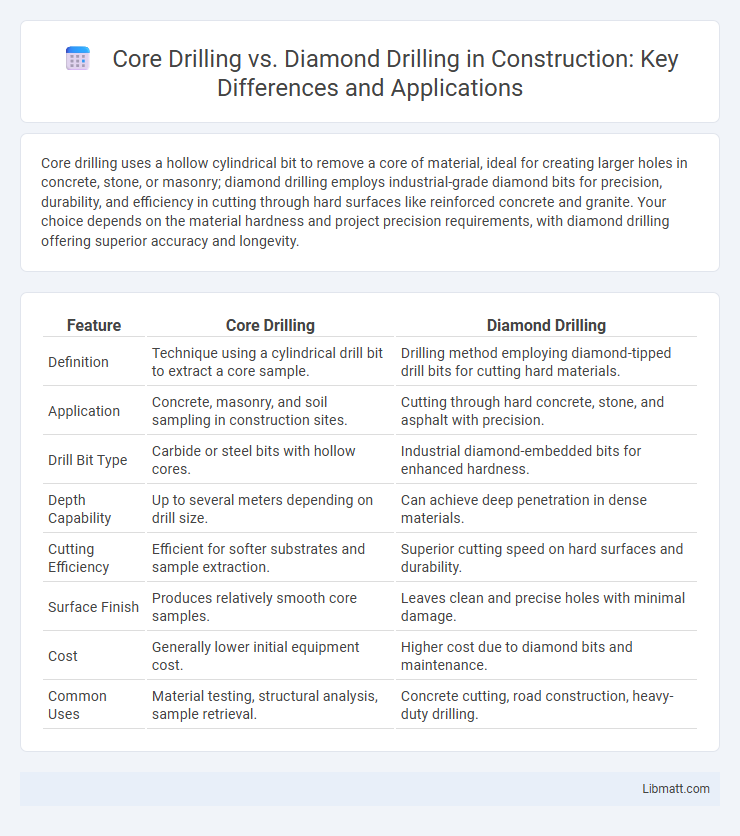

Core drilling uses a hollow cylindrical bit to remove a core of material, ideal for creating larger holes in concrete, stone, or masonry; diamond drilling employs industrial-grade diamond bits for precision, durability, and efficiency in cutting through hard surfaces like reinforced concrete and granite. Your choice depends on the material hardness and project precision requirements, with diamond drilling offering superior accuracy and longevity.

Table of Comparison

| Feature | Core Drilling | Diamond Drilling |

|---|---|---|

| Definition | Technique using a cylindrical drill bit to extract a core sample. | Drilling method employing diamond-tipped drill bits for cutting hard materials. |

| Application | Concrete, masonry, and soil sampling in construction sites. | Cutting through hard concrete, stone, and asphalt with precision. |

| Drill Bit Type | Carbide or steel bits with hollow cores. | Industrial diamond-embedded bits for enhanced hardness. |

| Depth Capability | Up to several meters depending on drill size. | Can achieve deep penetration in dense materials. |

| Cutting Efficiency | Efficient for softer substrates and sample extraction. | Superior cutting speed on hard surfaces and durability. |

| Surface Finish | Produces relatively smooth core samples. | Leaves clean and precise holes with minimal damage. |

| Cost | Generally lower initial equipment cost. | Higher cost due to diamond bits and maintenance. |

| Common Uses | Material testing, structural analysis, sample retrieval. | Concrete cutting, road construction, heavy-duty drilling. |

Introduction to Core Drilling and Diamond Drilling

Core drilling utilizes a hollow drill bit to extract cylindrical samples of rock, concrete, or soil for geological analysis and construction purposes. Diamond drilling employs industrial-grade diamond-coated bits to penetrate hard materials, enabling precise and efficient core sampling in mining and engineering projects. Both methods are essential for obtaining intact core specimens, with diamond drilling favored for extreme hardness and core drilling valued for versatile applications.

