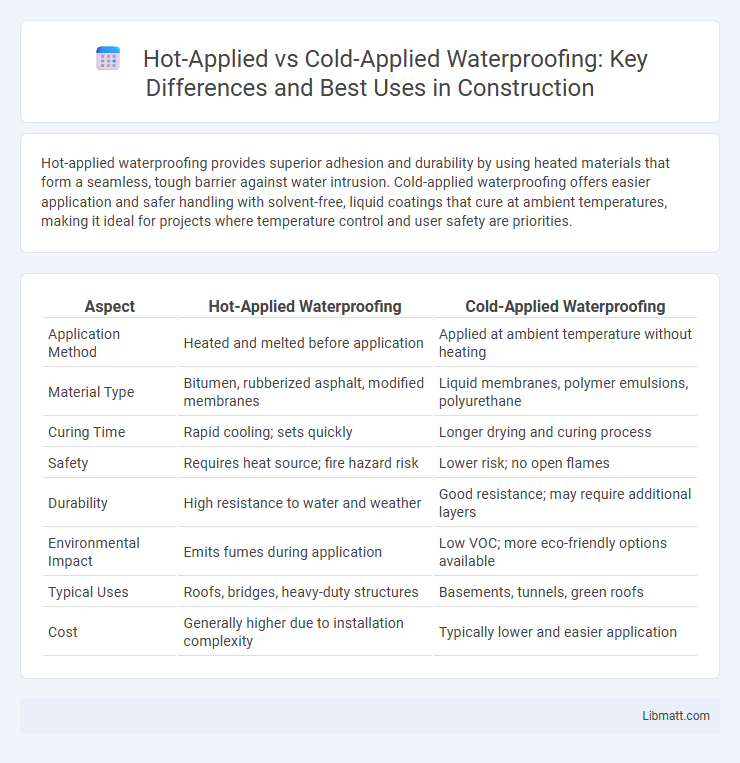

Hot-applied waterproofing provides superior adhesion and durability by using heated materials that form a seamless, tough barrier against water intrusion. Cold-applied waterproofing offers easier application and safer handling with solvent-free, liquid coatings that cure at ambient temperatures, making it ideal for projects where temperature control and user safety are priorities.

Table of Comparison

| Aspect | Hot-Applied Waterproofing | Cold-Applied Waterproofing |

|---|---|---|

| Application Method | Heated and melted before application | Applied at ambient temperature without heating |

| Material Type | Bitumen, rubberized asphalt, modified membranes | Liquid membranes, polymer emulsions, polyurethane |

| Curing Time | Rapid cooling; sets quickly | Longer drying and curing process |

| Safety | Requires heat source; fire hazard risk | Lower risk; no open flames |

| Durability | High resistance to water and weather | Good resistance; may require additional layers |

| Environmental Impact | Emits fumes during application | Low VOC; more eco-friendly options available |

| Typical Uses | Roofs, bridges, heavy-duty structures | Basements, tunnels, green roofs |

| Cost | Generally higher due to installation complexity | Typically lower and easier application |

Introduction to Waterproofing Methods

Hot-applied waterproofing involves melting materials like bitumen to create a seamless, durable barrier that resists moisture penetration effectively. Cold-applied waterproofing uses liquid coatings or membranes that cure at ambient temperatures, offering easier application and enhanced safety without the need for heating equipment. Your choice depends on project requirements, substrate type, and environmental conditions, as both methods provide reliable moisture protection in different scenarios.

Understanding Hot-Applied Waterproofing

Hot-applied waterproofing involves the use of molten bitumen or rubberized asphalt applied at high temperatures, creating a seamless, durable barrier ideal for roofs and foundations. This method provides superior adhesion and elasticity, effectively resisting water infiltration and thermal movement. Your choice of hot-applied waterproofing ensures long-lasting protection in demanding environments with high exposure to moisture and temperature fluctuations.

Overview of Cold-Applied Waterproofing

Cold-applied waterproofing uses liquid membranes that cure at ambient temperatures, offering ease of application without the need for heating equipment. This method provides excellent adhesion and flexibility, making it ideal for complex surfaces and environments where heat application poses safety risks. Your project benefits from reduced labor costs and faster installation compared to hot-applied alternatives, while maintaining high durability and water resistance.

Key Differences Between Hot and Cold Applications

Hot-applied waterproofing involves melting bitumen at high temperatures to create a seamless, durable membrane, while cold-applied methods use liquid or paste products that cure at ambient temperatures, enhancing safety and ease of application. Hot applications provide superior adhesion and resistance to extreme weather, making them ideal for heavy-duty roofs and industrial structures. Cold-applied systems offer faster installation with lower energy consumption and reduced fire hazards, suitable for delicate substrates and environmentally sensitive projects.

Application Processes: Step-by-Step Comparison

Hot-applied waterproofing involves heating bitumen materials to high temperatures until molten, then applying them in layers on the surface, requiring specialized equipment and safety precautions due to the heat. Cold-applied waterproofing uses liquid or paste membranes that cure at ambient temperatures, allowing for simpler application with brushes or rollers and reduced risk of damage from heat exposure. Your choice depends on project scale and site conditions, as hot-applied methods provide thicker, highly durable coatings, while cold-applied options offer easier handling and safer application in confined spaces.

Performance and Durability of Each Method

Hot-applied waterproofing delivers superior adhesion and forms a seamless, flexible membrane that withstands extreme temperatures and heavy foot traffic, ensuring long-lasting durability. Cold-applied waterproofing offers easier application with lower VOC emissions, but it may have reduced elasticity and shorter lifespan under harsh weather conditions. Choosing the right method depends on your project's exposure requirements and desired performance longevity.

Safety Considerations and Environmental Impact

Hot-applied waterproofing involves heating materials to high temperatures, posing burn risks and requiring specialized safety gear, while cold-applied waterproofing reduces these hazards by using ready-to-use products applied at ambient temperatures. Environmental impact favors cold-applied systems, as they typically emit fewer volatile organic compounds (VOCs) and consume less energy during application. Your choice between hot- and cold-applied waterproofing should consider both workplace safety protocols and sustainability goals to minimize health risks and environmental footprint.

Cost Analysis: Hot vs. Cold Waterproofing

Hot-applied waterproofing typically involves higher initial costs due to the necessary heating equipment and safety measures, while cold-applied waterproofing generally offers more cost-effective application with fewer labor requirements. Over time, hot-applied systems may provide better durability and lower maintenance expenses, potentially offsetting their upfront investment. Budget considerations should factor in material costs, labor complexity, installation time, and long-term performance to determine the most economical choice for specific project needs.

Ideal Use Cases for Hot- and Cold-Applied Systems

Hot-applied waterproofing is ideal for large-scale commercial projects, such as flat roofs and bridge decks, where durability and long-term protection against harsh weather are essential. Cold-applied waterproofing suits smaller or residential applications, including basements and balconies, due to its ease of use, quick curing time, and safety benefits without the need for heat. Your choice between hot- and cold-applied systems should consider factors like project size, surface type, and environmental conditions for optimal waterproofing performance.

Choosing the Right Waterproofing Solution

Hot-applied waterproofing offers strong adhesion and durability for high-traffic or industrial surfaces due to its molten application method, making it ideal for roofing and below-grade structures. Cold-applied waterproofing provides ease of use, safety, and environmental benefits through solvent-free or water-based formulas suitable for complex geometries and residential projects. Selecting the right waterproofing solution requires evaluating factors like substrate type, environmental conditions, application speed, and long-term performance needs.

Hot-applied waterproofing vs Cold-applied waterproofing Infographic

libmatt.com

libmatt.com