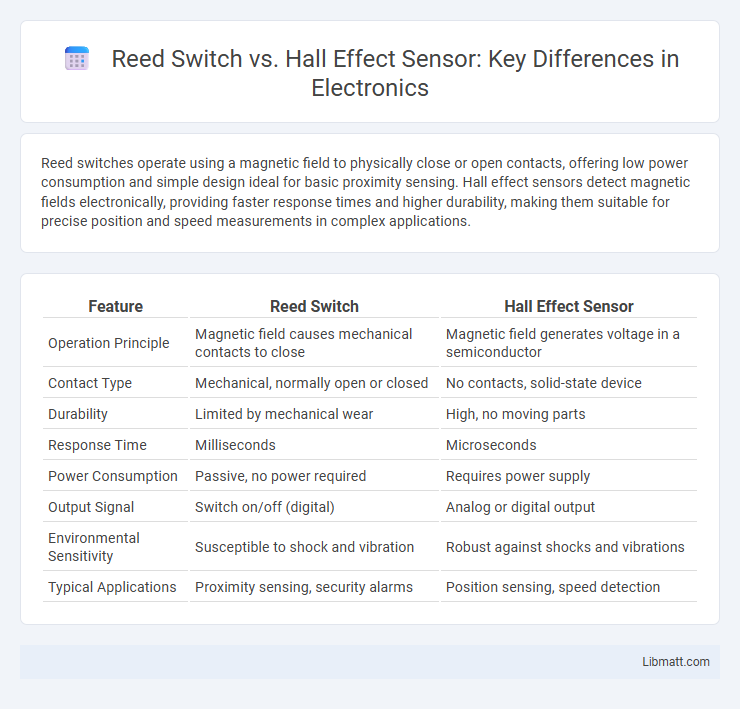

Reed switches operate using a magnetic field to physically close or open contacts, offering low power consumption and simple design ideal for basic proximity sensing. Hall effect sensors detect magnetic fields electronically, providing faster response times and higher durability, making them suitable for precise position and speed measurements in complex applications.

Table of Comparison

| Feature | Reed Switch | Hall Effect Sensor |

|---|---|---|

| Operation Principle | Magnetic field causes mechanical contacts to close | Magnetic field generates voltage in a semiconductor |

| Contact Type | Mechanical, normally open or closed | No contacts, solid-state device |

| Durability | Limited by mechanical wear | High, no moving parts |

| Response Time | Milliseconds | Microseconds |

| Power Consumption | Passive, no power required | Requires power supply |

| Output Signal | Switch on/off (digital) | Analog or digital output |

| Environmental Sensitivity | Susceptible to shock and vibration | Robust against shocks and vibrations |

| Typical Applications | Proximity sensing, security alarms | Position sensing, speed detection |

Introduction to Reed Switches and Hall Effect Sensors

Reed switches consist of two ferromagnetic blades sealed within a glass tube that close or open an electrical circuit in response to an external magnetic field, making them ideal for simple on/off sensing applications. Hall effect sensors detect magnetic fields by producing a voltage proportional to the strength of the magnetic flux, enabling precise and contactless measurement of position, speed, or current. Compared to reed switches, Hall effect sensors offer faster response times, longer lifespan due to solid-state design, and greater sensitivity for advanced electronic systems.

How Reed Switches Work

Reed switches operate through the magnetic attraction of thin ferromagnetic reeds enclosed in a glass envelope, which close or open an electrical circuit when exposed to a magnetic field. The movement of the reeds creates a mechanical contact that either completes or breaks the circuit, allowing for simple, reliable switching without requiring external power. These switches are highly sensitive to magnetic fields, making them ideal for detecting position, proximity, or speed in various industrial and consumer applications.

How Hall Effect Sensors Work

Hall Effect sensors operate by detecting magnetic fields through the Hall voltage generated when a conductor carrying current is placed in a magnetic field perpendicular to the current direction. This voltage variation is converted into an electrical signal proportional to the magnetic field strength, enabling precise position, speed, or proximity measurement. Unlike Reed switches that rely on physical contact closure, Hall Effect sensors offer non-contact, wear-free operation with higher durability and faster response times.

Key Differences Between Reed Switches and Hall Effect Sensors

Reed switches rely on magnetic contact closure, using ferromagnetic reeds that physically touch when exposed to a magnetic field, making them ideal for simple on/off sensing with low power consumption. Hall Effect sensors detect magnetic fields through semiconductor technology, providing analog or digital output with faster response time, improved durability, and the ability to measure magnetic field strength accurately. Your choice depends on the application's need for precision, switching speed, and environmental robustness.

Advantages of Reed Switches

Reed switches offer low power consumption and operate without a continuous electrical supply, making them ideal for battery-powered applications. Their simple mechanical design provides excellent reliability and durability in harsh environments with high resistance to radiation and electromagnetic interference. Reed switches also ensure fast switching speeds and cost-effective solutions for proximity sensing and switching tasks.

Benefits of Hall Effect Sensors

Hall Effect sensors offer significant benefits over reed switches, including greater durability and longer lifespan due to the absence of mechanical contacts, which eliminates wear and tear. They provide higher precision and faster response times for more accurate magnetic field detection in various applications. You can rely on Hall Effect sensors for enhanced reliability in harsh environments where reed switches might fail.

Common Applications of Reed Switches

Reed switches are widely used in applications such as security systems for door and window sensors, proximity detection in industrial machinery, and automotive systems for position sensing. Their simple design and reliable operation in detecting magnetic fields make them ideal for tasks requiring low power consumption and high sensitivity. Your choice of reed switches is beneficial in environments where mechanical contact is preferred for precise, on/off sensing without the need for power to hold the state.

Typical Uses for Hall Effect Sensors

Hall Effect sensors are widely used in automotive applications for speed detection, position sensing, and current measurement due to their reliability and contactless operation. They are also essential in consumer electronics for proximity sensing and in industrial equipment for precise motor control and robotic positioning. Their durability and ability to operate in harsh environments make them ideal for applications requiring accurate, non-contact sensing.

Choosing the Right Sensor for Your Project

Choosing the right sensor for your project depends on factors like sensitivity, size, and environmental conditions. Reed switches excel in simplicity and low power consumption, making them ideal for detecting magnetic fields in low-voltage applications. Hall effect sensors offer higher precision, durability, and analog output options, suitable for projects requiring continuous position or speed measurements.

Conclusion: Reed Switch vs Hall Effect Sensor

Reed switches provide a simple, cost-effective solution for detecting magnetic fields with mechanical durability but are limited by slower response times and physical wear. Hall effect sensors offer faster, contactless operation with higher reliability and are better suited for high-speed or continuously varying magnetic field applications. Choosing between the two depends on specific requirements such as switching speed, durability, and environmental conditions.

Reed Switch vs Hall Effect Infographic

libmatt.com

libmatt.com