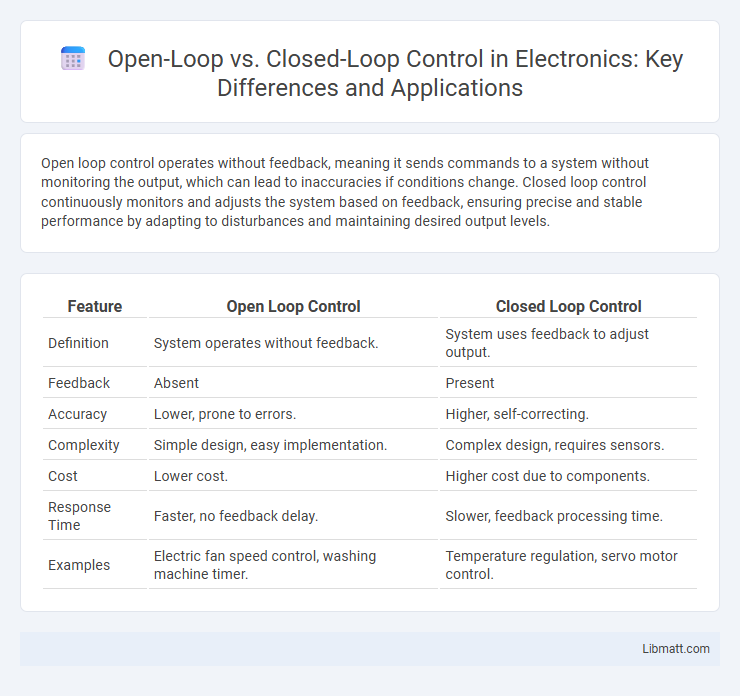

Open loop control operates without feedback, meaning it sends commands to a system without monitoring the output, which can lead to inaccuracies if conditions change. Closed loop control continuously monitors and adjusts the system based on feedback, ensuring precise and stable performance by adapting to disturbances and maintaining desired output levels.

Table of Comparison

| Feature | Open Loop Control | Closed Loop Control |

|---|---|---|

| Definition | System operates without feedback. | System uses feedback to adjust output. |

| Feedback | Absent | Present |

| Accuracy | Lower, prone to errors. | Higher, self-correcting. |

| Complexity | Simple design, easy implementation. | Complex design, requires sensors. |

| Cost | Lower cost. | Higher cost due to components. |

| Response Time | Faster, no feedback delay. | Slower, feedback processing time. |

| Examples | Electric fan speed control, washing machine timer. | Temperature regulation, servo motor control. |

Introduction to Control Systems

Control systems regulate the behavior of devices or processes using feedback mechanisms that distinguish open loop from closed loop control. Open loop control operates without feedback, executing predetermined commands regardless of output changes, while closed loop control continuously monitors output and adjusts inputs to achieve desired performance. Understanding these systems helps you select the appropriate control strategy for applications requiring accuracy, stability, and adaptability.

What is Open Loop Control?

Open Loop Control is a system where the output is not measured or fed back for comparison with the input, meaning it operates solely based on pre-set instructions without adjusting to real-time changes. This control method is effective in situations where the process is predictable and disturbances are minimal, but it lacks the ability to correct errors automatically. You rely on Open Loop Control when precision feedback is unnecessary or cost-prohibitive, as it offers simplicity and lower implementation costs.

What is Closed Loop Control?

Closed Loop Control is a feedback-based system where the output continuously influences the input to maintain desired performance. Sensors monitor the process variable, and the controller adjusts actions based on deviations from the setpoint, ensuring accuracy and stability. This type of control is essential in applications requiring precision, such as temperature regulation, motor speed control, and automated manufacturing systems.

Key Differences Between Open Loop and Closed Loop Systems

Open loop control systems operate without feedback, executing predetermined commands regardless of output conditions, making them simpler but less accurate. Closed loop control systems continuously monitor output via sensors, adjusting inputs dynamically to maintain desired performance, resulting in higher precision and adaptability. The key differences include feedback presence, error correction capability, and system complexity, with closed loop systems providing superior control in variable environments.

Advantages of Open Loop Control

Open Loop Control systems offer simplicity and cost-effectiveness by operating without feedback, making them easier to design and maintain. Their fast response is beneficial in applications where the process behavior is well understood and disturbances are minimal. You benefit from increased reliability since fewer components reduce the chances of failure and reduce system complexity.

Advantages of Closed Loop Control

Closed loop control systems provide precise regulation by continuously monitoring output and adjusting inputs to maintain desired performance, resulting in enhanced accuracy and stability. These systems effectively compensate for disturbances and system uncertainties, ensuring consistent operation even in dynamic environments. Their feedback mechanism reduces errors and improves reliability, making them ideal for complex applications requiring real-time adjustments.

Disadvantages and Limitations of Open Loop Systems

Open loop control systems cannot correct errors or disturbances during operation, leading to reduced accuracy and reliability in dynamic environments. Their lack of feedback makes them unsuitable for processes requiring precise control or adaptation to changing conditions. Dependence on initial input without real-time adjustments increases the risk of system failure when unexpected variations occur.

Disadvantages and Limitations of Closed Loop Systems

Closed loop control systems face limitations such as increased system complexity and higher costs due to the need for sensors and feedback mechanisms. They may exhibit slower response times compared to open loop systems because of continuous monitoring and corrective actions. Moreover, closed loop systems can be susceptible to sensor noise, leading to potential instability or inaccurate control performance.

Practical Applications: Open Loop vs Closed Loop

Open loop control systems are ideal for simple, repetitive tasks like conveyor belt operation and irrigation systems where feedback is unnecessary. Closed loop control excels in applications requiring precision and adaptability, such as temperature regulation in HVAC systems and automated robotic arms in manufacturing. Your choice between open loop and closed loop control depends on the need for accuracy, system complexity, and response to environmental changes.

Choosing the Right Control System for Your Needs

Selecting between open loop and closed loop control systems depends on the application's precision and feedback requirements. Open loop control is suitable for simple, predictable tasks where system conditions remain constant, minimizing cost and complexity. Closed loop control systems offer enhanced accuracy and adaptability by continuously monitoring output and adjusting inputs, making them ideal for dynamic environments requiring precise regulation.

Open Loop vs Closed Loop Control Infographic

libmatt.com

libmatt.com