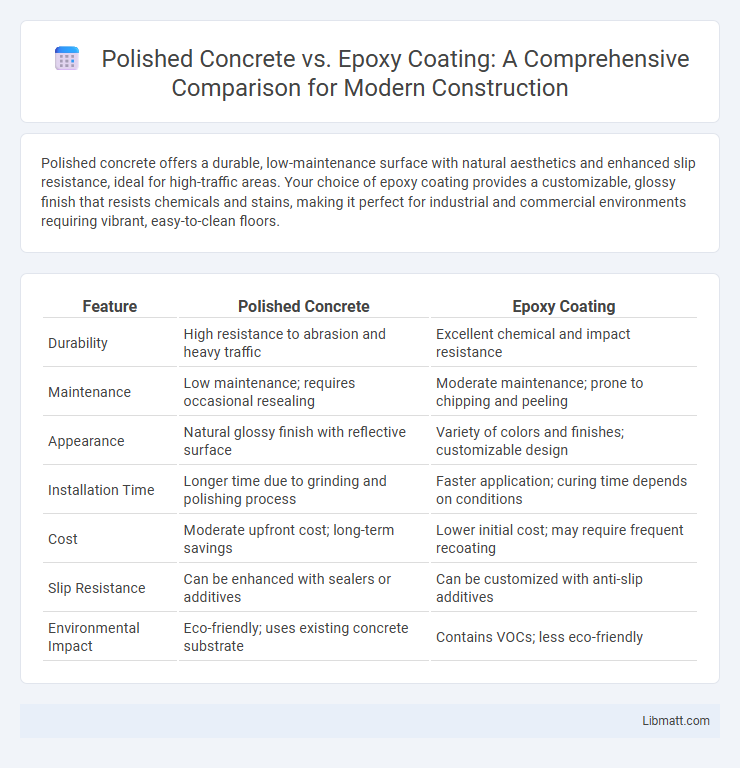

Polished concrete offers a durable, low-maintenance surface with natural aesthetics and enhanced slip resistance, ideal for high-traffic areas. Your choice of epoxy coating provides a customizable, glossy finish that resists chemicals and stains, making it perfect for industrial and commercial environments requiring vibrant, easy-to-clean floors.

Table of Comparison

| Feature | Polished Concrete | Epoxy Coating |

|---|---|---|

| Durability | High resistance to abrasion and heavy traffic | Excellent chemical and impact resistance |

| Maintenance | Low maintenance; requires occasional resealing | Moderate maintenance; prone to chipping and peeling |

| Appearance | Natural glossy finish with reflective surface | Variety of colors and finishes; customizable design |

| Installation Time | Longer time due to grinding and polishing process | Faster application; curing time depends on conditions |

| Cost | Moderate upfront cost; long-term savings | Lower initial cost; may require frequent recoating |

| Slip Resistance | Can be enhanced with sealers or additives | Can be customized with anti-slip additives |

| Environmental Impact | Eco-friendly; uses existing concrete substrate | Contains VOCs; less eco-friendly |

Introduction to Polished Concrete and Epoxy Coating

Polished concrete is a durable, low-maintenance flooring option achieved by mechanically grinding concrete surfaces to a smooth, glossy finish. Epoxy coating involves applying a resin-based layer that provides a high-gloss, protective surface resistant to chemicals and abrasion. Both options enhance your property's aesthetic and functionality, with polished concrete offering natural texture and epoxy coating delivering customizable colors and patterns.

Composition and Application Process

Polished concrete is created by mechanically grinding and polishing the concrete surface with progressively finer abrasive pads, resulting in a smooth and shiny finish that reveals the aggregate beneath. Epoxy coating consists of a two-part resin and hardener mixture that is applied as a liquid and cures into a durable, seamless surface, often requiring proper surface preparation like cleaning and etching. The polished concrete process enhances the existing slab's strength and aesthetics through physical abrasion, whereas epoxy coating provides a protective, customizable layer that bonds chemically to the substrate.

Aesthetic Versatility and Design Options

Polished concrete offers a natural, sleek finish with customizable sheen levels and can incorporate aggregates, stains, and dyes for varied visual effects, making it ideal for minimalist and industrial aesthetics. Epoxy coating provides a broader palette of colors, patterns, and textures, including metallic and high-gloss finishes, enabling intricate designs and vibrant visuals suitable for commercial and decorative spaces. Both options deliver durable surfaces, but epoxy allows for more elaborate customization, while polished concrete emphasizes natural stone beauty and subtle elegance.

Durability and Wear Resistance

Polished concrete offers exceptional durability with high resistance to heavy foot traffic and abrasion, making it ideal for industrial and commercial spaces. Epoxy coating provides a strong, chemical-resistant surface that withstands impact and stains but may be prone to chipping or peeling over time under extreme conditions. Your choice depends on whether you prioritize long-lasting mechanical strength (polished concrete) or a resilient, glossy protective layer (epoxy coating).

Maintenance Requirements and Longevity

Polished concrete requires minimal maintenance, involving regular dust mopping and occasional damp mopping to preserve its shine and durability for up to 20 years or more. Epoxy coatings need more frequent upkeep, including spot cleaning and periodic reapplication every 3 to 7 years to maintain their protective and aesthetic qualities. The longevity of polished concrete surpasses epoxy, making it a cost-effective option for high-traffic areas with lower maintenance demands.

Cost Comparison and Budget Considerations

Polished concrete typically costs between $3 to $12 per square foot, making it a more affordable option compared to epoxy coatings, which range from $4 to $7 per square foot but may require additional surface preparation and maintenance costs. While polished concrete offers durability with minimal upkeep, epoxy coatings provide a glossy finish but may incur higher long-term expenses due to periodic recoating and repair. Understanding these cost factors helps you make informed budget decisions for flooring that balances initial investment with maintenance requirements.

Slip Resistance and Safety Factors

Polished concrete offers moderate slip resistance due to its smooth, glossy finish, making it essential to apply anti-slip treatments in high-traffic or wet areas to enhance safety. Epoxy coatings can be formulated with textured additives such as silicone or aluminum oxide to significantly improve slip resistance, providing a safer surface in industrial and commercial settings. Safety factors favor epoxy coatings when customized for specific environments, while polished concrete requires additional measures to meet stringent slip-resistance standards.

Environmental Impact and Sustainability

Polished concrete offers a sustainable flooring option by utilizing the existing slab, reducing the need for additional materials and minimizing waste. Epoxy coatings, while durable, often contain volatile organic compounds (VOCs) that can contribute to indoor air pollution and environmental harm during production and application. Choosing polished concrete can lower your carbon footprint and promote healthier indoor air quality by avoiding synthetic chemical coatings.

Ideal Use Cases and Industry Applications

Polished concrete excels in high-traffic commercial spaces such as retail stores, warehouses, and airports due to its durability, low maintenance, and natural aesthetic appeal. Epoxy coating is ideal for environments requiring chemical resistance and enhanced safety features, including manufacturing plants, automotive garages, and healthcare facilities. Your choice depends on whether you prioritize long-lasting natural finish or protective, customizable surface solutions tailored to industrial demands.

Choosing the Right Flooring Solution

Polished concrete offers a durable, low-maintenance surface with natural aesthetic appeal, ideal for high-traffic commercial and industrial spaces. Epoxy coating provides a customizable finish with superior chemical resistance and vibrant color options, perfect for garages, warehouses, and areas requiring enhanced protection. Selecting the right flooring solution depends on factors such as durability needs, exposure to chemicals, desired appearance, and budget constraints.

Polished concrete vs Epoxy coating Infographic

libmatt.com

libmatt.com