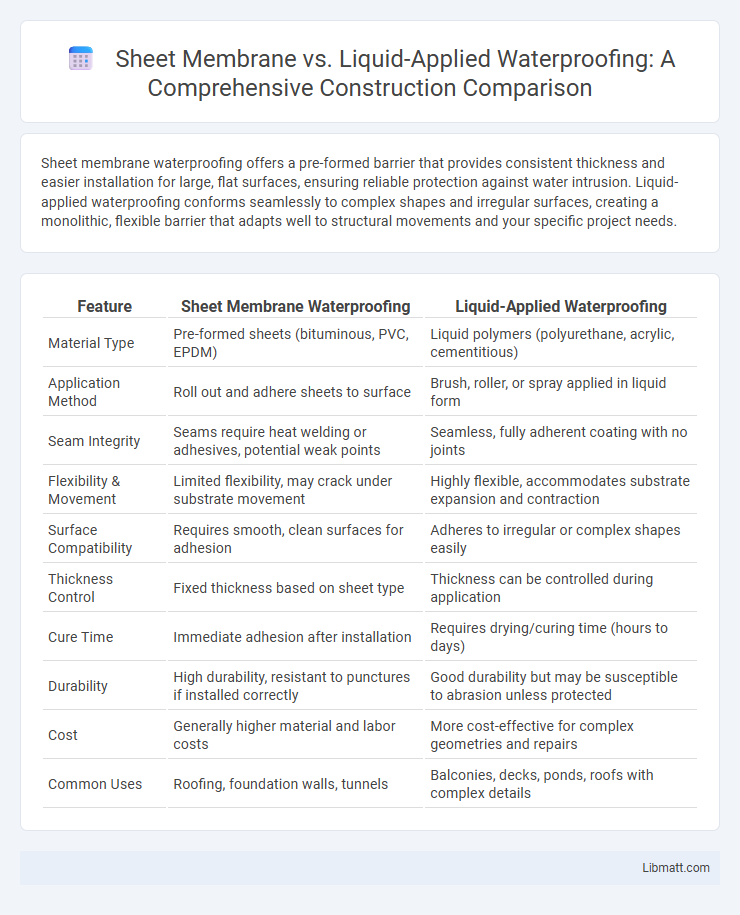

Sheet membrane waterproofing offers a pre-formed barrier that provides consistent thickness and easier installation for large, flat surfaces, ensuring reliable protection against water intrusion. Liquid-applied waterproofing conforms seamlessly to complex shapes and irregular surfaces, creating a monolithic, flexible barrier that adapts well to structural movements and your specific project needs.

Table of Comparison

| Feature | Sheet Membrane Waterproofing | Liquid-Applied Waterproofing |

|---|---|---|

| Material Type | Pre-formed sheets (bituminous, PVC, EPDM) | Liquid polymers (polyurethane, acrylic, cementitious) |

| Application Method | Roll out and adhere sheets to surface | Brush, roller, or spray applied in liquid form |

| Seam Integrity | Seams require heat welding or adhesives, potential weak points | Seamless, fully adherent coating with no joints |

| Flexibility & Movement | Limited flexibility, may crack under substrate movement | Highly flexible, accommodates substrate expansion and contraction |

| Surface Compatibility | Requires smooth, clean surfaces for adhesion | Adheres to irregular or complex shapes easily |

| Thickness Control | Fixed thickness based on sheet type | Thickness can be controlled during application |

| Cure Time | Immediate adhesion after installation | Requires drying/curing time (hours to days) |

| Durability | High durability, resistant to punctures if installed correctly | Good durability but may be susceptible to abrasion unless protected |

| Cost | Generally higher material and labor costs | More cost-effective for complex geometries and repairs |

| Common Uses | Roofing, foundation walls, tunnels | Balconies, decks, ponds, roofs with complex details |

Introduction to Waterproofing Solutions

Sheet membrane waterproofing involves pre-formed sheets made from materials like bitumen or rubber that create a durable, consistent barrier against water intrusion. Liquid-applied waterproofing uses fluid polymers that cure to form a seamless, flexible membrane ideal for irregular surfaces and detailed areas. Your choice depends on project specifics such as substrate type, application complexity, and desired longevity of the waterproofing system.

