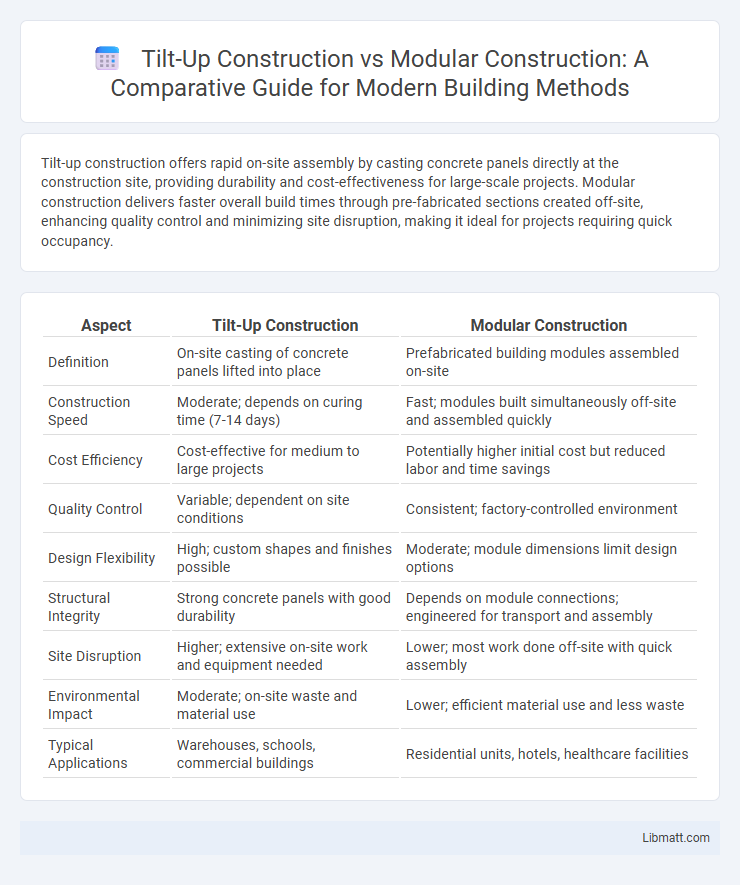

Tilt-up construction offers rapid on-site assembly by casting concrete panels directly at the construction site, providing durability and cost-effectiveness for large-scale projects. Modular construction delivers faster overall build times through pre-fabricated sections created off-site, enhancing quality control and minimizing site disruption, making it ideal for projects requiring quick occupancy.

Table of Comparison

| Aspect | Tilt-Up Construction | Modular Construction |

|---|---|---|

| Definition | On-site casting of concrete panels lifted into place | Prefabricated building modules assembled on-site |

| Construction Speed | Moderate; depends on curing time (7-14 days) | Fast; modules built simultaneously off-site and assembled quickly |

| Cost Efficiency | Cost-effective for medium to large projects | Potentially higher initial cost but reduced labor and time savings |

| Quality Control | Variable; dependent on site conditions | Consistent; factory-controlled environment |

| Design Flexibility | High; custom shapes and finishes possible | Moderate; module dimensions limit design options |

| Structural Integrity | Strong concrete panels with good durability | Depends on module connections; engineered for transport and assembly |

| Site Disruption | Higher; extensive on-site work and equipment needed | Lower; most work done off-site with quick assembly |

| Environmental Impact | Moderate; on-site waste and material use | Lower; efficient material use and less waste |

| Typical Applications | Warehouses, schools, commercial buildings | Residential units, hotels, healthcare facilities |

Introduction to Tilt-Up and Modular Construction

Tilt-up construction involves casting concrete panels onsite, allowing for rapid assembly and durable structural elements, commonly used in commercial and industrial buildings. Modular construction features pre-fabricated building components assembled offsite, offering high precision, reduced construction time, and minimized waste. Your choice between tilt-up and modular methods depends on project scope, timeline, and budget considerations, with each approach delivering distinct advantages in efficiency and flexibility.

