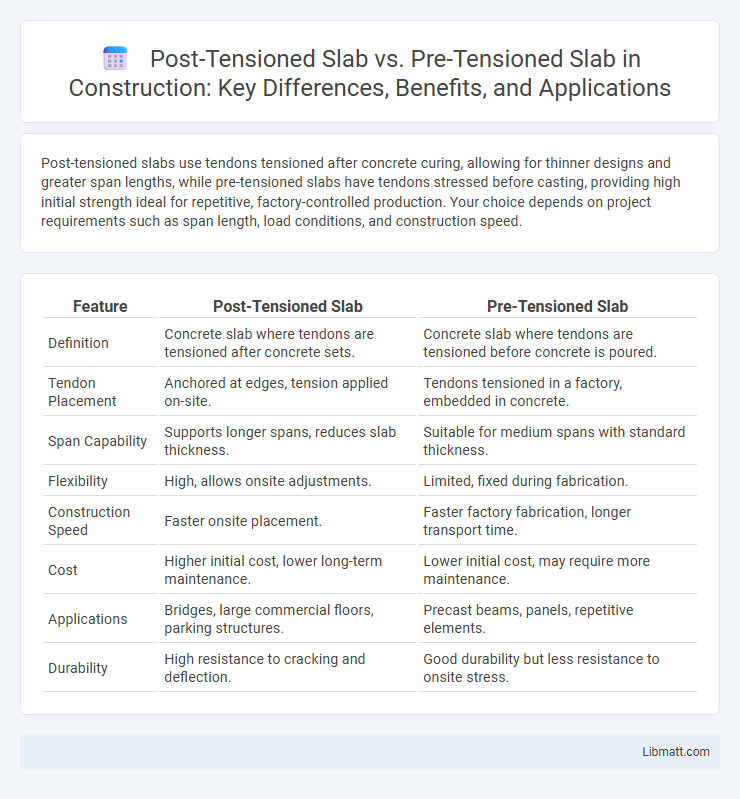

Post-tensioned slabs use tendons tensioned after concrete curing, allowing for thinner designs and greater span lengths, while pre-tensioned slabs have tendons stressed before casting, providing high initial strength ideal for repetitive, factory-controlled production. Your choice depends on project requirements such as span length, load conditions, and construction speed.

Table of Comparison

| Feature | Post-Tensioned Slab | Pre-Tensioned Slab |

|---|---|---|

| Definition | Concrete slab where tendons are tensioned after concrete sets. | Concrete slab where tendons are tensioned before concrete is poured. |

| Tendon Placement | Anchored at edges, tension applied on-site. | Tendons tensioned in a factory, embedded in concrete. |

| Span Capability | Supports longer spans, reduces slab thickness. | Suitable for medium spans with standard thickness. |

| Flexibility | High, allows onsite adjustments. | Limited, fixed during fabrication. |

| Construction Speed | Faster onsite placement. | Faster factory fabrication, longer transport time. |

| Cost | Higher initial cost, lower long-term maintenance. | Lower initial cost, may require more maintenance. |

| Applications | Bridges, large commercial floors, parking structures. | Precast beams, panels, repetitive elements. |

| Durability | High resistance to cracking and deflection. | Good durability but less resistance to onsite stress. |

Introduction to Prestressed Concrete: Post-tensioned vs Pre-tensioned Slabs

Post-tensioned slabs use steel tendons tensioned after concrete curing, allowing for longer spans and reduced cracking compared to pre-tensioned slabs, which have tendons tensioned before concrete placement. This method optimizes load distribution and structural efficiency in construction projects. Understanding these differences helps you select the best prestressed concrete technique for your specific design and performance requirements.

Basics of Post-tensioned Slab Construction

Post-tensioned slab construction involves placing high-strength steel tendons within the concrete formwork, which are tensioned after the concrete has gained sufficient strength, enhancing the slab's load-carrying capacity and reducing cracking. Tendons are threaded through ducts embedded in the slab and anchored at the edges, allowing for controlled compression that counteracts tensile forces during service. This technique enables longer spans, thinner slabs, and improved structural efficiency compared to traditional reinforced concrete methods.