What is Sheet Membrane Waterproofing?

Sheet membrane waterproofing involves applying pre-formed sheets made of materials like rubberized asphalt or modified bitumen directly onto surfaces to create a durable, impermeable barrier against water infiltration. These membranes provide consistent thickness and high resistance to punctures and UV exposure, making them ideal for foundational and below-grade waterproofing applications. Their factory-controlled manufacturing ensures reliable quality and performance compared to liquid-applied alternatives.

What is Liquid-Applied Waterproofing?

Liquid-applied waterproofing is a seamless, flexible membrane formed by applying a liquid coating directly onto surfaces, creating a watertight barrier. This method conforms to complex shapes and penetrations, ensuring comprehensive coverage on roofs, basements, and balconies. The liquid compounds, often polyurethane or elastomeric polymers, cure to form a durable, crack-resistant layer ideal for dynamic building structures.

Key Differences Between Sheet Membrane and Liquid-Applied Waterproofing

Sheet membrane waterproofing consists of prefabricated, flexible sheets made from materials like bitumen, rubber, or PVC that provide a consistent barrier against moisture. Liquid-applied waterproofing involves applying a seamless, elastomeric coating that cures to form a protective layer, allowing it to conform to complex shapes and details. Your choice depends on factors like surface complexity, installation speed, and the need for joints or seams, as sheet membranes require careful seam sealing while liquid systems offer uniform coverage without seams.

Installation Process: Sheet Membrane vs Liquid-Applied

Sheet membrane waterproofing involves pre-fabricated rolls that are unrolled and adhered to surfaces with adhesives or heat, providing a uniform barrier that requires precise measurement and cutting during installation. Liquid-applied waterproofing, on the other hand, is applied as a fluid coating that cures to form a seamless, flexible membrane, allowing it to conform easily to complex shapes and details. Your choice depends on factors like surface type, project complexity, and desired durability, with sheet membranes offering faster application over large flat areas and liquid-applied systems excelling in versatility and adaptability.

Performance and Durability Comparison

Sheet membrane waterproofing offers consistent thickness and uniform application, resulting in superior resistance to punctures and tears compared to liquid-applied systems. Liquid-applied waterproofing provides excellent adhesion to irregular surfaces and seamless coverage but may require multiple coats to achieve optimal durability. Performance tests show sheet membranes generally outperform liquid membranes in long-term water resistance and UV stability, making them ideal for high-stress environments.

Cost Analysis: Sheet Membrane vs Liquid-Applied

Sheet membrane waterproofing typically involves higher initial material and labor costs due to its pre-fabricated thickness and complex installation process. Liquid-applied waterproofing offers a more cost-effective solution with lower labor expenses and the ability to conform seamlessly to complex surfaces, reducing potential leak points. Your choice should consider long-term maintenance costs, as sheet membranes may require less frequent repairs compared to liquid-applied systems.

Best Use Cases for Each Waterproofing Method

Sheet membrane waterproofing is best suited for large, flat surfaces such as basement walls, foundations, and tunnels where rapid installation and consistent thickness are critical. Liquid-applied waterproofing excels on complex, irregular shapes and details, including balconies, roofs, and parapets, offering seamless coverage and enhanced flexibility. Each method's selection depends on substrate complexity, site accessibility, and desired durability under varying environmental conditions.

Common Problems and How to Avoid Them

Sheet membrane waterproofing often faces issues like improper adhesion, punctures, and seams failure, which can be avoided by meticulous surface preparation and precise installation techniques. Liquid-applied waterproofing commonly suffers from uneven application, cracking, and insufficient curing, preventable through thorough mixing, careful layering, and adherence to manufacturer's drying times. Both methods benefit from quality control inspections and using compatible primers and substrates to enhance durability and performance.

Choosing the Right Waterproofing System for Your Project

Selecting the right waterproofing system depends on project requirements such as surface complexity, durability, and application environment. Sheet membranes offer consistent thickness and controlled quality, ideal for large, flat surfaces requiring long-term protection. Liquid-applied waterproofing provides seamless coverage for intricate shapes and details, enhancing adhesion and flexibility on complex substrates.

Sheet membrane vs liquid-applied waterproofing Infographic

libmatt.com

libmatt.com