Key Differences Between Tilt-Up and Modular Construction

Tilt-up construction involves casting concrete panels on-site, enabling rapid formation of durable building exteriors, while modular construction consists of prefabricating building sections in a factory for faster assembly on-site. Tilt-up methods excel in large-scale commercial projects requiring custom concrete finishes, whereas modular construction offers superior speed and cost efficiency for repetitive, standardized units. The choice between tilt-up and modular construction impacts project timelines, cost structures, and design flexibility based on the specific building requirements and site conditions.

Speed of Construction: Which Method is Faster?

Tilt-up construction typically offers faster onsite assembly since concrete panels are cast on-site and lifted into place, minimizing delays related to transportation and fit. Modular construction accelerates overall project timelines by fabricating building components off-site in controlled environments simultaneously with site preparation, reducing weather-related interruptions. Projects with tight schedules may benefit from modular methods due to parallel processing, while tilt-up suits large-scale structures where rapid panel erection is crucial.

Cost Comparison: Tilt-Up vs Modular

Tilt-up construction typically offers lower initial material and labor costs compared to modular construction due to on-site fabrication and bulk concrete use. Modular construction can reduce overall expenses by minimizing construction time and labor through prefabricated components, leading to faster project completion and potential savings in financing and site management. Your choice depends on balancing upfront cost savings with the benefits of accelerated timelines and controlled factory conditions.

Design Flexibility and Customization Options

Tilt-up construction allows for significant design flexibility with large, monolithic concrete panels that can be custom-shaped and textured directly on-site, enabling unique architectural features and expansive open layouts. Modular construction offers high customization through prefabricated modules built in controlled factory settings, allowing for precise finishes and easy integration of various design elements that can be assembled rapidly on-site. Both methods support customization, but tilt-up excels in large-scale unique structural designs while modular construction provides consistent quality and faster turnaround for repetitive or scalable designs.

Structural Strength and Durability

Tilt-up construction offers exceptional structural strength by casting concrete panels on-site, creating robust, monolithic walls known for their durability and resistance to fire, weather, and pests. Modular construction uses factory-produced sections that are engineered for strength with steel frames and reinforced materials, ensuring consistent quality and durability with the advantage of faster assembly. Your choice between the two depends on the priority of on-site customization or expedited build time, while both methods provide long-lasting structural integrity for commercial and residential projects.

Sustainability and Environmental Impact

Tilt-up construction reduces environmental impact by minimizing waste through on-site casting of concrete panels, which often incorporate recycled materials and improve thermal performance, leading to lower energy consumption during a building's lifecycle. Modular construction significantly enhances sustainability by enabling precise factory fabrication, reducing material waste, and lowering carbon emissions associated with transportation and on-site construction activities. Both methods support sustainable building practices, with tilt-up offering durable, energy-efficient structures and modular allowing rapid, efficient assembly that reduces site disturbance and construction timelines.

Ideal Applications for Tilt-Up Construction

Tilt-up construction is ideal for low to mid-rise commercial buildings such as warehouses, retail stores, and office complexes where large, repetitive wall panels can be efficiently cast on-site and rapidly erected. This method excels in projects requiring durable, fire-resistant exterior walls with excellent thermal mass, making it suitable for climates with extreme temperature variations. Tilt-up construction is also preferred for large footprint buildings that benefit from cost-effective, shorter construction timelines without the need for intricate design complexity.

Ideal Applications for Modular Construction

Modular construction is ideal for projects requiring accelerated timelines, consistent quality control, and repetitive design elements, such as hotels, multi-family housing, and educational facilities. Its factory-based manufacturing process enables efficient mass production and reduced on-site labor, making it suitable for urban areas with limited space. The flexibility in design and ease of expansion also make modular construction advantageous for healthcare and commercial buildings demanding scalability.

Choosing the Right Method for Your Project

Tilt-up construction offers rapid on-site assembly and cost-effective material use, making it ideal for large commercial buildings with customizable design features. Modular construction provides enhanced quality control, reduced construction time, and environmental benefits by assembling pre-fabricated units off-site, suitable for projects requiring tight schedules and consistent finishes. Evaluating project size, timeline, budget, and design complexity will determine whether the versatility of tilt-up or the precision of modular construction best meets your construction goals.

Tilt-up construction vs modular construction Infographic

libmatt.com

libmatt.com