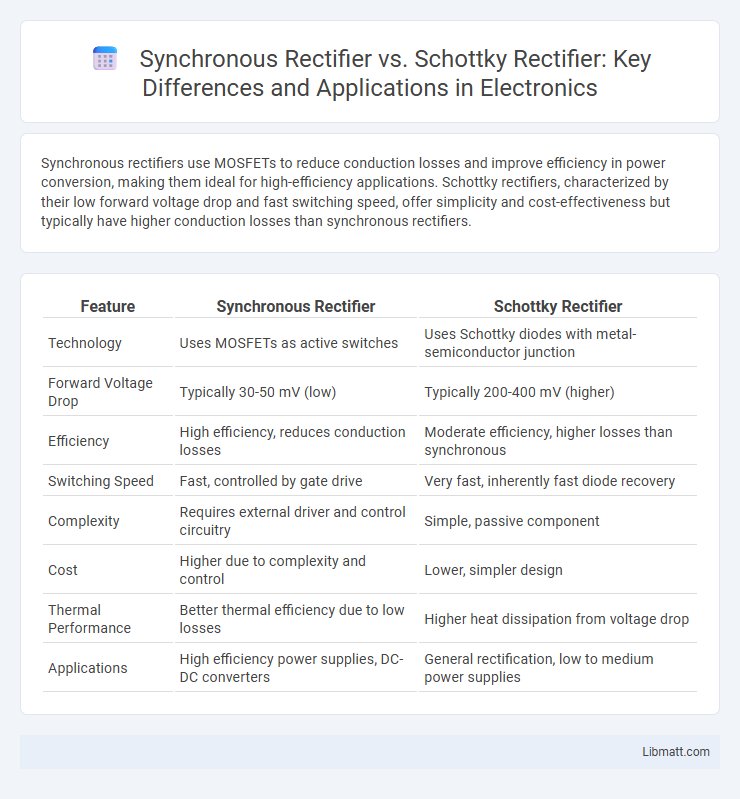

Synchronous rectifiers use MOSFETs to reduce conduction losses and improve efficiency in power conversion, making them ideal for high-efficiency applications. Schottky rectifiers, characterized by their low forward voltage drop and fast switching speed, offer simplicity and cost-effectiveness but typically have higher conduction losses than synchronous rectifiers.

Table of Comparison

| Feature | Synchronous Rectifier | Schottky Rectifier |

|---|---|---|

| Technology | Uses MOSFETs as active switches | Uses Schottky diodes with metal-semiconductor junction |

| Forward Voltage Drop | Typically 30-50 mV (low) | Typically 200-400 mV (higher) |

| Efficiency | High efficiency, reduces conduction losses | Moderate efficiency, higher losses than synchronous |

| Switching Speed | Fast, controlled by gate drive | Very fast, inherently fast diode recovery |

| Complexity | Requires external driver and control circuitry | Simple, passive component |

| Cost | Higher due to complexity and control | Lower, simpler design |

| Thermal Performance | Better thermal efficiency due to low losses | Higher heat dissipation from voltage drop |

| Applications | High efficiency power supplies, DC-DC converters | General rectification, low to medium power supplies |

Introduction to Rectifiers: Synchronous vs Schottky

Synchronous rectifiers utilize MOSFETs to replace diodes, offering lower on-resistance and improved efficiency in power conversion applications. Schottky rectifiers employ metal-semiconductor junctions, providing fast switching speeds and low forward voltage drops, which reduce power losses at high frequencies. Comparing both, synchronous rectifiers excel in efficiency for low-voltage, high-current scenarios, while Schottky rectifiers are favored for simplicity and reliable performance in moderately high-frequency circuits.

Basic Operating Principles

Synchronous rectifiers use MOSFETs to achieve low forward voltage drop by actively switching in sync with the input waveform, significantly improving efficiency in DC-DC converters. Schottky rectifiers rely on a metal-semiconductor junction to provide fast switching and low forward voltage drop without the need for external control signals. The basic principle of synchronous rectification involves controlled conduction to minimize power loss, whereas Schottky rectification depends on inherent diode properties for rapid response and low voltage drop.

