A synchronous buck converter uses MOSFETs for both the high-side and low-side switches, improving efficiency by reducing conduction losses compared to an asynchronous buck converter, which uses a diode for the low-side switch. Your choice between synchronous and asynchronous buck converters depends on factors like efficiency requirements, cost, and complexity of the application.

Table of Comparison

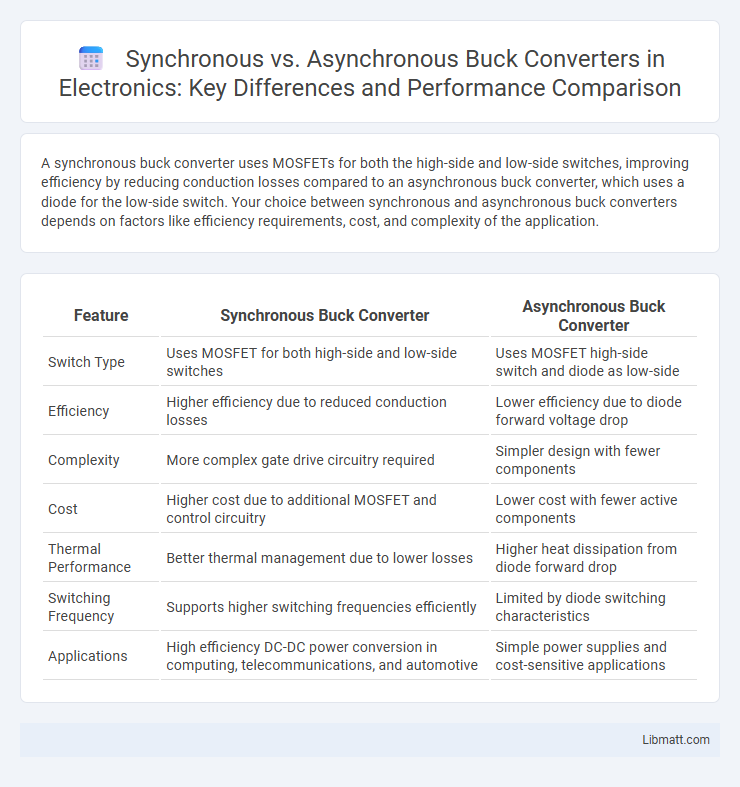

| Feature | Synchronous Buck Converter | Asynchronous Buck Converter |

|---|---|---|

| Switch Type | Uses MOSFET for both high-side and low-side switches | Uses MOSFET high-side switch and diode as low-side |

| Efficiency | Higher efficiency due to reduced conduction losses | Lower efficiency due to diode forward voltage drop |

| Complexity | More complex gate drive circuitry required | Simpler design with fewer components |

| Cost | Higher cost due to additional MOSFET and control circuitry | Lower cost with fewer active components |

| Thermal Performance | Better thermal management due to lower losses | Higher heat dissipation from diode forward drop |

| Switching Frequency | Supports higher switching frequencies efficiently | Limited by diode switching characteristics |

| Applications | High efficiency DC-DC power conversion in computing, telecommunications, and automotive | Simple power supplies and cost-sensitive applications |

Introduction to Buck Converters

Buck converters efficiently step down voltage while maintaining high power conversion efficiency. Synchronous buck converters use MOSFETs for both the high-side and low-side switches, reducing conduction losses compared to asynchronous designs that use a diode for the low-side switch. Your choice between synchronous and asynchronous buck converters impacts efficiency, thermal performance, and overall power management in electronic systems.

Overview of Synchronous and Asynchronous Topologies

Synchronous buck converters utilize MOSFETs for both the high-side and low-side switches, improving efficiency by reducing conduction losses compared to asynchronous buck converters, which use a diode as the low-side component. The synchronous topology allows for better control and higher power density, particularly in low-voltage, high-current applications. Asynchronous buck converters are simpler and more cost-effective but suffer from lower efficiency due to the diode's inherent forward voltage drop and higher power dissipation.

