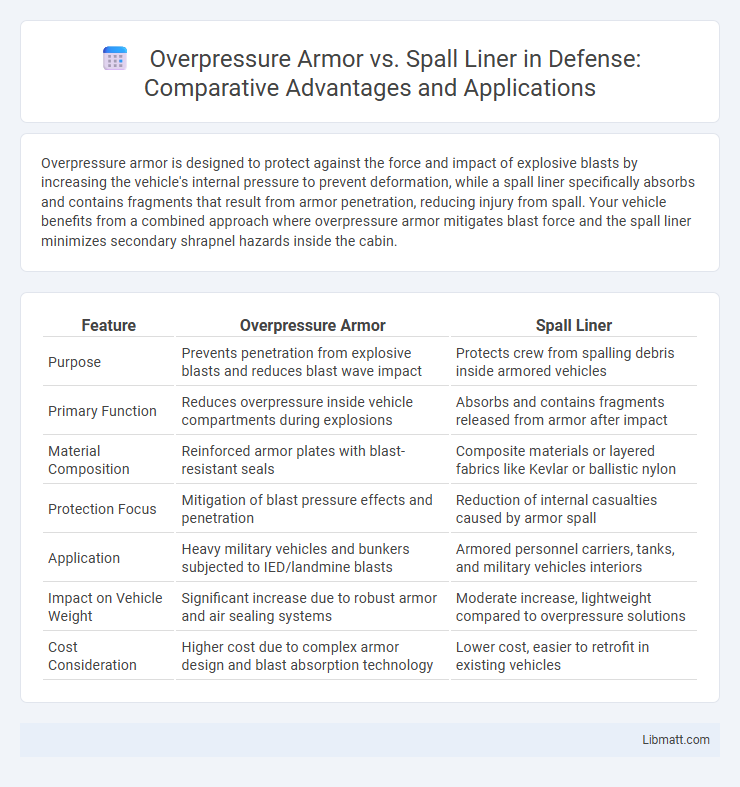

Overpressure armor is designed to protect against the force and impact of explosive blasts by increasing the vehicle's internal pressure to prevent deformation, while a spall liner specifically absorbs and contains fragments that result from armor penetration, reducing injury from spall. Your vehicle benefits from a combined approach where overpressure armor mitigates blast force and the spall liner minimizes secondary shrapnel hazards inside the cabin.

Table of Comparison

| Feature | Overpressure Armor | Spall Liner |

|---|---|---|

| Purpose | Prevents penetration from explosive blasts and reduces blast wave impact | Protects crew from spalling debris inside armored vehicles |

| Primary Function | Reduces overpressure inside vehicle compartments during explosions | Absorbs and contains fragments released from armor after impact |

| Material Composition | Reinforced armor plates with blast-resistant seals | Composite materials or layered fabrics like Kevlar or ballistic nylon |

| Protection Focus | Mitigation of blast pressure effects and penetration | Reduction of internal casualties caused by armor spall |

| Application | Heavy military vehicles and bunkers subjected to IED/landmine blasts | Armored personnel carriers, tanks, and military vehicles interiors |

| Impact on Vehicle Weight | Significant increase due to robust armor and air sealing systems | Moderate increase, lightweight compared to overpressure solutions |

| Cost Consideration | Higher cost due to complex armor design and blast absorption technology | Lower cost, easier to retrofit in existing vehicles |

Introduction to Overpressure Armor

Overpressure armor protects against blast and shock waves by creating a sealed environment that maintains higher internal pressure to prevent hazardous contaminants from entering. This technology is crucial for military vehicles and protective structures, providing enhanced safety in explosive or chemical attack scenarios. Your safety relies on the effective integration of overpressure armor to withstand extreme external forces while maintaining breathable air inside.

Understanding Spall Liners

Spall liners function as internal protective layers within armored vehicles, designed to absorb and contain fragments generated when armor is struck by projectiles or explosive forces. Unlike overpressure armor that primarily counters blast pressure waves, spall liners reduce crew injuries by minimizing the dispersion of lethal spall debris inside the vehicle's compartment. Materials such as aramid fibers and ultra-high-molecular-weight polyethylene are commonly used in spall liners to enhance energy absorption and prevent penetration of secondary fragments.