Efficiency Comparison

Synchronous rectifiers provide higher efficiency than Schottky rectifiers by using MOSFETs, which offer lower voltage drops and reduced power loss during conduction. Schottky rectifiers typically suffer from higher forward voltage and increased heat dissipation, making them less efficient at higher currents. To optimize your power conversion system's efficiency, choosing synchronous rectification is often the superior option in low-voltage, high-current applications.

Switching Speed and Performance

Synchronous rectifiers offer significantly faster switching speeds compared to Schottky rectifiers due to their use of MOSFETs, which reduces conduction losses and improves overall efficiency. Schottky rectifiers, while providing low forward voltage drop and quick recovery times, generally have slower switching capabilities and higher power dissipation under high-frequency conditions. Your choice between these rectifiers impacts the performance optimization in switching power supplies, especially in high-frequency and high-efficiency applications.

Thermal Management and Heat Dissipation

Synchronous Rectifiers offer superior thermal management compared to Schottky Rectifiers due to their lower conduction losses, which significantly reduces heat generation in power conversion circuits. Effective heat dissipation is enhanced in synchronous rectifiers through optimized MOSFET design and integrated cooling solutions, enabling higher efficiency under heavy load conditions. Your choice between these rectifiers directly impacts system reliability and thermal performance in high-current applications.

Cost Considerations

Synchronous rectifiers generally have higher upfront costs due to the need for MOSFETs and complex driver circuitry, but they offer improved efficiency which can reduce long-term energy expenses in your power conversion systems. Schottky rectifiers are more cost-effective initially, featuring simpler designs and no gate drive requirements, making them suitable for budget-sensitive or low-power applications. Evaluating the total cost of ownership requires balancing initial investment against efficiency gains and thermal management savings.

Applications and Use Cases

Synchronous rectifiers are widely used in high-efficiency power supplies, DC-DC converters, and low-voltage, high-current applications due to their reduced conduction losses compared to Schottky rectifiers. Schottky rectifiers are preferred in high-frequency circuits, low-voltage drop applications, and reverse voltage protection because of their fast switching speed and low forward voltage drop. Both technologies play critical roles in power management systems, with synchronous rectifiers dominating in energy-sensitive designs and Schottky rectifiers excelling in RF and high-speed switching environments.

Design Complexity and Circuit Integration

Synchronous rectifiers feature MOSFETs controlled by gate drivers, increasing design complexity but enabling higher efficiency and better thermal performance compared to Schottky rectifiers, which use simpler diode structures with minimal control requirements. Integration of synchronous rectifiers requires precise timing circuits and often dedicated ICs to optimize switching, while Schottky rectifiers offer plug-and-play operation with fewer layout constraints. These differences make synchronous rectifiers more suitable for advanced power systems demanding efficiency, whereas Schottky rectifiers excel in straightforward, cost-sensitive applications.

Reliability and Lifespan

Synchronous rectifiers typically offer higher reliability and longer lifespan due to their lower conduction losses and reduced heat generation, which minimize thermal stress on components. Schottky rectifiers, while efficient at high switching speeds, often experience greater leakage currents and higher junction temperatures, potentially reducing their operational lifespan. Optimal thermal management and component quality are crucial for maximizing reliability in both rectifier types within power conversion applications.

Choosing the Right Rectifier for Your Project

Choosing the right rectifier for your project depends on factors like efficiency, voltage drop, and thermal performance. Synchronous rectifiers offer lower conduction losses and higher efficiency in low-voltage, high-current applications by using MOSFETs, while Schottky rectifiers provide fast switching and low forward voltage drop, ideal for high-frequency circuits. Your decision should balance cost, efficiency requirements, and thermal management to optimize power conversion and reliability.

Synchronous Rectifier vs Schottky Rectifier Infographic

libmatt.com

libmatt.com