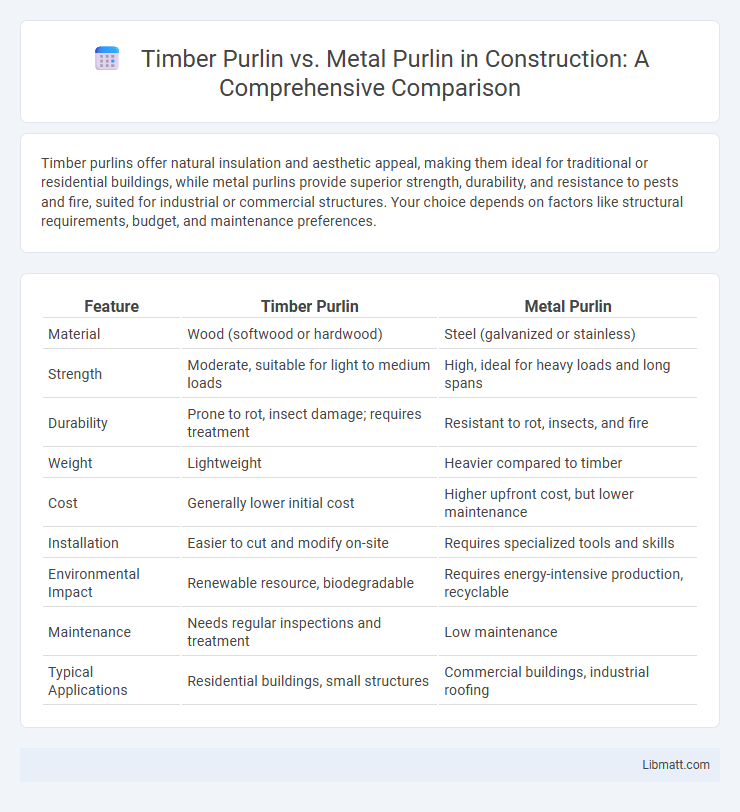

Timber purlins offer natural insulation and aesthetic appeal, making them ideal for traditional or residential buildings, while metal purlins provide superior strength, durability, and resistance to pests and fire, suited for industrial or commercial structures. Your choice depends on factors like structural requirements, budget, and maintenance preferences.

Table of Comparison

| Feature | Timber Purlin | Metal Purlin |

|---|---|---|

| Material | Wood (softwood or hardwood) | Steel (galvanized or stainless) |

| Strength | Moderate, suitable for light to medium loads | High, ideal for heavy loads and long spans |

| Durability | Prone to rot, insect damage; requires treatment | Resistant to rot, insects, and fire |

| Weight | Lightweight | Heavier compared to timber |

| Cost | Generally lower initial cost | Higher upfront cost, but lower maintenance |

| Installation | Easier to cut and modify on-site | Requires specialized tools and skills |

| Environmental Impact | Renewable resource, biodegradable | Requires energy-intensive production, recyclable |

| Maintenance | Needs regular inspections and treatment | Low maintenance |

| Typical Applications | Residential buildings, small structures | Commercial buildings, industrial roofing |

Timber Purlin vs Metal Purlin: Key Differences

Timber purlins offer natural insulation, lightweight properties, and ease of onsite modification, making them ideal for traditional or residential structures. Metal purlins provide superior strength, durability, and resistance to pests and fire, often favored in commercial or industrial buildings. Understanding these key differences helps you select the appropriate material based on your project's structural requirements, budget, and long-term maintenance needs.

Strength and Durability Comparison

Timber purlins offer natural strength and excellent load-bearing capacity, ideal for traditional construction with good resistance to bending under normal conditions. Metal purlins, typically made from galvanized steel, provide superior durability, higher tensile strength, and resistance to pests, rot, and fire, ensuring longer service life in harsher environments. Choosing between timber and metal purlins depends on your project's structural demands and exposure conditions, with metal purlins excelling in strength and longevity for modern industrial applications.

Cost Analysis: Timber vs Metal Purlins

Timber purlins generally offer lower upfront costs due to the abundance and renewability of wood materials, making them a budget-friendly option for smaller or traditional structures. Metal purlins, while initially more expensive, provide long-term savings through superior durability, low maintenance, and resistance to pests and weather damage. Evaluating project scale and lifespan requirements is crucial for a cost-effective decision between timber and metal purlins.

Installation Process and Ease

Timber purlins offer straightforward installation due to their lighter weight and ease of cutting and handling on-site, making them suitable for smaller or residential projects. Metal purlins, although heavier, come pre-fabricated with precision, allowing for faster assembly and consistent alignment in large-scale commercial or industrial applications. The choice between timber and metal purlins depends on project scale, structural requirements, and installer expertise, directly impacting installation speed and complexity.

Maintenance Requirements

Timber purlins require regular inspections for rot, insect damage, and moisture-related issues, with periodic treatments such as sealing or painting to extend their lifespan. Metal purlins demand less frequent maintenance but must be checked for corrosion, especially in coastal or humid environments, with rust-proof coatings applied as needed. Both materials benefit from timely repairs to prevent structural degradation and ensure roof stability.

Environmental Impact and Sustainability

Timber purlins offer a lower environmental impact due to their renewable nature and carbon sequestration properties, making them a sustainable choice when sourced from responsibly managed forests. Metal purlins, often made from steel or aluminum, require significant energy for production and have higher embodied carbon but excel in durability and recyclability at the end of their lifecycle. Choosing timber purlins reduces carbon footprint during manufacturing, while metal purlins provide long-term sustainability through strength and full recyclability, influencing eco-friendly construction decisions.

Applications and Suitability in Construction

Timber purlins offer natural insulation and are ideal for residential and low-rise buildings, providing flexibility in design and ease of installation. Metal purlins, made from steel or aluminum, deliver superior strength, durability, and resistance to pests and fire, making them suitable for industrial, commercial, and high-load structures. Your choice depends on factors such as structural requirements, environmental exposure, and maintenance preferences.

Lifespan and Performance Over Time

Timber purlins typically offer a lifespan of 20 to 30 years, subject to proper treatment and maintenance, while metal purlins can last 50 years or more due to their resistance to rot, pests, and fire. Over time, metal purlins maintain structural integrity with minimal deformation, whereas timber may warp or weaken under prolonged exposure to moisture and environmental factors. For your construction project, choosing metal purlins ensures longer-lasting performance with lower maintenance needs.

Fire Resistance: Timber vs Metal

Timber purlins are less fire-resistant compared to metal purlins due to the combustible nature of wood, which can char and weaken under high temperatures. Metal purlins, typically made from steel or aluminum, provide superior fire resistance as they do not burn and can maintain structural integrity longer during a fire. For your building project, choosing metal purlins enhances fire safety and reduces the risk of structural failure in fire-prone environments.

Which Purlin Is Right for Your Project?

Timber purlins offer natural insulation and aesthetic appeal, making them ideal for residential projects and buildings with traditional designs, while metal purlins provide superior strength, durability, and resistance to pests and fire, suitable for industrial and commercial applications. The choice depends on factors such as load requirements, environmental conditions, budget constraints, and desired lifespan, with metal purlins generally favored for high-load, long-term use and timber purlins preferred for cost-effective, eco-friendly solutions. Evaluating structural demands and maintenance needs will help determine the optimal purlin material for your specific construction project.

Timber purlin vs metal purlin Infographic

libmatt.com

libmatt.com