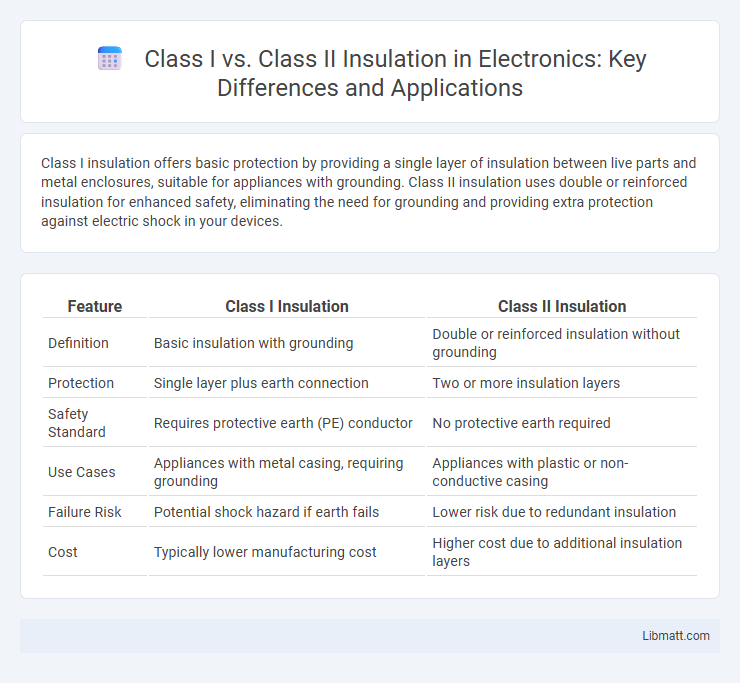

Class I insulation offers basic protection by providing a single layer of insulation between live parts and metal enclosures, suitable for appliances with grounding. Class II insulation uses double or reinforced insulation for enhanced safety, eliminating the need for grounding and providing extra protection against electric shock in your devices.

Table of Comparison

| Feature | Class I Insulation | Class II Insulation |

|---|---|---|

| Definition | Basic insulation with grounding | Double or reinforced insulation without grounding |

| Protection | Single layer plus earth connection | Two or more insulation layers |

| Safety Standard | Requires protective earth (PE) conductor | No protective earth required |

| Use Cases | Appliances with metal casing, requiring grounding | Appliances with plastic or non-conductive casing |

| Failure Risk | Potential shock hazard if earth fails | Lower risk due to redundant insulation |

| Cost | Typically lower manufacturing cost | Higher cost due to additional insulation layers |

Introduction to Electrical Insulation Classes

Class I and Class II electrical insulation refer to standards that define the level of protection against electric shock for electrical appliances. Class I insulation requires a grounding system to protect users by connecting exposed metal parts to earth, ensuring safety in case of insulation failure. Class II insulation, known as double insulation, incorporates two layers of insulation or reinforced insulation that eliminate the need for grounding, providing enhanced safety for devices without a grounding conductor, which can be crucial for your electrical installations.

Overview of Class I Insulation

Class I insulation primarily serves as the basic protective layer for electrical equipment, providing resistance to heat, moisture, and mechanical damage. It is designed to handle temperature ranges typically up to 105degC (221degF) and is widely used in motors, transformers, and generators. You can rely on Class I insulation to ensure safe operation and longevity in standard industrial and commercial applications.

Overview of Class II Insulation

Class II insulation provides enhanced safety by offering double or reinforced insulation, eliminating the need for a grounded metal casing or earth connection. This insulation type is commonly used in electrical appliances and devices that require protection against electric shock, ensuring compliance with international safety standards like IEC 61140. Class II insulation materials typically include multiple layers of non-conductive substances such as plastic or rubber to achieve the required protective barrier.

Key Differences Between Class I and Class II Insulation

Class I insulation requires an earth connection and offers basic protection against electric shock, making it suitable for devices with metal parts that could become live. Class II insulation features double or reinforced insulation, eliminating the need for an earth wire and providing enhanced safety by preventing electric shock even if one layer of insulation fails. Understanding these key differences helps ensure your equipment meets safety standards and protects users effectively.

Safety Standards and Regulations for Insulation Classes

Class I insulation adheres to safety standards defined by IEC 60085, addressing basic insulation requirements to prevent electrical shock under normal operating conditions. Class II insulation meets stricter regulations including double or reinforced insulation standards without a grounding conductor, complying with IEC 61140 for enhanced user protection in fault conditions. Regulatory compliance for both classes ensures reliable performance in electrical appliances, with Class II providing higher safety margins in environments prone to moisture or mechanical damage.

Applications of Class I Insulated Equipment

Class I insulated equipment is primarily used in environments where grounding is available and essential for safety, such as industrial machinery, household appliances, and power tools. This type of insulation relies on a grounded metal enclosure to protect users from electric shock, making it suitable for applications where robust earthing systems are in place. Your choice of Class I equipment ensures compliance with safety standards in settings demanding reliable grounding protection.

Applications of Class II Insulated Equipment

Class II insulation is commonly used in low-voltage applications such as household electronics, portable appliances, and medical devices, where enhanced protection against electric shock is critical. This insulation type relies on a double or reinforced insulation system, eliminating the need for grounding and making it ideal for devices operated in damp or outdoor environments. Your choice of Class II insulated equipment ensures safer operation without the requirement of a protective earth connection, significantly reducing the risk of electrical hazards.

Advantages and Limitations of Class I Insulation

Class I insulation offers superior thermal resistance and durability, making it ideal for heavy-duty electrical equipment and environments with high temperatures. Its robust protective properties ensure enhanced safety by preventing electrical faults and reducing the risk of fire hazards. You should consider that Class I insulation typically requires a grounding system, which can increase installation complexity and overall costs compared to Class II insulation.

Advantages and Limitations of Class II Insulation

Class II insulation offers enhanced safety by providing double or reinforced insulation, effectively eliminating the need for an earth connection and reducing the risk of electric shock. Its design allows for greater versatility in electrical appliances, making it ideal for consumer electronics with exposed metal parts. However, Class II insulation can be more costly to manufacture and may require thicker layers of insulating material, potentially increasing the size and weight of the final product.

Choosing the Right Insulation Class for Your Needs

Selecting the appropriate insulation class between Class I and Class II depends primarily on the operating temperature requirements of your electrical equipment. Class I insulation typically withstands temperatures up to 105degC, making it suitable for standard applications, while Class II insulation can handle higher temperatures up to 130degC, ideal for more demanding environments. Evaluating the specific thermal demands and safety standards of your project ensures optimal performance and longevity of the insulation material.

Class I vs Class II insulation Infographic

libmatt.com

libmatt.com