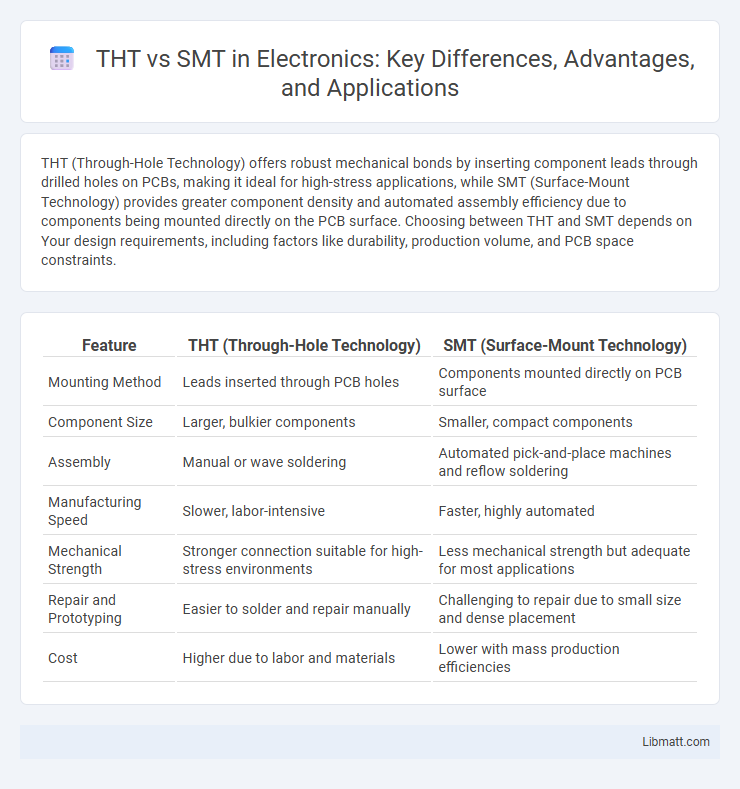

THT (Through-Hole Technology) offers robust mechanical bonds by inserting component leads through drilled holes on PCBs, making it ideal for high-stress applications, while SMT (Surface-Mount Technology) provides greater component density and automated assembly efficiency due to components being mounted directly on the PCB surface. Choosing between THT and SMT depends on Your design requirements, including factors like durability, production volume, and PCB space constraints.

Table of Comparison

| Feature | THT (Through-Hole Technology) | SMT (Surface-Mount Technology) |

|---|---|---|

| Mounting Method | Leads inserted through PCB holes | Components mounted directly on PCB surface |

| Component Size | Larger, bulkier components | Smaller, compact components |

| Assembly | Manual or wave soldering | Automated pick-and-place machines and reflow soldering |

| Manufacturing Speed | Slower, labor-intensive | Faster, highly automated |

| Mechanical Strength | Stronger connection suitable for high-stress environments | Less mechanical strength but adequate for most applications |

| Repair and Prototyping | Easier to solder and repair manually | Challenging to repair due to small size and dense placement |

| Cost | Higher due to labor and materials | Lower with mass production efficiencies |

Introduction to THT and SMT Technologies

Through-Hole Technology (THT) involves inserting electronic component leads through pre-drilled holes on a printed circuit board (PCB) and soldering them on the opposite side, providing strong mechanical bonds ideal for heavy components. Surface-Mount Technology (SMT) places components directly onto the surface of the PCB without the need for drilled holes, enabling higher component density and automated manufacturing processes. Your choice between THT and SMT impacts factors like assembly speed, cost, and the mechanical strength required for the application.

Key Differences Between THT and SMT

Through-Hole Technology (THT) involves inserting component leads through drilled holes on a printed circuit board (PCB), providing strong mechanical bonds ideal for heavy or high-stress components. Surface-Mount Technology (SMT) places components directly onto the PCB surface, enabling smaller, more compact designs with automated assembly and higher component density. You should choose SMT for modern, high-volume production and THT where durability and mechanical strength are critical.

Historical Evolution of THT and SMT

Through the historical evolution of electronics manufacturing, Through-Hole Technology (THT) dominated early circuit assembly due to its strong mechanical connections and ease of prototyping. Surface-Mount Technology (SMT) emerged in the late 20th century, revolutionizing the industry with smaller components, increased circuit density, and faster production times. Understanding this progression helps you choose the appropriate technology for your specific electronic design requirements.

Advantages of Through-Hole Technology (THT)

Through-Hole Technology (THT) offers superior mechanical strength and enhanced durability, making it ideal for components subject to physical stress or high-reliability applications. THT provides better electrical performance in high-power and high-frequency circuits due to reduced parasitic inductance and capacitance. Its ease of manual inspection, testing, and repair simplifies maintenance and prototyping compared to Surface-Mount Technology (SMT).

Benefits of Surface-Mount Technology (SMT)

Surface-Mount Technology (SMT) offers significant advantages including higher component density, enabling more compact and lightweight circuit designs. SMT improves electrical performance by minimizing lead lengths and reducing parasitic inductance and capacitance. The automation-friendly nature of SMT enhances manufacturing speed and precision, lowering production costs and increasing reliability.

Common Applications of THT vs SMT

THT (Through-Hole Technology) is commonly used in applications requiring strong mechanical bonds, such as connectors, switches, and high-reliability components in aerospace and military electronics. SMT (Surface-Mount Technology) dominates in high-density circuit boards like smartphones, computers, and consumer electronics due to its smaller component size and automated assembly efficiency. Your choice between THT and SMT depends on the specific mechanical strength and miniaturization requirements of the electronic device.

Challenges Faced in THT and SMT Assembly

THT (Through-Hole Technology) assembly faces challenges such as labor-intensive manual insertion, higher assembly time, and difficulty in achieving high component density, impacting production efficiency. SMT (Surface-Mount Technology) assembly struggles with issues like solder joint reliability, dealing with tiny component sizes requiring precise placement, and potential defects from solder paste application and reflow processes. Both technologies require careful process control to minimize defects and ensure optimal electrical performance in electronic manufacturing.

Cost Comparison: THT vs SMT

Through-Hole Technology (THT) generally incurs higher manufacturing costs due to manual assembly processes and larger hole drilling on PCBs, whereas Surface-Mount Technology (SMT) benefits from automated placement and smaller component footprints, reducing labor and material expenses. SMT enables higher component density and faster production times, resulting in lower per-unit costs compared to THT's more labor-intensive procedures. For large-scale, high-volume production, SMT offers significant cost advantages, while THT remains more cost-effective for prototyping or low-volume runs requiring robust mechanical connections.

Future Trends in PCB Assembly: THT and SMT

Future trends in PCB assembly indicate a growing dominance of Surface-Mount Technology (SMT) due to its suitability for miniaturization and high-density component placement. Through-Hole Technology (THT) remains essential for applications requiring strong mechanical bonds and high reliability in harsh environments. Advances in hybrid assembly techniques are emerging to combine the strengths of THT and SMT, enhancing overall performance and manufacturing efficiency in complex electronic devices.

Conclusion: Choosing Between THT and SMT

Through-Hole Technology (THT) offers strong mechanical bonds ideal for heavy components and high durability, while Surface-Mount Technology (SMT) excels in high-density, compact circuit designs with automated assembly benefits. Selecting between THT and SMT depends on factors like board space, component size, production volume, and mechanical stress requirements. For mass production of miniaturized devices, SMT is preferred, whereas THT remains suitable for prototypes, repairs, or components requiring enhanced mechanical strength.

THT vs SMT Infographic

libmatt.com

libmatt.com