Key Components and Circuit Design

Synchronous buck converters use MOSFETs for both the high-side and low-side switches, which reduces conduction losses and improves efficiency compared to asynchronous converters that use a diode for the low-side switch. Key components in synchronous designs include the high-side and low-side MOSFETs, gate drivers, and an inductor to smooth the output current, while asynchronous designs replace the low-side MOSFET with a diode, simplifying the circuit but increasing power dissipation. Your choice of circuit design impacts efficiency, thermal performance, and component size, with synchronous converters favored for applications requiring higher efficiency and better thermal management.

Efficiency Comparison: Synchronous vs Asynchronous

Synchronous buck converters achieve higher efficiency than asynchronous designs by replacing the diode with a low-resistance MOSFET, significantly reducing conduction losses during the switching cycle. Asynchronous converters rely on a diode for the lower switch, resulting in higher power dissipation and heat generation, especially at higher currents. Your choice impacts overall system efficiency and thermal management, with synchronous designs favored in power-sensitive applications for maximizing energy savings.

Switching Losses and Heat Management

Synchronous buck converters significantly reduce switching losses by replacing the diode with a low-resistance MOSFET, leading to higher efficiency and less heat generation compared to asynchronous designs. Lower conduction losses in synchronous converters improve thermal performance, minimizing the need for extensive heat sinks and enabling compact, high-density power solutions. Asynchronous buck converters typically suffer from higher switching losses due to diode forward voltage drop, resulting in greater heat dissipation and more complex thermal management strategies.

Cost and Complexity Considerations

Synchronous buck converters generally have higher initial cost and increased design complexity due to the use of additional MOSFETs and control circuitry, which enhances efficiency but requires careful layout and gate drive design. Asynchronous buck converters are simpler and less expensive, utilizing a diode instead of a synchronous MOSFET, making them suitable for cost-sensitive applications with moderate efficiency requirements. Your choice between the two should balance budget constraints and performance needs, as synchronous designs offer better efficiency at a premium, while asynchronous options reduce cost and complexity.

Performance in Light-Load and Heavy-Load Conditions

Synchronous buck converters exhibit higher efficiency in heavy-load conditions due to the use of MOSFETs, which reduce conduction losses compared to diodes found in asynchronous designs. Asynchronous buck converters often perform better in light-load conditions by benefiting from simpler control and lower quiescent current, making them ideal for low-power standby modes. Performance optimization in both converter types depends on factors such as switching frequency, gate drive losses, and inductor selection, which influence efficiency across varying load demands.

Applications and Use Cases

Synchronous buck converters are ideal for high-efficiency applications such as CPUs, GPUs, and power management in portable electronics where tight voltage regulation and low power loss are critical. Asynchronous buck converters suit less demanding applications like DC motor drives, battery chargers, and power supplies where cost and simplicity are prioritized over maximum efficiency. Understanding your specific power requirements helps determine the most suitable converter for your use case.

Design Challenges and Solutions

Synchronous buck converters face design challenges including higher complexity due to the integration of MOSFETs replacing diodes, which demands precise gate drive timing to prevent shoot-through and reduce switching losses. Asynchronous buck converters are simpler but suffer from lower efficiency and higher power dissipation due to diode conduction losses, especially at low output voltages. Solutions for synchronous designs involve using advanced gate drivers and adaptive dead-time control to optimize switching transitions, while asynchronous designs benefit from selecting low forward voltage drop Schottky diodes to improve efficiency.

Selecting the Right Buck Converter for Your Needs

Choosing the right buck converter depends on power efficiency, complexity, and cost considerations. Synchronous buck converters offer higher efficiency and better thermal performance by replacing the diode with a controlled MOSFET, reducing conduction losses during switching. For applications requiring low power consumption and extended battery life, your choice should favor synchronous designs, while asynchronous buck converters remain suitable for simpler, cost-sensitive projects.

Synchronous vs Asynchronous buck converter Infographic

libmatt.com

libmatt.com