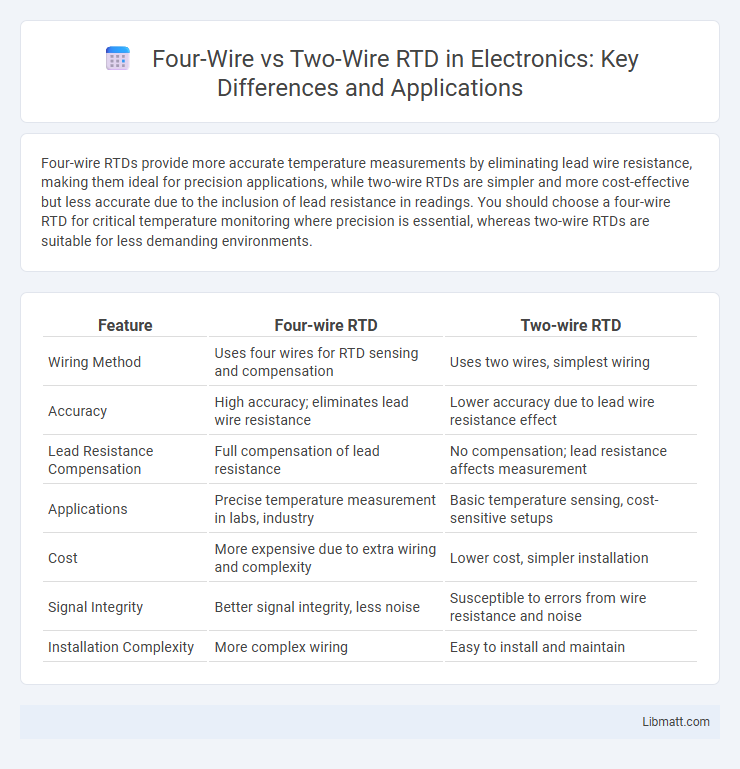

Four-wire RTDs provide more accurate temperature measurements by eliminating lead wire resistance, making them ideal for precision applications, while two-wire RTDs are simpler and more cost-effective but less accurate due to the inclusion of lead resistance in readings. You should choose a four-wire RTD for critical temperature monitoring where precision is essential, whereas two-wire RTDs are suitable for less demanding environments.

Table of Comparison

| Feature | Four-wire RTD | Two-wire RTD |

|---|---|---|

| Wiring Method | Uses four wires for RTD sensing and compensation | Uses two wires, simplest wiring |

| Accuracy | High accuracy; eliminates lead wire resistance | Lower accuracy due to lead wire resistance effect |

| Lead Resistance Compensation | Full compensation of lead resistance | No compensation; lead resistance affects measurement |

| Applications | Precise temperature measurement in labs, industry | Basic temperature sensing, cost-sensitive setups |

| Cost | More expensive due to extra wiring and complexity | Lower cost, simpler installation |

| Signal Integrity | Better signal integrity, less noise | Susceptible to errors from wire resistance and noise |

| Installation Complexity | More complex wiring | Easy to install and maintain |

Introduction to RTDs

RTDs (Resistance Temperature Detectors) measure temperature by correlating resistance changes in a metal element, typically platinum, with temperature variations. Four-wire RTDs provide the highest accuracy by eliminating lead wire resistance errors, making them ideal for precise temperature measurements in critical applications. Two-wire RTDs are simpler and cost-effective but can introduce measurement inaccuracies due to lead resistance, affecting your temperature reading reliability.

Understanding Two-Wire RTD Configuration

Two-wire RTD configurations are the simplest type, using only two leads to measure resistance, but they are prone to inaccuracies due to lead wire resistance affecting the measurement. This setup is commonly found in applications where cost and simplicity are prioritized over precision, as the lead resistance adds directly to the sensor resistance, causing errors. For accurate temperature measurement, environments with stable lead lengths and minimal wire resistance changes are preferable when using two-wire RTDs.

Exploring Four-Wire RTD Configuration

Four-wire RTD configuration offers the highest accuracy by eliminating lead wire resistance from temperature measurements, making it ideal for precision applications. Unlike two-wire RTDs, the four-wire setup uses separate pairs for current supply and voltage sensing, ensuring minimal error due to lead resistance. Your temperature monitoring system benefits from this enhanced reliability, especially in critical industrial environments demanding exact temperature control.

Key Differences Between Two-Wire and Four-Wire RTDs

Two-wire RTDs use a simple connection where the lead wire resistance directly affects the measurement accuracy, making them less precise in applications requiring high accuracy. Four-wire RTDs eliminate lead wire resistance errors by using separate pairs of wires for current and voltage measurement, ensuring more accurate temperature readings. Your choice depends on the required measurement precision and the complexity you can accommodate in your temperature sensing setup.

Accuracy Comparison: Two-Wire vs Four-Wire RTD

Four-wire RTDs offer superior accuracy compared to two-wire RTDs by eliminating lead wire resistance from measurement. Two-wire RTDs introduce measurement errors due to resistance in the lead wires, which can cause deviations especially in long-distance or high-precision applications. Four-wire configurations use separate pairs for current supply and voltage measurement, ensuring precise temperature readings by effectively canceling out lead resistance effects.

Wiring Complexity and Installation Considerations

Four-wire RTDs offer superior accuracy by eliminating lead wire resistance effects, requiring four separate wires, which increases wiring complexity and installation time. Two-wire RTDs are simpler with only two leads, reducing installation effort and cost, but they are more susceptible to measurement errors caused by lead resistance. Choosing between four-wire and two-wire configurations depends on the required measurement precision and available installation resources.

Cost Implications of Two-Wire and Four-Wire RTDs

Two-wire RTDs are more cost-effective due to simpler wiring and reduced material use, making them ideal for budget-sensitive applications. Four-wire RTDs, while more expensive initially because of additional leads and connectors, provide superior accuracy by eliminating lead wire resistance errors, which can save costs in precision-critical environments by minimizing calibration and maintenance needs. Your choice depends on balancing upfront expenses with long-term performance requirements.

Applications Suitable for Two-Wire RTDs

Two-wire RTDs are commonly used in applications where cost-efficiency and simplicity are prioritized, such as HVAC systems, household appliances, and basic industrial processes with stable ambient conditions. These sensors are suitable for short-distance temperature measurements where lead wire resistance has minimal impact on accuracy. Two-wire RTDs provide adequate performance in environments with minimal electrical noise and limited wiring complexity.

Applications Benefiting from Four-Wire RTDs

Four-wire RTDs provide superior accuracy by eliminating lead wire resistance, making them ideal for precision temperature measurements in industrial processes, such as chemical manufacturing and aerospace testing. Your applications involving long wire runs or very low resistance sensing benefit significantly from four-wire configurations, ensuring reliable data without interference. In contrast, two-wire RTDs are better suited for simpler, short-distance setups with less stringent accuracy requirements.

Choosing the Right RTD Configuration for Your Needs

Four-wire RTDs offer the highest accuracy by eliminating lead wire resistance effects, making them ideal for precision temperature measurements in critical applications. Two-wire RTDs are simpler and more cost-effective but may introduce measurement errors due to lead resistance, suitable for less demanding environments. Your choice depends on the required measurement accuracy and budget constraints, with four-wire configurations recommended for high-precision needs and two-wire for general use.

Four-wire vs Two-wire RTD Infographic

libmatt.com

libmatt.com