Key Functions of Overpressure Armor

Overpressure armor primarily functions to protect military vehicles by creating a sealed environment that prevents toxic gases, chemical agents, and contaminants from entering during chemical, biological, radiological, and nuclear (CBRN) threats. It maintains positive internal pressure to safeguard occupants while allowing safe breathing and operational effectiveness in hazardous environments. This system differs from spall liners, which focus on mitigating the impact of shrapnel and fragments rather than filtering airborne threats.

Protective Capabilities of Spall Liners

Spall liners provide a critical layer of protection by absorbing and deflecting fragments from armor penetration, significantly reducing the risk of injury from spall and secondary projectiles inside the vehicle or enclosed space. Unlike overpressure armor, which is designed to counter blast pressures and explosive forces, spall liners focus on preventing shrapnel and debris from causing harm to occupants. Your safety inside armored vehicles improves dramatically with high-quality spall liners, which enhance survivability without the weight penalties associated with overpressure armor systems.

Comparison of Blast Mitigation Performance

Overpressure armor and spall liners serve distinct roles in blast mitigation, with overpressure armor primarily designed to withstand and reduce the impact of shock waves caused by explosions, effectively safeguarding structures and personnel from high-pressure blasts. Spall liners function to prevent secondary fragmentation by catching and containing debris generated inside armored vehicles or shelters during an explosion, thereby reducing injury risks from shrapnel. Your choice depends on whether the primary threat is the blast overpressure itself or the resulting spall fragments, as both systems complement each other but address different mechanisms of blast injuries.

Weight and Integration Considerations

Overpressure armor typically adds significant weight to vehicles due to its heavy-duty construction designed to withstand high-pressure blasts, potentially impacting fuel efficiency and mobility. In contrast, spall liners are lighter, incorporating advanced composite materials that integrate seamlessly within armored compartments without substantially increasing vehicle mass. Your choice between overpressure armor and spall liners should consider the balance of protection needs against weight constraints and integration compatibility with existing vehicle systems.

Cost Differences and Budget Implications

Overpressure armor typically involves higher material and manufacturing costs than spall liners due to its complex design aimed at blast containment. Spall liners offer a more budget-friendly solution by providing effective protection against fragments at a lower price point and simpler installation process. Understanding these cost differences helps you allocate resources efficiently when planning vehicle or personal armor upgrades.

Maintenance and Durability Factors

Overpressure armor requires regular inspection and sealing to maintain its airtight integrity, as any breach can compromise its protective function and durability. Spall liners, made from advanced composite materials, generally offer greater resistance to wear and impact, reducing the frequency of maintenance while ensuring long-lasting protection against fragmentation. Your choice should consider the operational environment and maintenance capabilities to maximize the lifespan and effectiveness of the protective system.

Suitability for Various Vehicle Types

Overpressure armor is highly suitable for larger military vehicles such as armored personnel carriers and infantry fighting vehicles, where maintaining internal air pressure protects occupants from chemical, biological, and radiological threats. Spall liners are more versatile and can be effectively installed in a wider range of vehicle types, including lighter vehicles and tanks, providing protection against fragments from armor penetration. Your choice between the two depends on the vehicle size, mission requirements, and level of protection needed against specific threats.

Future Trends in Vehicle Armor Technology

Future trends in vehicle armor technology emphasize the integration of overpressure armor systems with advanced spall liners to enhance crew survivability against explosive threats. Overpressure armor actively manages blast waves and toxic gases inside the vehicle, while innovative spall liners now utilize multi-layered composites to effectively contain and absorb high-velocity fragments. Your vehicle's protection will soon benefit from smart, adaptive armor systems combining overpressure control and next-generation spall liners for superior defense in increasingly complex battlefield environments.

overpressure armor vs spall liner Infographic

libmatt.com

libmatt.com