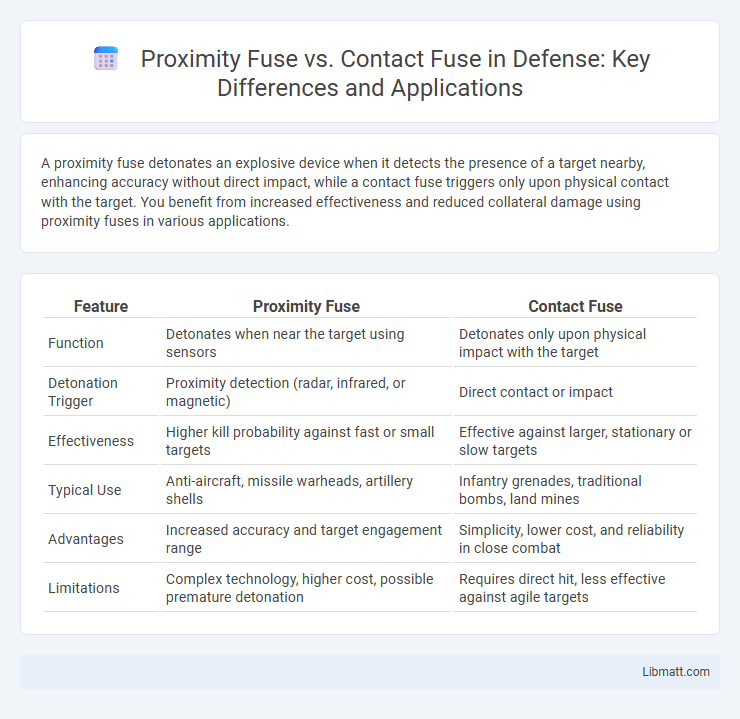

A proximity fuse detonates an explosive device when it detects the presence of a target nearby, enhancing accuracy without direct impact, while a contact fuse triggers only upon physical contact with the target. You benefit from increased effectiveness and reduced collateral damage using proximity fuses in various applications.

Table of Comparison

| Feature | Proximity Fuse | Contact Fuse |

|---|---|---|

| Function | Detonates when near the target using sensors | Detonates only upon physical impact with the target |

| Detonation Trigger | Proximity detection (radar, infrared, or magnetic) | Direct contact or impact |

| Effectiveness | Higher kill probability against fast or small targets | Effective against larger, stationary or slow targets |

| Typical Use | Anti-aircraft, missile warheads, artillery shells | Infantry grenades, traditional bombs, land mines |

| Advantages | Increased accuracy and target engagement range | Simplicity, lower cost, and reliability in close combat |

| Limitations | Complex technology, higher cost, possible premature detonation | Requires direct hit, less effective against agile targets |

Introduction to Proximity Fuses and Contact Fuses

Proximity fuses use electronic sensors to detect the presence of a target nearby and detonate the explosive at the optimal distance, increasing accuracy and effectiveness against fast-moving or airborne objects. Contact fuses require physical impact with the target to trigger detonation, making them best suited for direct hits but less efficient against rapidly moving or evasive targets. Your choice between proximity and contact fuses depends on the mission requirements, target type, and desired detonation timing for maximum impact.

Key Differences Between Proximity and Contact Fuses

Proximity fuses detonate explosives when they sense a target within a specific range using radio or radar signals, whereas contact fuses require direct physical impact to trigger detonation. Proximity fuses enhance effectiveness by detonating near the target, increasing fragmentation and damage radius without needing a direct hit. Contact fuses rely on mechanical or electronic impact sensors, making them simpler but less effective against fast-moving or evasive targets.

How Proximity Fuses Work

Proximity fuses detect the presence of a target using radio waves or electromagnetic signals, triggering detonation when the projectile is near the target. Unlike contact fuses, which require direct impact to activate, proximity fuses enable more precise and timely explosions, increasing effectiveness against moving or airborne objects. Your defense systems benefit from this advanced technology by improving accuracy and maximizing damage efficiency without relying on physical contact.

Operation of Contact Fuses Explained

Contact fuses operate by detonating upon direct physical impact with a target, triggering the explosive charge instantly to maximize damage at the point of contact. These fuses rely on mechanical or electrical triggers that close a circuit or release a firing pin when force is applied, ensuring immediate activation. Compared to proximity fuses, contact fuses do not detect distance or velocity but depend entirely on physical collision to initiate detonation.

Applications of Proximity Fuses in Modern Warfare

Proximity fuses revolutionize modern warfare by enabling munitions to detonate near targets without direct impact, drastically increasing effectiveness against aerial threats such as missiles, drones, and aircraft. These fuses utilize radio waves or radar signals to detect optimal detonation distances, enhancing accuracy and reducing collateral damage compared to contact fuses. Key applications include anti-aircraft artillery, guided missile systems, and smart bombs, where precise timing ensures maximum destructive impact on fast-moving or evasive targets.

Role of Contact Fuses in Conventional Munitions

Contact fuses play a crucial role in conventional munitions by detonating explosives upon direct impact with a target, ensuring immediate activation and maximum damage at the point of contact. These fuses are essential for targeting armor, fortifications, and other solid structures where precise timing and contact-triggered explosions are required. Their reliability and simplicity make contact fuses fundamental components in anti-tank shells, artillery rounds, and demolition charges.

Advantages of Proximity Fuses Over Contact Fuses

Proximity fuses significantly enhance detonation precision by activating explosives near the target rather than upon direct impact, increasing effectiveness against fast-moving or small objects like aircraft and missiles. They reduce the likelihood of duds caused by impact failures, improving overall reliability and combat efficiency. These fuses enable safer and more versatile applications in varying environmental conditions, offering superior performance compared to traditional contact fuses.

Limitations and Challenges of Both Fuse Types

Proximity fuses face limitations such as sensitivity to electromagnetic interference and reduced effectiveness against targets with low radar reflectivity, while contact fuses rely on direct physical impact, restricting their use against fast or maneuvering targets. Both fuse types encounter challenges in reliability and environmental susceptibility, with proximity fuses potentially triggering prematurely and contact fuses failing if the impact angle is insufficient. Understanding these constraints is crucial to selecting the appropriate fuse type for your specific operational needs.

Safety and Reliability Considerations

Proximity fuses enhance safety by detonating warheads at a precise distance, reducing the risk of unintended explosions and increasing operational reliability through advanced sensor technology. Contact fuses trigger upon direct impact, which may pose higher risks of premature detonation or failure in complex environments. Your choice between these fuse types depends on mission-specific safety requirements and the desired reliability performance.

Future Developments in Fuse Technology

Future developments in fuse technology emphasize enhancing the precision and reliability of proximity fuses through advanced sensor integration, such as miniaturized radar and lidar systems, improving target detection in complex environments. Contact fuses are evolving with smart materials and microelectromechanical systems (MEMS) to increase sensitivity and reduce accidental detonations, optimizing performance in increasingly cluttered battlefields. Research into AI-driven fuse algorithms aims to adapt detonation timing dynamically, blending proximity and contact fuse advantages for next-generation ordnance effectiveness.

proximity fuse vs contact fuse Infographic

libmatt.com

libmatt.com