Fundamentals of Pre-tensioned Slab Construction

Pre-tensioned slab construction involves tensioning steel tendons before casting concrete, ensuring high tensile strength and improved load distribution once the concrete hardens. This method offers enhanced durability and reduced slab thickness compared to conventional reinforced slabs. Your project benefits from faster construction times and superior crack control due to the pre-stressed reinforcement embedded within the slab.

Key Material and Equipment Differences

Post-tensioned slabs use high-strength steel tendons placed inside ducts within the concrete and tensioned after the concrete cures, requiring hydraulic jacks and anchorage systems. Pre-tensioned slabs employ steel strands tensioned before casting, anchored externally, demanding a casting bed with stressing beds and anchorage frames. The material distinction lies in tendon placement and tensioning timing, impacting equipment such as jacks for post-tensioning versus stressing beds for pre-tensioning.

Structural Performance: Strength and Durability Comparison

Post-tensioned slabs exhibit higher tensile strength and enhanced crack control due to the active tension applied after concrete curing, resulting in improved durability and load-bearing capacity compared to pre-tensioned slabs. Pre-tensioned slabs, while strong and consistent due to tensioning before casting, typically have lower adaptability to variable loads and are more prone to shrinkage-induced cracking. The active stress introduced in post-tensioned slabs effectively counters tensile stresses during service, making them preferable for longer spans and heavy-load applications.

Typical Applications in Modern Construction

Post-tensioned slabs are commonly used in large-span structures such as parking garages, bridges, and high-rise buildings due to their ability to handle heavy loads and reduce slab thickness. Pre-tensioned slabs find typical applications in precast concrete elements like floor planks, beams, and wall panels where mass production and uniform quality are essential. Both techniques enhance structural performance but vary in onsite installation complexity and cost efficiency, influencing their selection in modern construction projects.

Cost Considerations: Installation and Long-term Value

Post-tensioned slabs typically have lower installation costs due to easier on-site tensioning and reduced formwork requirements, making them cost-effective for large or irregular slabs. Pre-tensioned slabs, while often more expensive upfront because they require factory fabrication and transportation, provide consistent quality and durability that contributes to long-term structural value. Your choice should weigh initial budget constraints against potential savings in maintenance and lifespan, with post-tensioned slabs offering flexible design options and pre-tensioned slabs ensuring high-performance standards.

Design Flexibility and Architectural Implications

Post-tensioned slabs offer greater design flexibility by allowing longer spans and thinner slabs, which enable more open architectural spaces and fewer columns. Pre-tensioned slabs are typically standardized and manufactured off-site, resulting in less adaptability to unique design requirements but faster construction times. Your choice between these systems directly influences structural aesthetics and functional possibilities in building layouts.

Common Challenges and Solutions in Implementation

Post-tensioned slabs often face challenges such as tendon corrosion and complex site installation requiring skilled labor, mitigated by using high-quality corrosion-resistant materials and comprehensive training programs. Pre-tensioned slabs encounter difficulties with transportation and handling due to their pre-fabricated nature, addressed by optimizing slab dimensions for easier logistics and employing specialized rigging equipment. Both systems demand rigorous quality control and accurate tensioning measurements to ensure structural integrity and durability during construction and service life.

Choosing the Right Slab System for Your Project

Post-tensioned slabs offer greater flexibility for longer spans and reduced slab thickness, making them ideal for projects requiring minimal support columns and enhanced load capacity. Pre-tensioned slabs provide high early strength and consistent quality, often preferred in controlled factory environments for repetitive structural elements like beams and floor panels. You should consider the specific project requirements, such as span length, construction timeline, and site conditions, to choose the most efficient and cost-effective slab system.

Post-tensioned slab vs pre-tensioned slab Infographic

libmatt.com

libmatt.com