What is Core Drilling?

Core drilling is a precise method used to extract cylindrical samples from concrete, rock, or other hard materials for analysis or testing purposes. It employs a hollow, diamond-embedded drill bit to cut through tough surfaces while preserving the integrity of the core sample. You can rely on core drilling to obtain accurate subsurface information crucial for construction, geotechnical studies, and material quality assessment.

What is Diamond Drilling?

Diamond drilling uses a drill bit embedded with industrial-grade diamonds to cut through hard materials like concrete, rock, and asphalt with precision and minimal damage. This method is highly effective for extracting cylindrical core samples in geological surveys, mining exploration, and construction projects. Compared to traditional core drilling, diamond drilling offers greater accuracy, faster penetration, and enhanced durability, making it the preferred choice for demanding applications.

Key Differences Between Core Drilling and Diamond Drilling

Core drilling uses a hollow drill bit to extract cylindrical rock samples for geological analysis, while diamond drilling employs a drill bit embedded with industrial diamonds to penetrate hard rock with high precision. Diamond drilling offers superior durability and efficiency in extreme conditions, making it ideal for mining and construction projects requiring detailed subsurface data. Core drilling primarily focuses on obtaining intact samples, whereas diamond drilling emphasizes cutting power and speed.

Applications of Core Drilling

Core drilling is primarily used for extracting cylindrical samples from concrete, rock, or soil to analyze material properties and structural integrity in construction and geological surveys. This technique is essential for creating precise openings for plumbing, electrical conduits, and HVAC installations in buildings, providing clean, accurate holes without damaging surrounding materials. Your projects benefit from core drilling's ability to deliver detailed subsurface information, ensuring safer and more efficient designs.

Applications of Diamond Drilling

Diamond drilling is primarily used in geological exploration, mining, and construction for extracting precise core samples from hard rock formations. Its high cutting efficiency and durability make it essential for analyzing mineral deposits and assessing subsurface conditions accurately. You benefit from its ability to provide detailed, uncontaminated core samples critical for resource evaluation and structural integrity assessments.

Advantages of Core Drilling

Core drilling offers precise cylindrical samples essential for geological analysis and construction quality assurance. Its ability to extract intact cores preserves the structural integrity of the material, enabling accurate assessment of composition and stratification. You benefit from efficient penetration in hard substrates, reducing project time while ensuring minimal damage to surrounding structures.

Advantages of Diamond Drilling

Diamond drilling offers unparalleled precision and efficiency when extracting core samples from hard rock formations due to its industrial-grade diamond-tipped drill bits. This method minimizes sample contamination and damage, providing high-quality, intact cores essential for accurate geological analysis. Your projects benefit from faster drilling speeds and extended bit life, reducing downtime and overall operational costs compared to traditional core drilling techniques.

Choosing the Right Drilling Method

Choosing the right drilling method depends on the material hardness and project requirements, with core drilling ideal for extracting cylindrical samples from concrete or rock, and diamond drilling preferred for precision cuts in hard surfaces such as granite or reinforced concrete. Core drilling uses a hollow drill bit to remove a core sample, which helps assess the internal structure, while diamond drilling employs industrial-grade diamond-tipped bits for smooth, accurate holes with minimal damage. Evaluating factors like drill bit durability, hole diameter, and project scale ensures optimal efficiency and cost-effectiveness between core and diamond drilling techniques.

Conclusion: Core Drilling vs Diamond Drilling

Core drilling and diamond drilling both provide precise cylindrical samples from various materials, but diamond drilling offers superior cutting efficiency and durability due to the hardness of diamond bits. Core drilling is generally more cost-effective for softer materials and less demanding projects, while diamond drilling excels in hard rock or reinforced concrete environments requiring high accuracy and longer tool life. Selecting between core drilling and diamond drilling depends on material hardness, project budget, and precision requirements.

Core drilling vs Diamond drilling Infographic

libmatt.com

libmatt.com