic coatings provide good UV resistance but may degrade faster under extreme weather conditions compared to elastomeric options. For long-term protection against sun exposure and harsh climates, elastomeric coatings are generally more durable and effective.

Application Methods and Surface Preparation

Elastomeric coatings typically require thorough surface cleaning and priming to ensure proper adhesion and flexibility on substrates, often applied using rollers, brushes, or airless sprayers for uniform coverage. Acrylic coatings demand similarly clean, dry surfaces but are more forgiving with minor surface imperfections and are commonly applied with brushes or spray equipment, emphasizing good ventilation and temperature control during application. Both coatings benefit from meticulous surface preparation involving removal of dirt, chalk, and mildew to maximize adhesion and longevity.

Longevity and Maintenance Requirements

Elastomeric coatings provide superior longevity compared to acrylic coatings due to their enhanced flexibility and resistance to cracking, often lasting up to 20 years with minimal maintenance. Acrylic coatings typically require more frequent reapplication, generally every 5 to 10 years, due to their lower elasticity and susceptibility to weathering. Maintenance for elastomeric coatings is usually limited to routine cleaning, while acrylic coatings demand more frequent inspections and touch-ups to prevent damage and prolong lifespan.

Cost Comparison and Value for Money

Elastomeric coatings generally have a higher initial cost compared to acrylic coatings, but they offer superior durability and waterproofing, which can reduce long-term maintenance expenses. Acrylic coatings are more budget-friendly upfront and provide decent protection but may require more frequent reapplications, increasing overall costs over time. Investing in elastomeric coatings often results in better value for money due to their extended lifespan and enhanced resistance to weathering and cracking.

Choosing the Right Coating for Your Project

Elastomeric coating offers superior flexibility and waterproofing, making it ideal for surfaces prone to cracks or movement, while acrylic coating provides excellent UV resistance and a more affordable option for less demanding environments. Your choice depends on factors such as climate exposure, surface conditions, and budget constraints. Prioritizing elastomeric for durability or acrylic for cost-effectiveness ensures optimal protection and longevity for your project.

Elastomeric coating vs acrylic coating Infographic

libmatt.com

libmatt.com